Magnetic current change polishing solution circulating device capable of long-time steadily polishing solution performance

A technology of magnetorheological polishing and polishing fluid, which is applied in the field of magnetorheological polishing, can solve problems such as no control, difficult high-precision optical parts modification and polishing, and change of magnetorheological polishing fluid, so as to achieve consistent removal function models, Effect of improving long-term stability and maintaining temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

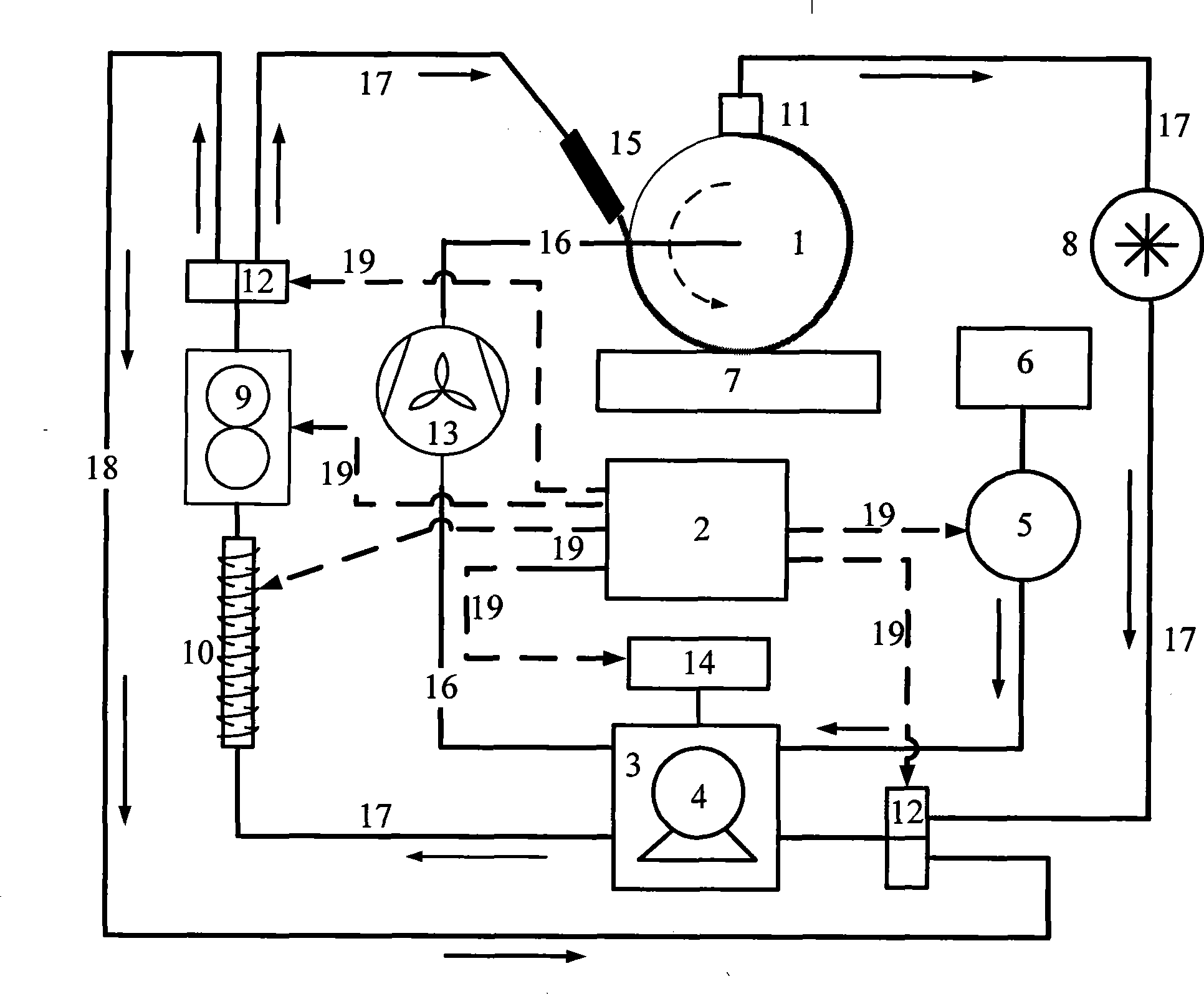

[0046] like figure 1 As shown, a magneto-rheological polishing liquid circulation device of the present invention that can stabilize the performance of the polishing liquid for a long time includes a liquid mixing tank 3 connected to each other through pipelines, a power pump 4, an electromagnetic flowmeter 9, a nozzle 15, and a recovery device 11. Recovery pump 8, cooling machine 13, water tank 6 and computer 2, power pump 4 is connected to liquid mixing tank 3, liquid mixing tank 3 is connected to water tank 6 through metering pump 5, cooling machine 13 is mixed with liquid through cooling pipeline 16 The tanks 3 are connected; the liquid mixing tank 3, the electromagnetic flowmeter 9, the nozzle 15, the recovery device 11 and the recovery pump 8 which are sequentially connected through the polishing circulation pipeline 17 form a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com