Low yield ratio high tension steel plate and its producing method

A technology with a low yield ratio and a manufacturing method, applied in the field of high-tensile steel plates, can solve the problems of reducing the acoustic anisotropy, deteriorating the toughness of the base metal and HAZ toughness, and deteriorating the toughness of the base metal, etc., to simplify the defect detection work. , The effect of reducing acoustic anisotropy and excellent toughness of the base material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

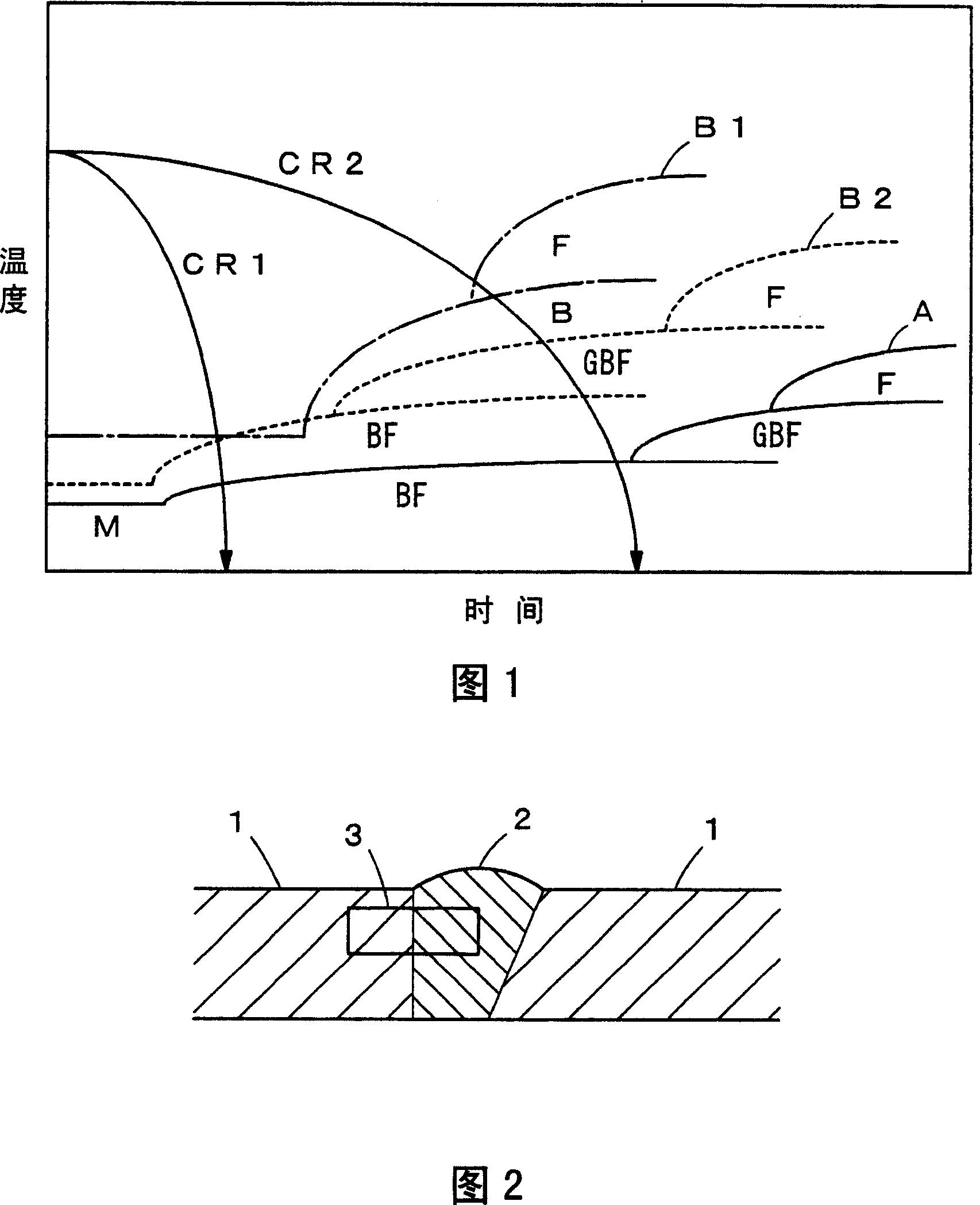

[0040] The main point of the composition of the steel plate of the present invention is to limit the amount of Nb, V, and Mo (DL≤2.80) that have a bad influence on the toughness of the HAZ and the toughness of the base material on the basis of limiting the C content to extremely low, and actively Mn, Ni, and Cu, which improve hardenability, are added. First, the characteristics of the structure formed by hot rolling of the steel material of the steel sheet according to the present invention will be described with reference to the CCT diagram.

[0041] Fig. 1 shows CCT diagrams of the extremely low C-based steel (A) to which Mn, Ni, and Cu are actively added in the present invention, and the existing high-C-based steel (B1) and low-C-based steel (B2). In the figure, BF is carbon-free bainite, GBF is granular carbon-free bainite, M is martensite, B is bainite, and F is ferrite.

[0042] It can be seen from the same figure that for the steel sheet (A) of the present invention, regard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com