Method for processing outer circle of cylindrical part based on upper plate eccentric pressurizing

A processing method, cylindrical technology, applied in the direction of metal processing equipment, work carrier, manufacturing tools, etc., can solve the problems of low precision and poor consistency, achieve geometric accuracy and dimensional accuracy, low surface roughness, and improve material removal rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

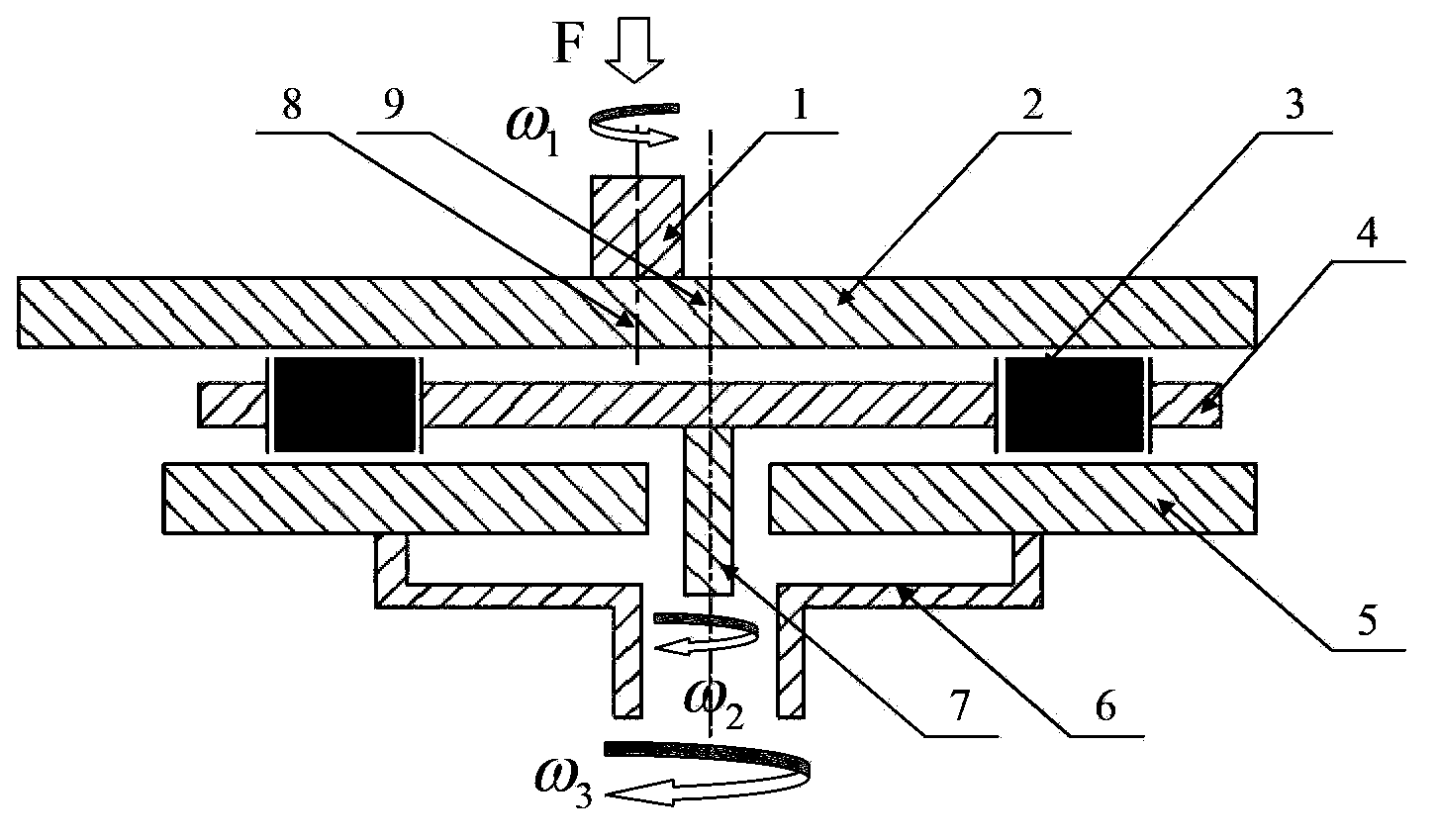

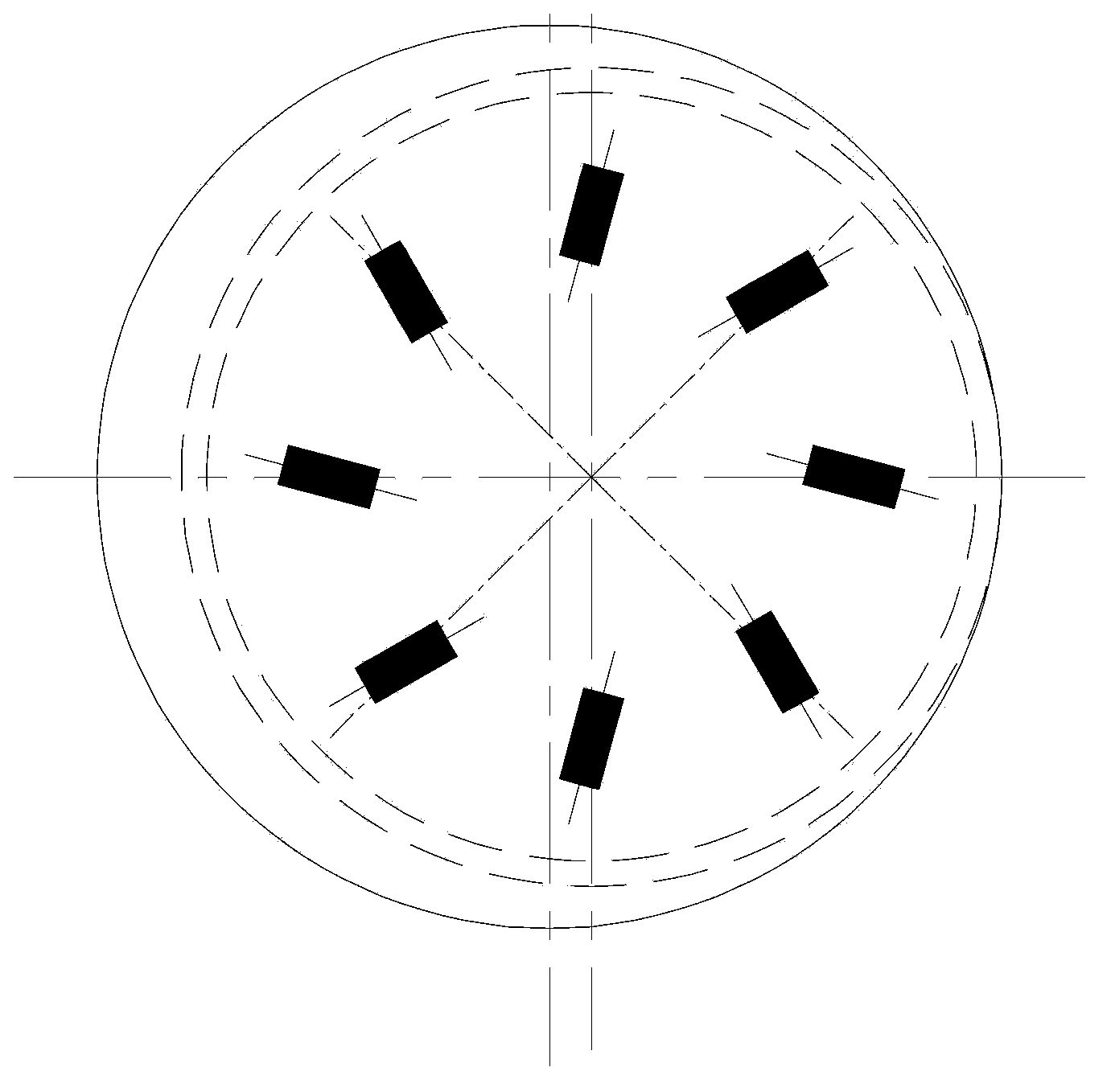

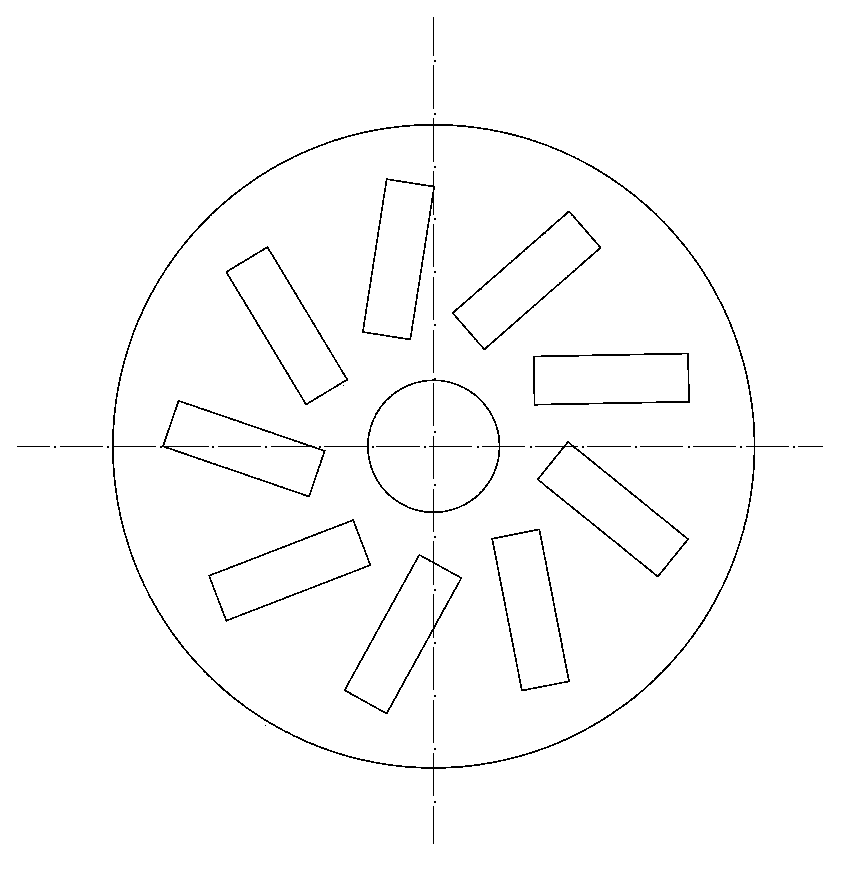

[0019] refer to Figure 1 ~ Figure 4 , a method of machining the outer circle of cylindrical parts based on the eccentric pressure of the upper disc, the processing device for realizing the processing method includes an upper grinding disc 2, a cage 4 and a lower grinding disc 5, and the upper grinding disc 2 is located in the lower grinding disc On the disc 5, the cage 4 is located between the upper grinding disc 2 and the lower grinding disc 5, the rotating shaft of the retaining frame 4 and the rotating shaft of the lower grinding disc 5 are arranged coaxially, and the rotating shaft of the upper grinding disc 5 and the lower grinding disc 5 are arranged coaxially. There is a definite offset in the rotating shaft of the cage 4;

[0020] The processing method includes the following process: the cylindrical part 3 to be processed is placed on the station of the cage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com