Tenon engraving machine

A tenon engraving machine and engraving machine technology, applied in the field of engraving machines, to achieve the effect of reducing labor production costs, reducing costs, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

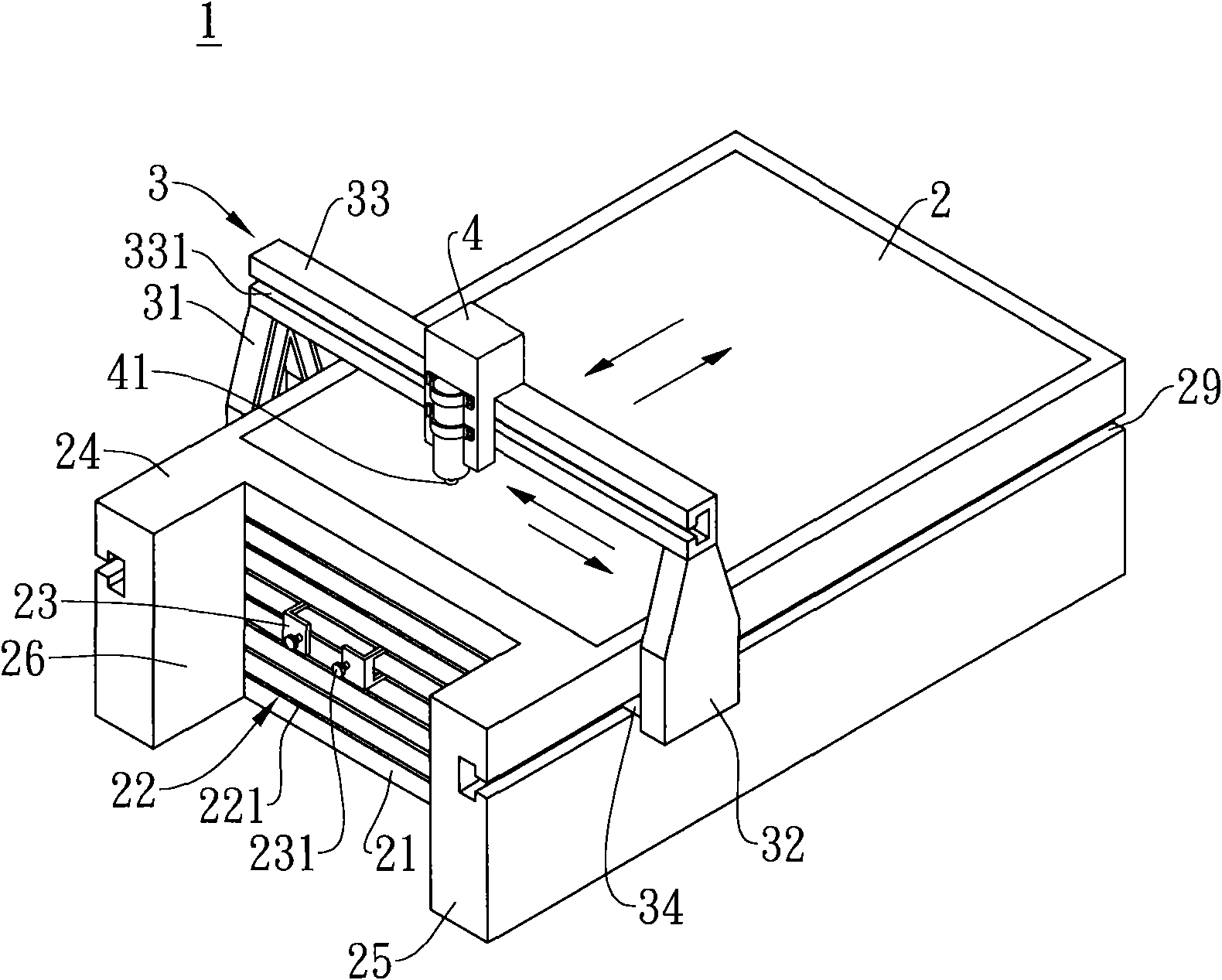

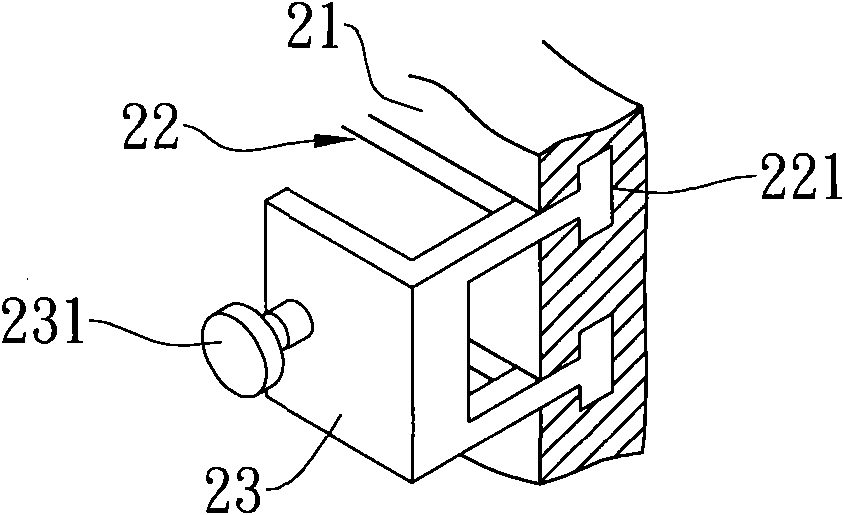

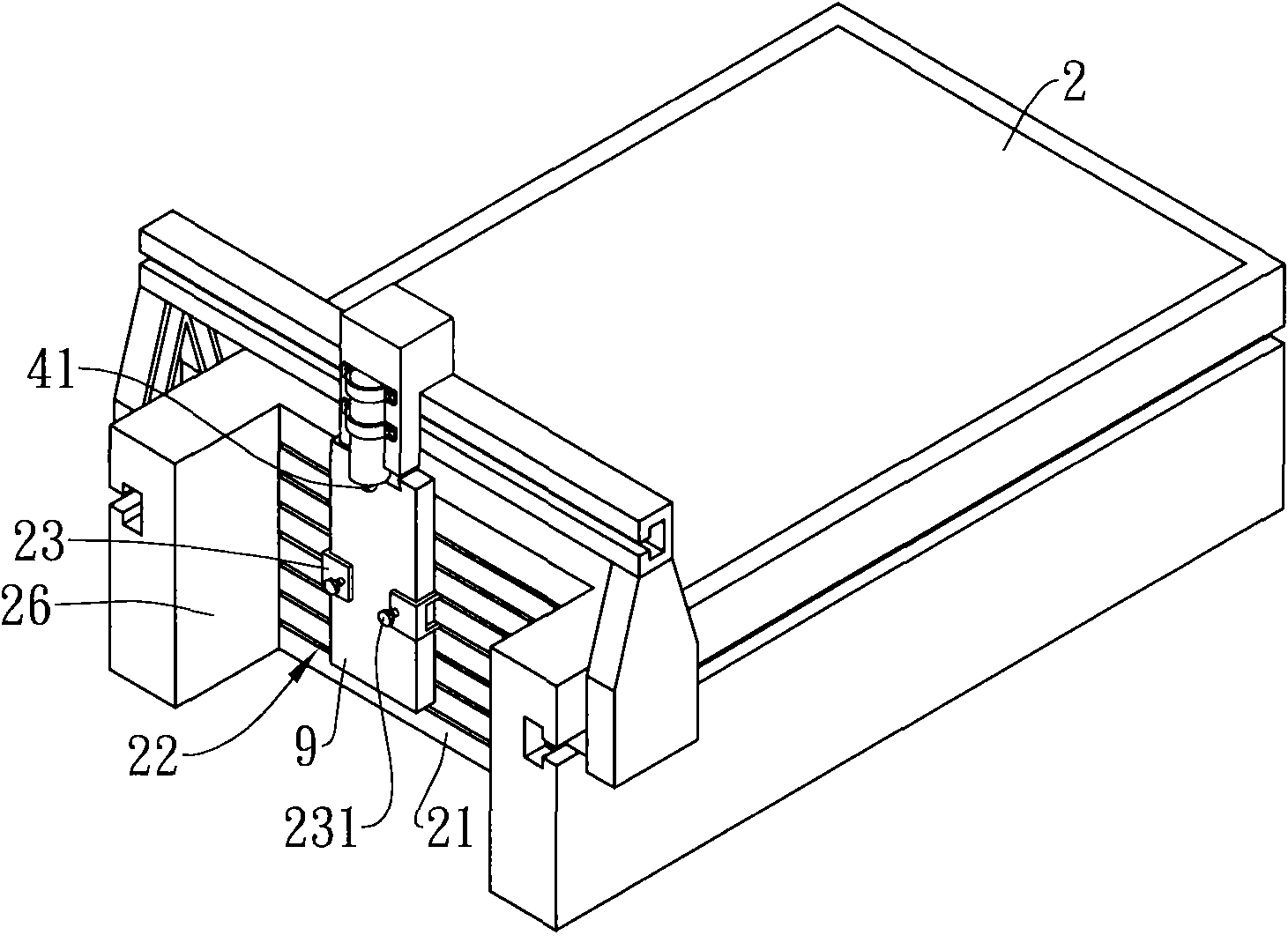

[0024] see figure 1 , 2 As shown, it is the first embodiment of the tenon engraving machine 1 of the present invention, which includes a machine table 2 , a hanger 3 and a knife seat 4 . The machine platform 2 is roughly cuboid, and its left and right sides are respectively provided with a long guide rail 29; Composed of rods 33, a roller 34 is respectively arranged on the relative inner side of the left bracket 31 and the right bracket 32, and the two rollers 34 are respectively positioned in the guide rails 29 on the left and right sides of the machine platform 2, so that the hanger 3 can move forward and backward in parallel with respect to the machine table 2; and a cutting tool 41 for cutting is provided below the tool seat 4, and the tool seat 4 is connected to the bridge rod 33 of the hanger 3, G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com