Dendritic polyester, method for producing the same, and thermoplastic resin composition

A technology of dendritic polyester and thermoplastic resin, which is applied in the field of dendritic polyester, can solve problems such as inability to obtain performance and insufficient thermal stability, and achieve improved thin-wall fluidity, excellent shear response, and anisotropy small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

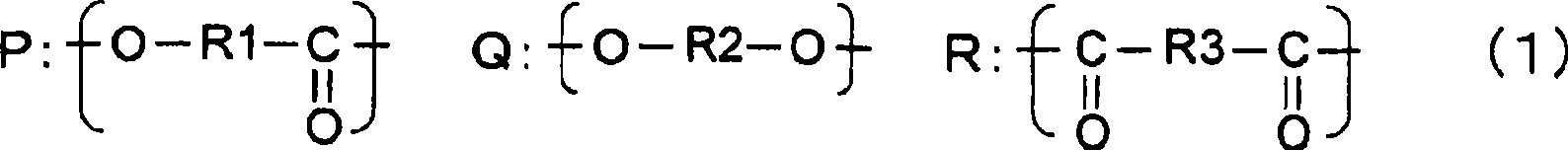

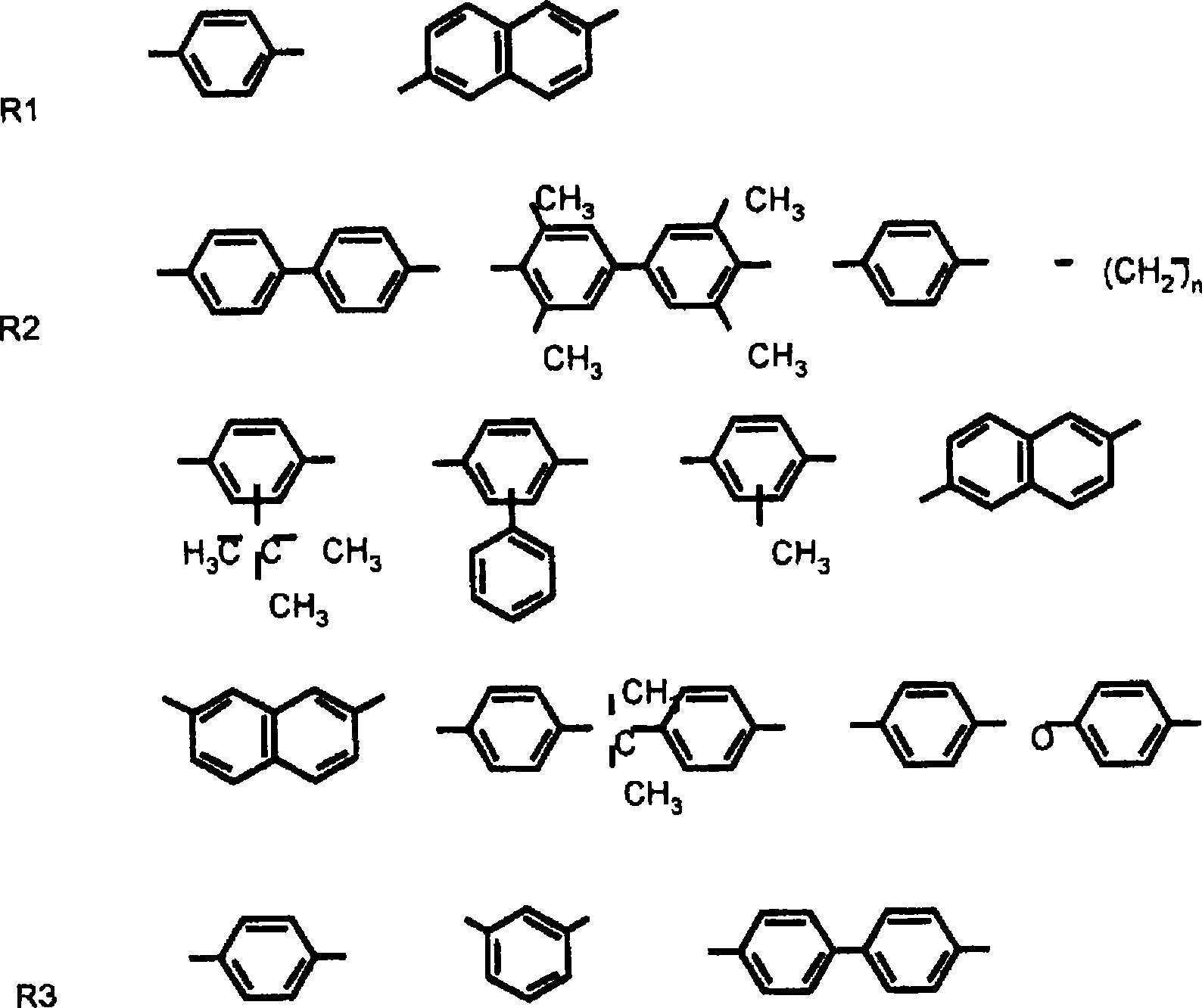

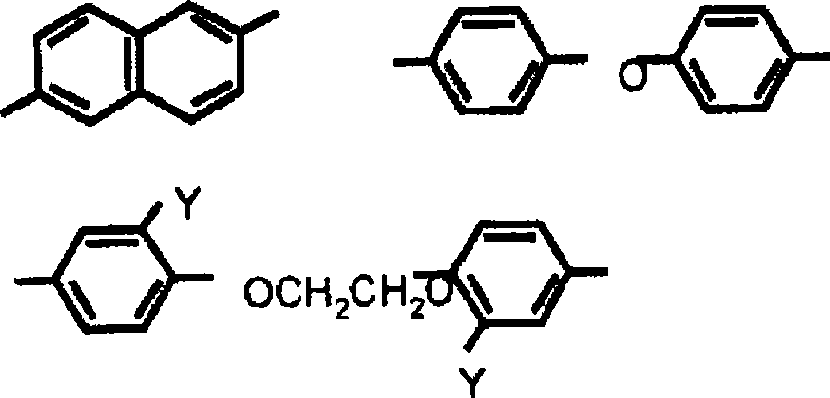

Method used

Image

Examples

Embodiment 1

[0152] Add 66.3g (0.48 mol) of p-hydroxybenzoic acid, 8.38g (0.045 mol) of 4,4'-dihydroxybiphenyl, 7.48g (0.045 mol) of terephthalic acid moles), 14.41 g (0.075 moles) of polyethylene terephthalate with an intrinsic viscosity of about 0.6 dl / g, and 62.48 g (1.00 equivalents of the total phenolic hydroxyl groups) of acetic anhydride were stirred under a nitrogen atmosphere while stirring Reaction at 145°C for 2 hours. Then add trimesic acid 31.52g (0.15 moles), heat up to 260°C, stir for 3 hours, after 91% of the theoretical distilled amount of acetic acid is distilled, stop heating and stirring, and the contents are spit out into cold water.

[0153] The obtained dendritic polyester (A-1) is carried out nuclear magnetic resonance spectrum analysis, the result is relative to trimesic acid residue, the content p of p-oxybenzoate (p-dioxybenzoate) unit is 2.66, 4, The content q of the 4'-dioxybiphenyl unit and the ethylene oxide unit was 0.66, the content r of the terephthalate ...

Embodiment 2

[0168] The raw material monomers were changed to 58.01g (0.42 moles) of p-hydroxybenzoic acid, 23.46g (0.126 moles) of 4,4'-dihydroxybiphenyl, 5.95g (0.054 moles) of hydroquinone, and 19.44g (0.117 moles) of terephthalic acid moles), isophthalic acid (0.063 moles), acetic anhydride 79.63g (1.00 equivalents of phenolic hydroxyl group total) and trimellitic acid 31.52g (0.15 moles), except that, operate in the same way as in Example 1 to obtain Dendritic polyester. The obtained dendritic polyester was evaluated in the same manner as in Example 1. The results are shown in Table 1 and Table 2.

Embodiment 3

[0170] The raw material monomers were changed to p-hydroxybenzoic acid 58.01g (0.42 mol), 4,4'-dihydroxybiphenyl 65.36g (0.351 mol), hydroquinone 5.95g (0.054 mol), terephthalic acid 19.44g (0.117 moles), isophthalic acid (0.063 moles), acetic anhydride 83.61g (1.05 equivalents of the total phenolic hydroxyl group) and trimesic acid 31.52g (0.15 moles), except that, operate in the same way as in Example 1 to obtain Dendritic polyester. The obtained dendritic polyester was evaluated in the same manner as in Example 1. The results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com