Coalface straightness control method

A coal mining face and control method technology, applied to mining equipment, earthwork drilling, mine roof support, etc., can solve the problems of lower production efficiency, uneven movement of scraper conveyors, etc., and achieve simple structure, low cost, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

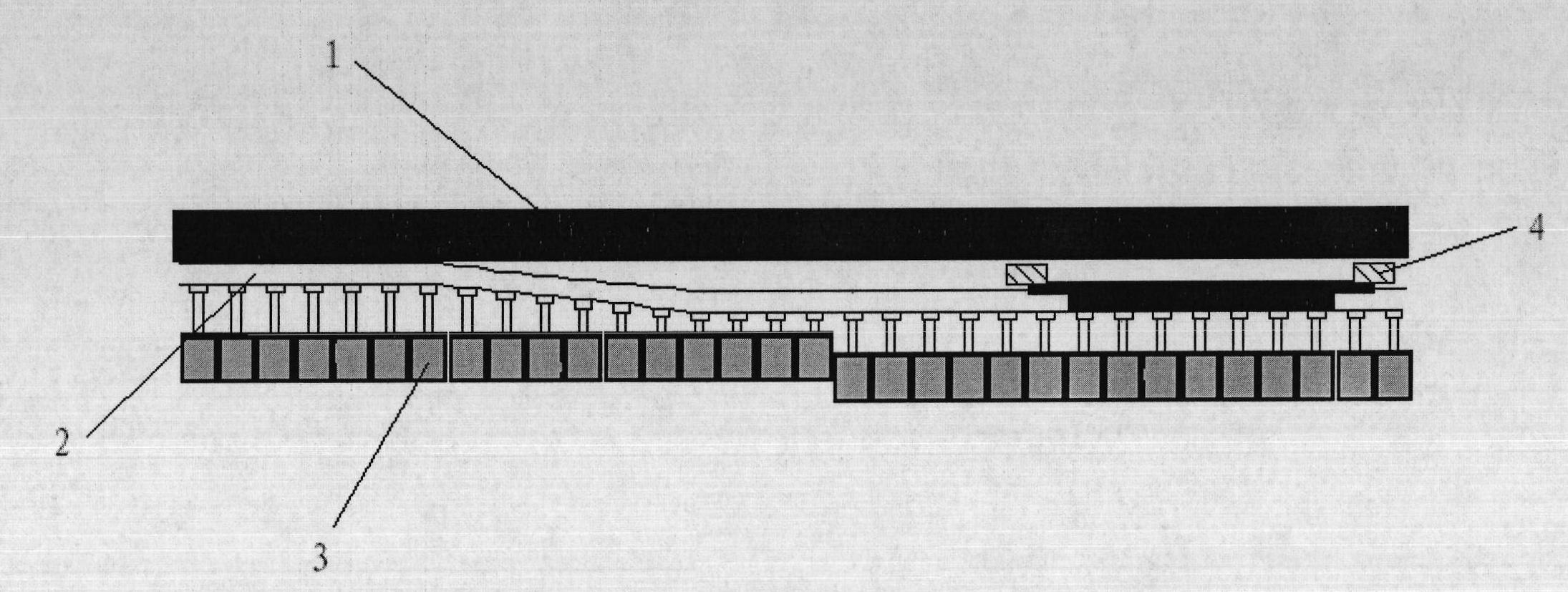

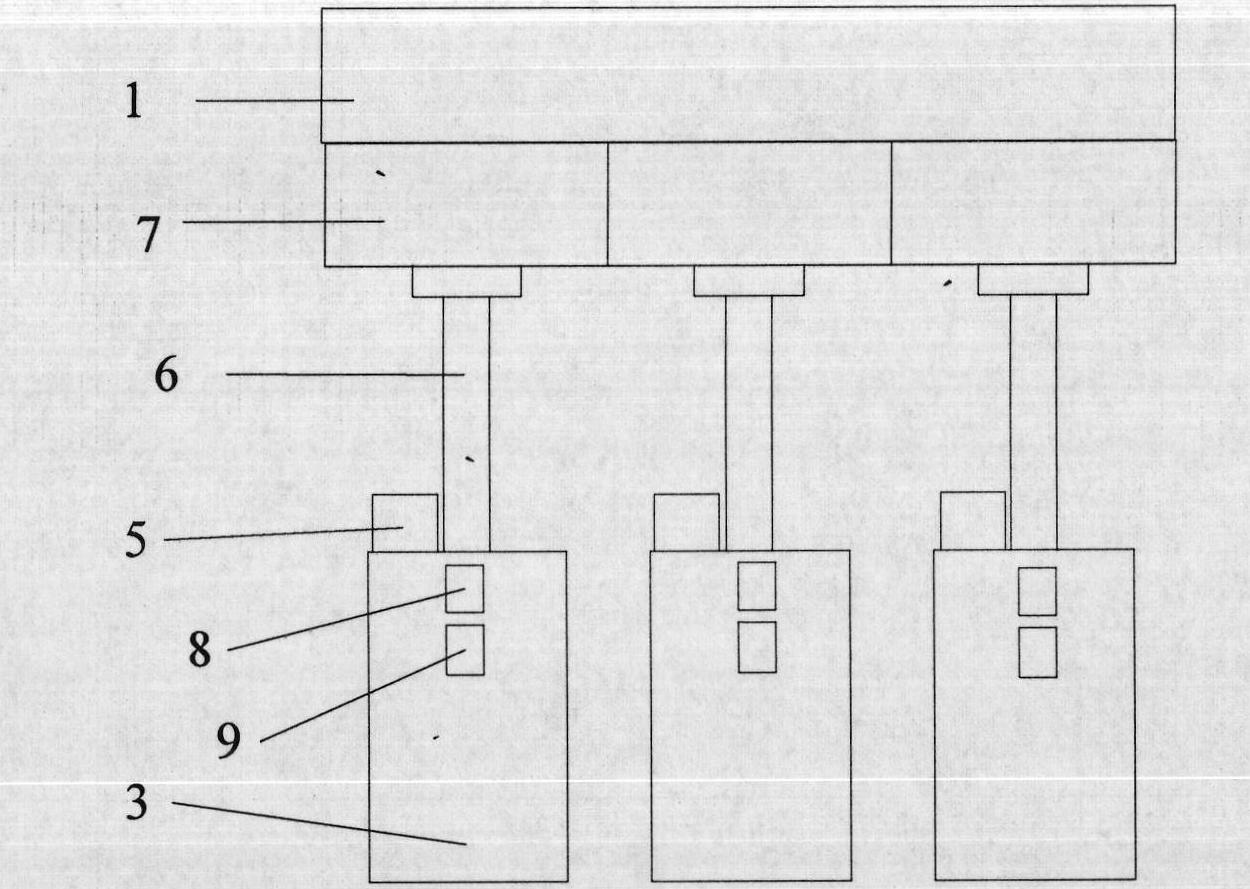

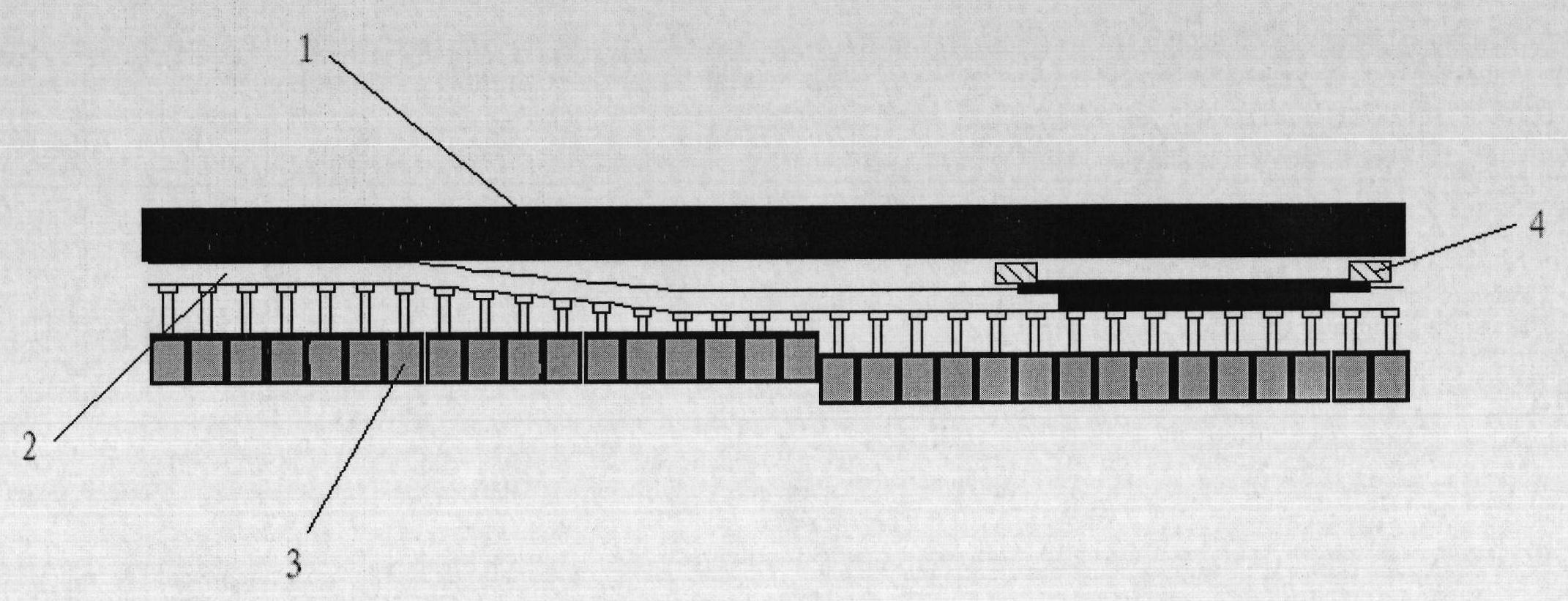

[0020] A preferred embodiment of the method for controlling the straightness of the coal mining face according to the present invention. In the working process, the coal mining face is basically a straight line, so its related equipment should also maintain a certain straightness. The straightness of the coal mining face in the present invention includes the straight lines of multiple hydraulic supports in the working face. And the straightness of its scraper conveyor. In the straightness control method of the coal mining face of the present invention, the straightness control device of the coal mining face includes a hydraulic support, a scraper conveyor, a distance meter, an angle sensor and a support controller. The scraper conveyor is usually arranged close to the coal mining face, and the shearer runs on it. It consists of multiple chutes. A group of multiple hydraulic supports arranged in sequence are provided on one side of the scraper conveyor to support coal mining. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com