Attitude control system and method based on wireless three-dimensional gyroscope technology for scraper conveyer

A scraper conveyor and attitude control technology, which is applied in the direction of conveyor control devices, transportation and packaging, and conveyor objects, can solve the problems of reduced production efficiency, error accumulation, uneven movement of scraper conveyors, etc., to improve production The effect of improving efficiency, increasing service life, and improving coal cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

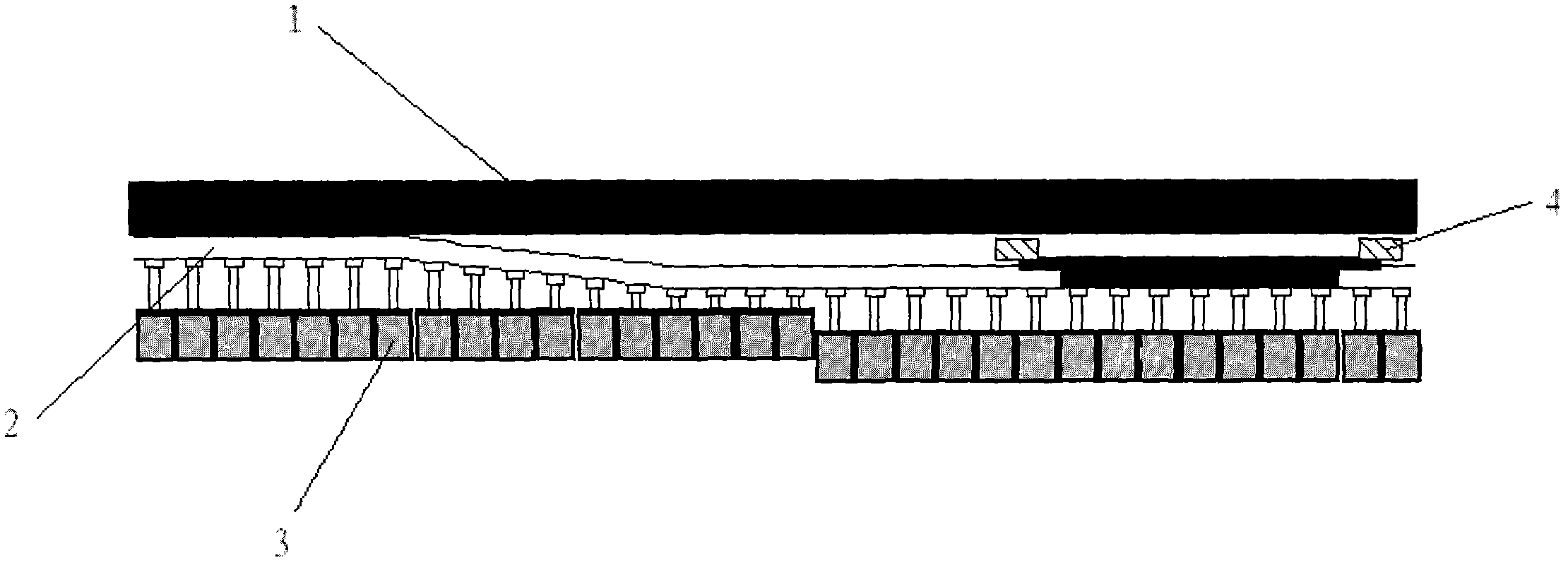

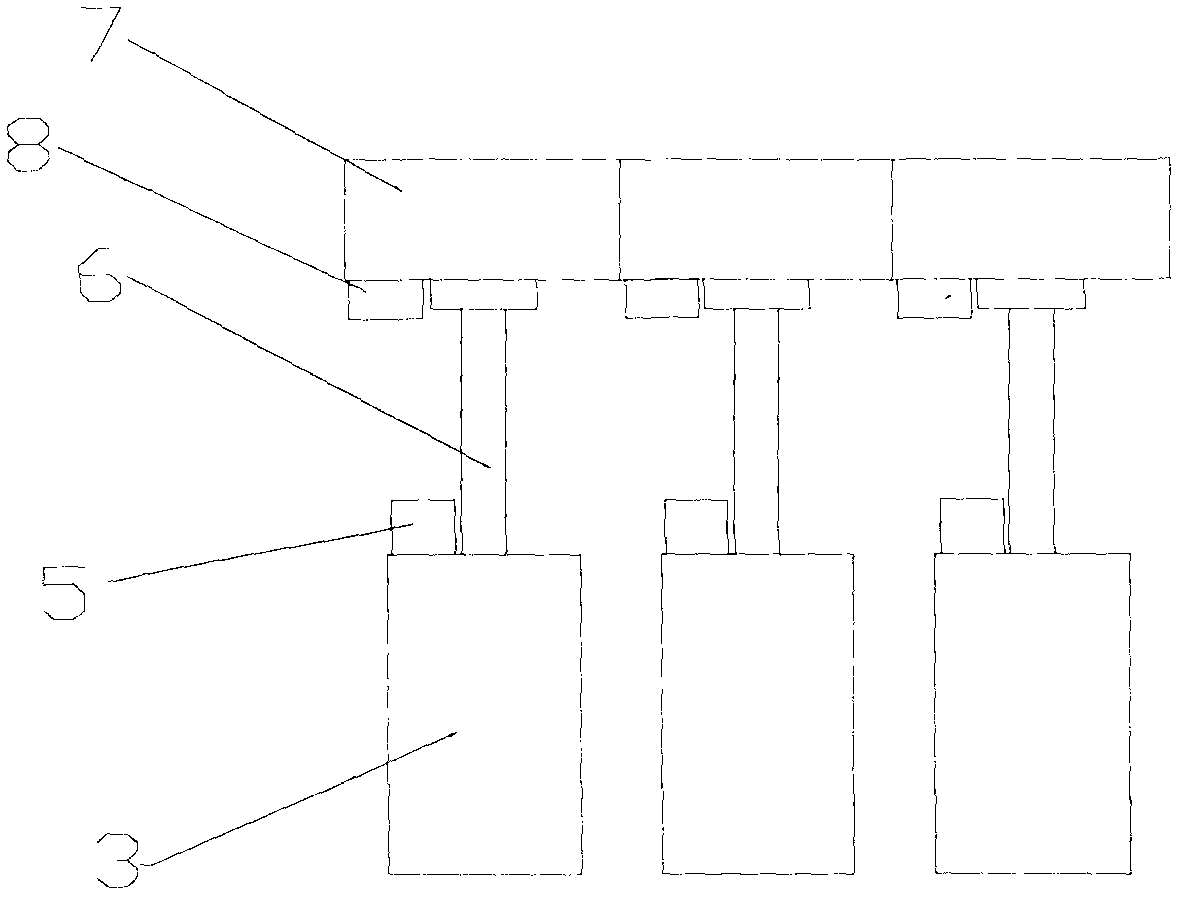

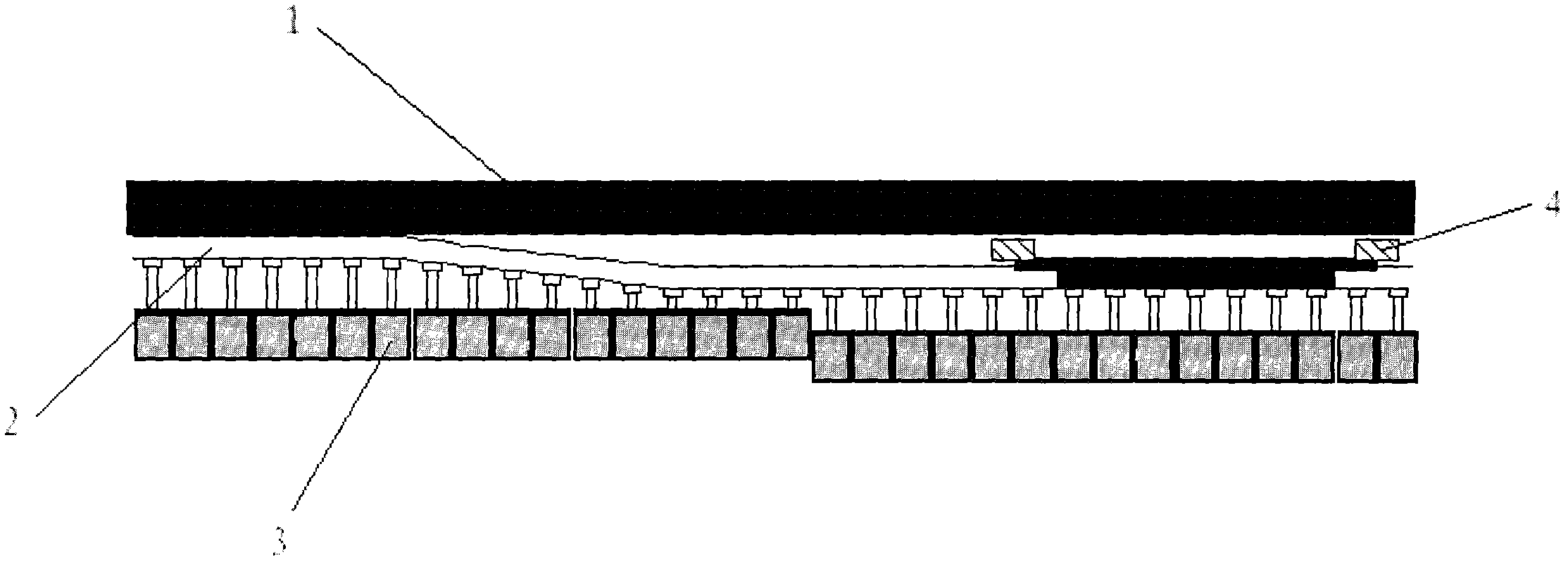

[0028] See attached Figure 1-2 , a scraper conveyor attitude control system based on wireless three-dimensional gyroscope technology, including a wireless three-dimensional gyroscope, a hydraulic support, a support controller and a trough monitoring host (not shown). The scraper conveyor is usually arranged close to the coal mining face, and the coal shearer runs on it. A group of sequentially arranged hydraulic supports are arranged on one side of the scraper conveyor to support the roof of the coal mining face, and with the coal mining The forward advancement of the working face pushes the scraper conveyor to move towards the coal mining face by pushing the jack. The scraper conveyor is composed of multiple interconnected chutes, and there is a limited deflection between each chute. The main detection component, the wireless 3D gyroscope, is installed on the chute of the scraper conveyor to detect the running posture of the scraper conveyor. The wireless 3D gyroscope The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com