Climbing truss robot capable of swinging and grasping long-distance truss rods and control method thereof

A technology of truss robots and truss rods, applied in the field of climbing truss robots and their control, can solve problems such as the inability to reliably grasp far truss rods, continuous movement of truss structures, etc., and achieve accurate motion state feedback and fast excitation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

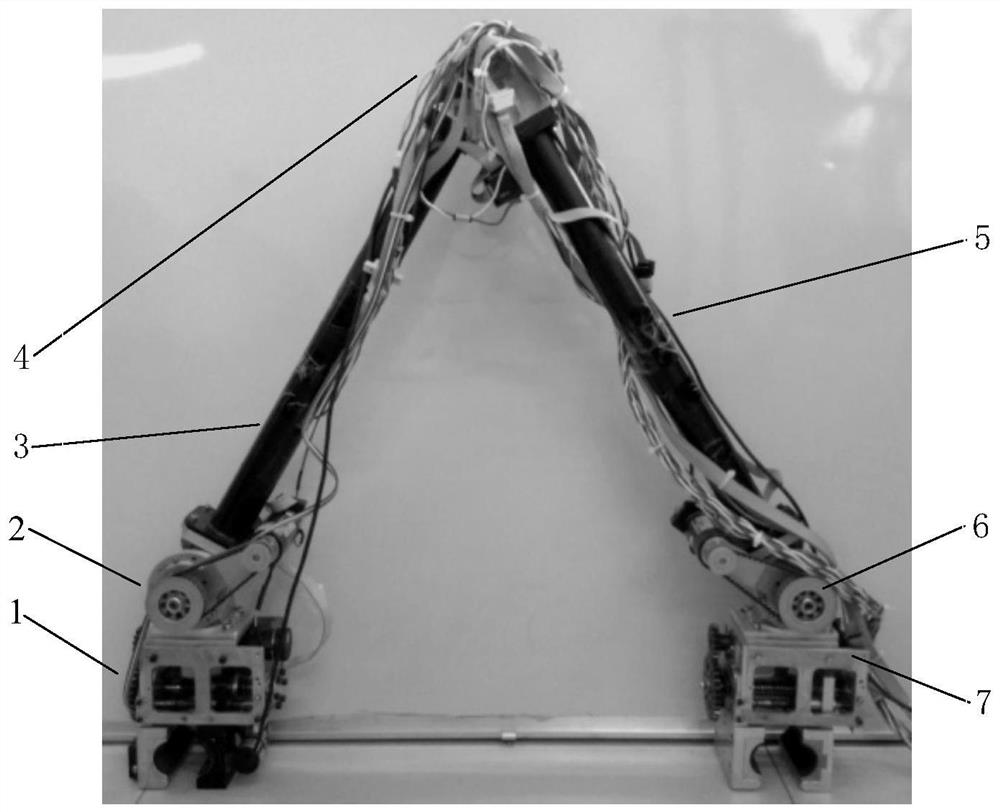

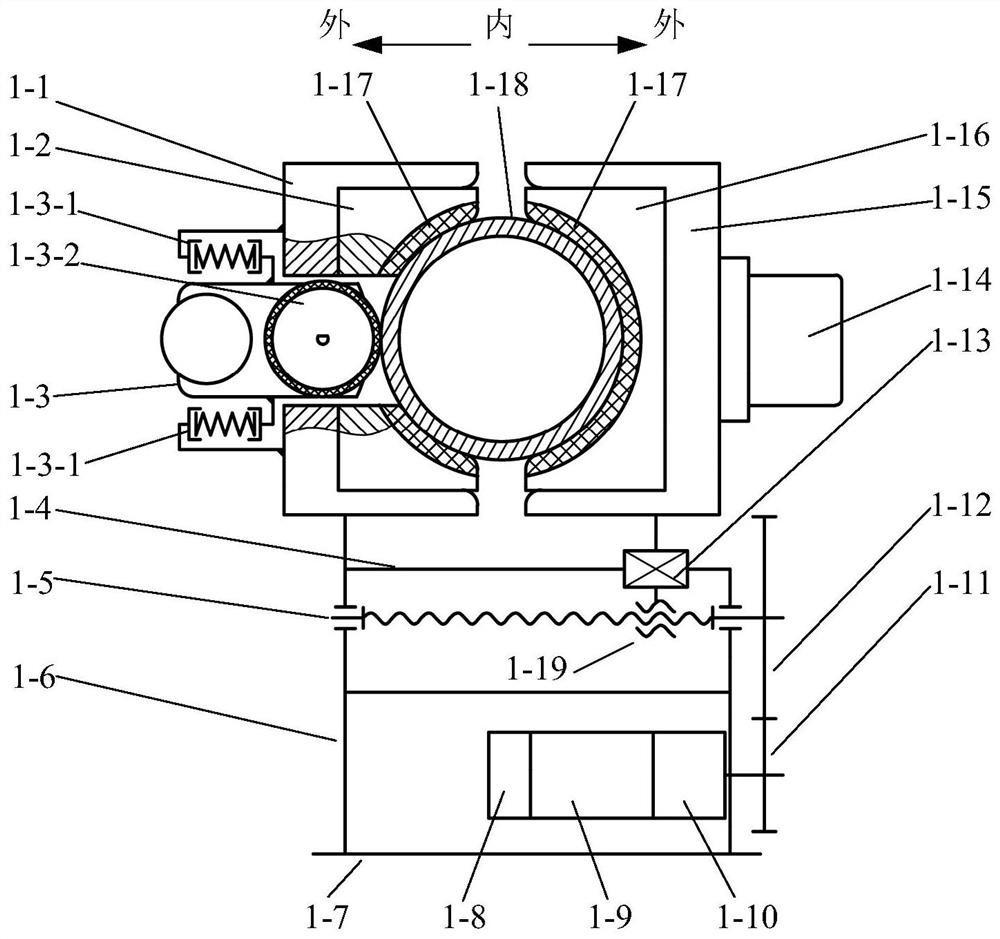

[0096] Specific implementation mode one: as Figure 1~4 As shown, the improved climbing truss robot in this embodiment includes a first gripper 1, a first wrist joint 2, a first connecting rod 3, an elbow joint 4, a second connecting rod 5, a second wrist joint 6 and a second Claw 7, the first claw 1 is rotatably connected to one end of the first connecting rod 3 through the first wrist joint 2, and the other end of the first connecting rod 3 is rotatably connected to one end of the second connecting rod 5 through the elbow joint 4. The second hand claw 7 is rotationally connected with the other end of the second connecting rod 5 through the second wrist joint 6; the first claw 1 and the second claw 7 are the same part, and the first wrist joint 2 and the second wrist joint 6 are the same Parts, the first connecting rod 3 and the second connecting rod 5 are the same part. The first wrist joint 2, the elbow joint 4, and the second wrist joint 6 are all composed of a DC servo m...

specific Embodiment approach 2

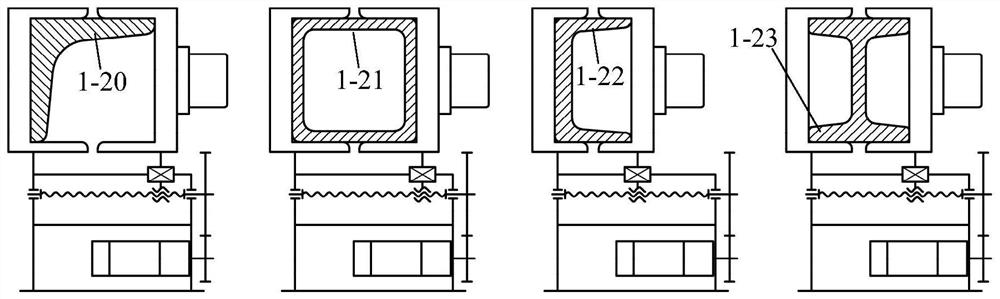

[0098] Specific implementation mode two: as figure 2 , 3 As shown, when the truss rod to be grasped is a truss rod 1-18 with a circular cross section, the opening and closing claws of the robot can be respectively loaded into the fixed half claw 1-1 and the moving half claw 1-15. Claw bushing 1-2 and moving claw bushing 1-16, and different friction materials 1-17 can be selected according to the material and surface roughness of the truss rod 1-18. For large rubber materials, the wear-resistant silicone material can be used to grasp the hard and rough surface, and the asbestos layer with good chimerism can be used to grasp the soft uneven surface such as cables. For truss rods with 90° corners such as angle steel 1-20, square steel 1-21, channel steel 1-22, and I-beam 1-23, the fixed claw bushing 1-2 and movable claw bushing can be removed Cover 1-16, using the rectangular slots on the inside of the fixed half-claw 1-1 and the moving half-claw 1-15 to grasp. The rectangula...

specific Embodiment approach 3

[0099] Specific implementation mode three: as Figure 5 As shown, the control system of the climbing truss robot is composed of the host computer and the servo motor control / driver of the first gripper 1, the first wrist joint 2, the elbow joint 4, the second wrist joint 6, and the second gripper 7 , the upper computer communicates with the master node servo control / driver that drives and controls the DC servo motor 1-9 in the first gripper 1 through the USB interface, and the master node servo control / driver communicates with other servo control / drivers through the CAN bus, each The servo control / driver corresponds to a DC servo motor. The upper computer can also install a CAN-PCI board on the PCI slot, through which it can directly communicate with all servo controllers / drivers. The friction wheel retreat feedback mechanism 1-3 on the robot claw feeds back the rotation angle θ of the photoelectric encoder shaft inside it, the gyroscope 1-14 feeds back its own rotational ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com