New type of motor with high heat dissipation performance

A technology with high heat dissipation performance and high efficiency, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of abnormal motor operation, fans cannot guarantee heat dissipation efficiency, etc., and achieve the effect of increasing the outer surface area, good heat dissipation effect, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

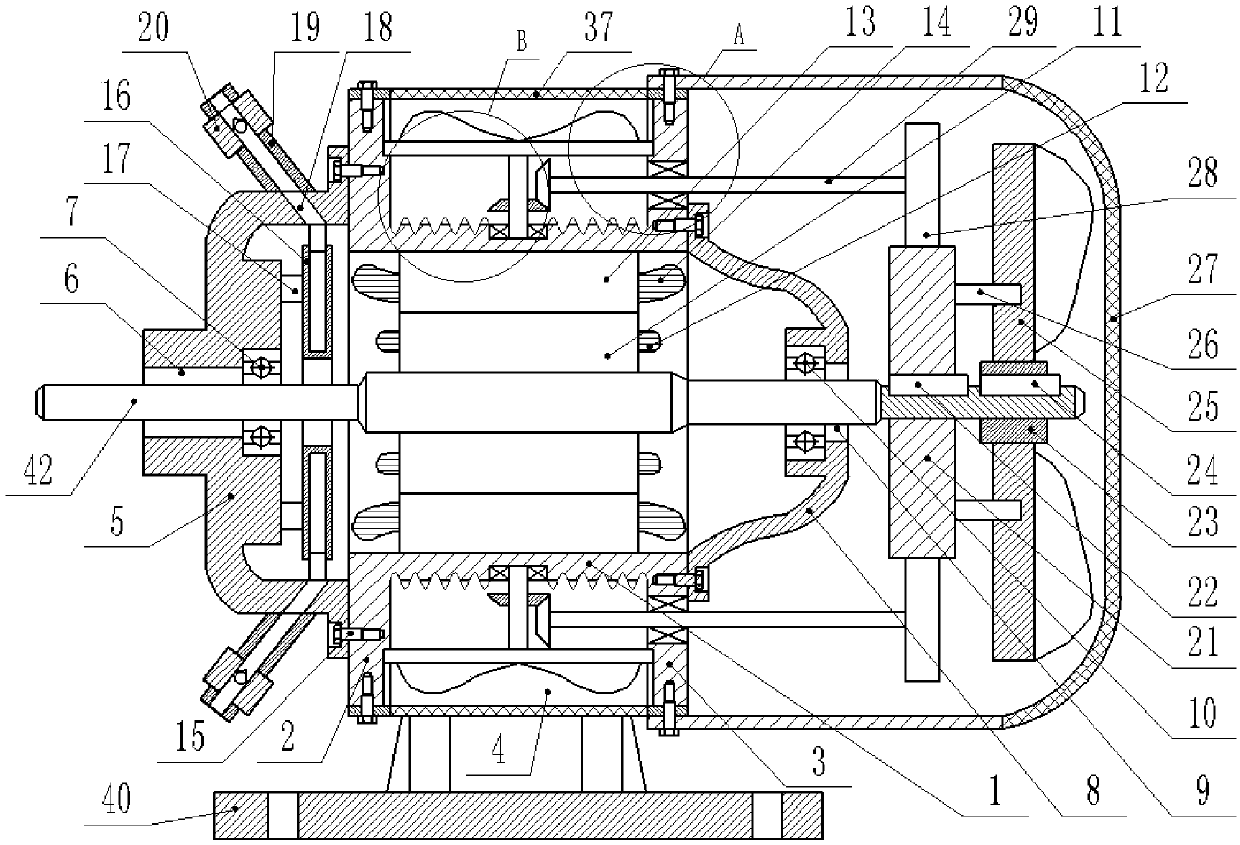

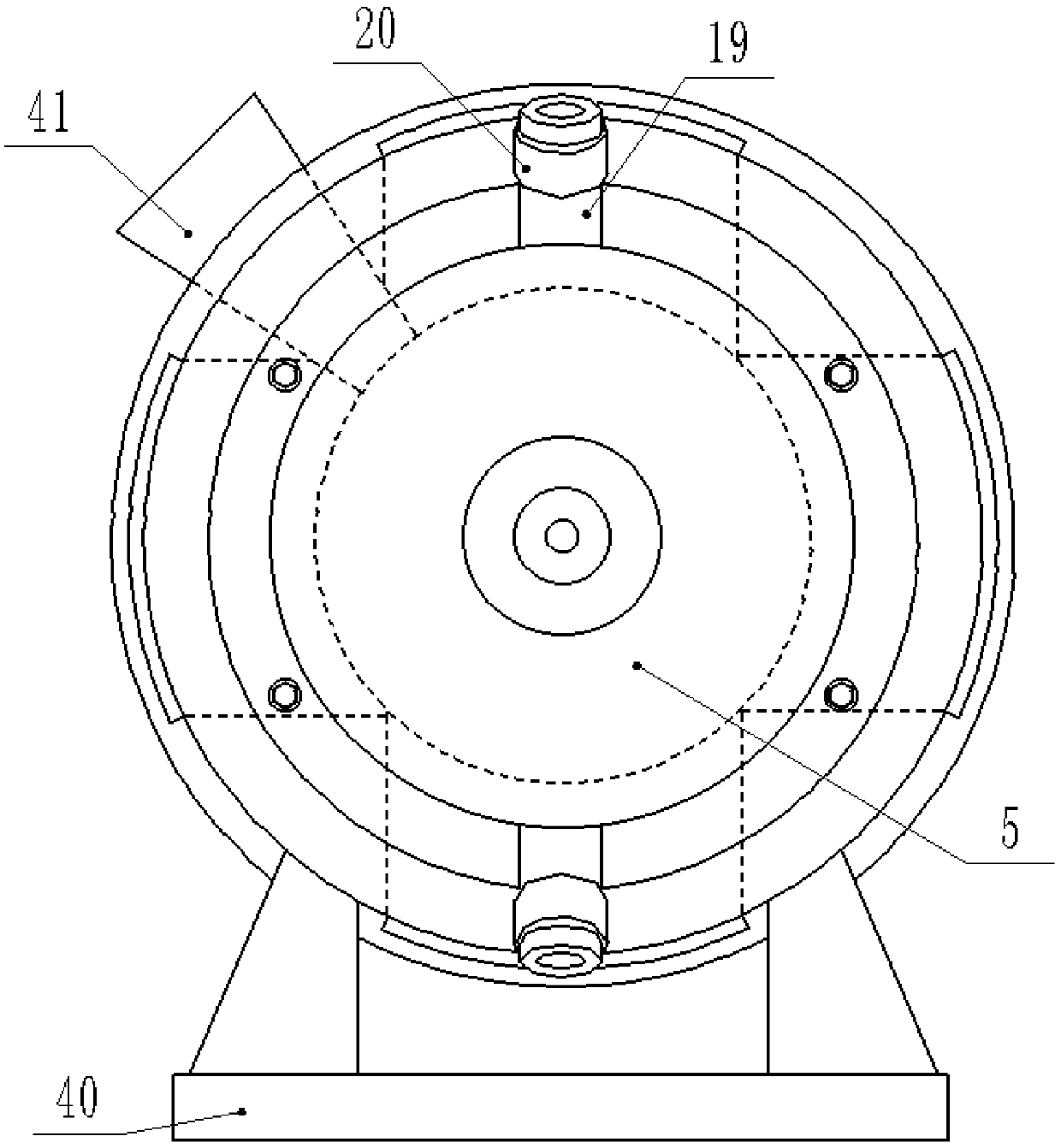

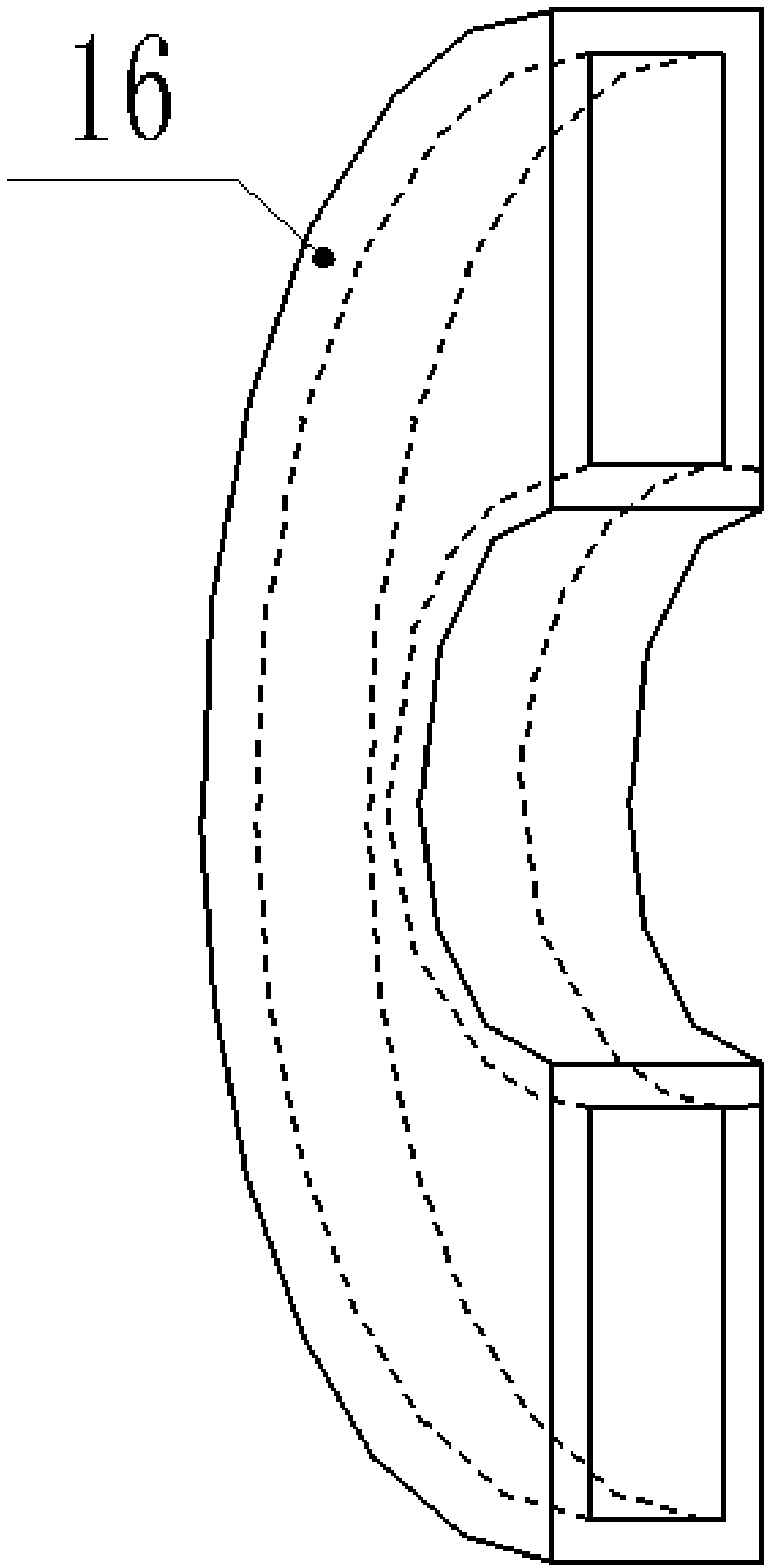

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a new type of motor with high-efficiency heat dissipation includes a casing 1, a front end cover 5, a rear end cover 8 and several bolts 15, and left convex rings 2 integrally formed with the casing 1 are respectively provided at both ends. and the right convex ring 3, the front end cover 5 is fixed with the left convex ring 2 by several bolts 15, the rear end cover 8 is fixed with the right convex ring 3 by several bolts 15, and the front end cover 5 is provided with a front cover through hole 6, the rear end cover 8 is provided with a rear end cover through hole 9, the housing 1 is provided with a main shaft 42, one end of the main shaft 42 passes through the front end cover through hole 6, and passes through the front bearing 7 and the front end The cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com