Novel assembling type precast concrete urban comprehensive pipe gallery and construction method thereof

A technology of prefabricated concrete and comprehensive pipe gallery, which is applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of large size of comprehensive pipe gallery, poor force transmission effect, and increased water permeability probability, etc., to achieve high construction efficiency, Good structural stability, the effect of improving structural integrity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

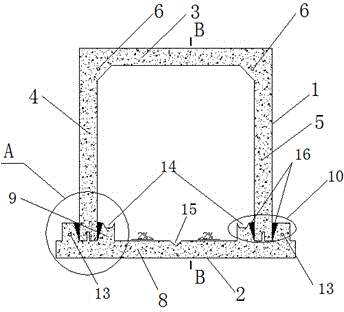

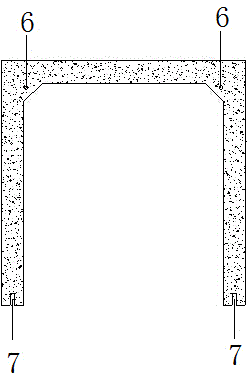

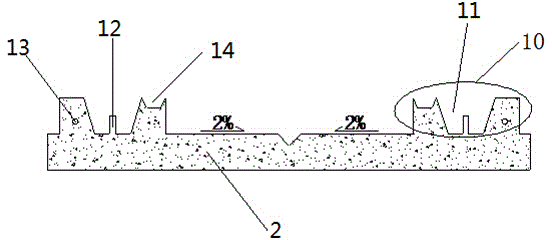

[0032] see Figure 1-8 , a new type of prefabricated concrete urban comprehensive pipe gallery, including a plurality of inverted U-shaped cover plates 1 and a plurality of base plates 2, the length of the base plate 2 is three times the length of the inverted U-shaped cover plate 1, each Three inverted U-shaped cover plates 1 can be installed on the base plate 2 to improve the structural integrity and stability of the comprehensive pipe gallery, thereby reducing the influence of local uneven settlement of the foundation, and at the same time reducing the probability of water penetration of the base plate 2. It also effectively improves the construction efficiency. The inverted U-shaped cover plate 1 includes a horizontal plate 3, a left vertical plate 4 and a right vertical plate 5, and the left vertical plate 4 and the right vertical plate 5 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com