Three-strand splitting rolling method for ribbed steel bar

A technology of split rolling and ribbed steel bars, applied in the direction of metal rolling, metal rolling, rolls, etc., can solve the problems of poor neutrality of pre-cut holes, finished product defects, uneven wear of rolling grooves, etc., and achieve cross-sectional area error. Small, good neutrality, uniform wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

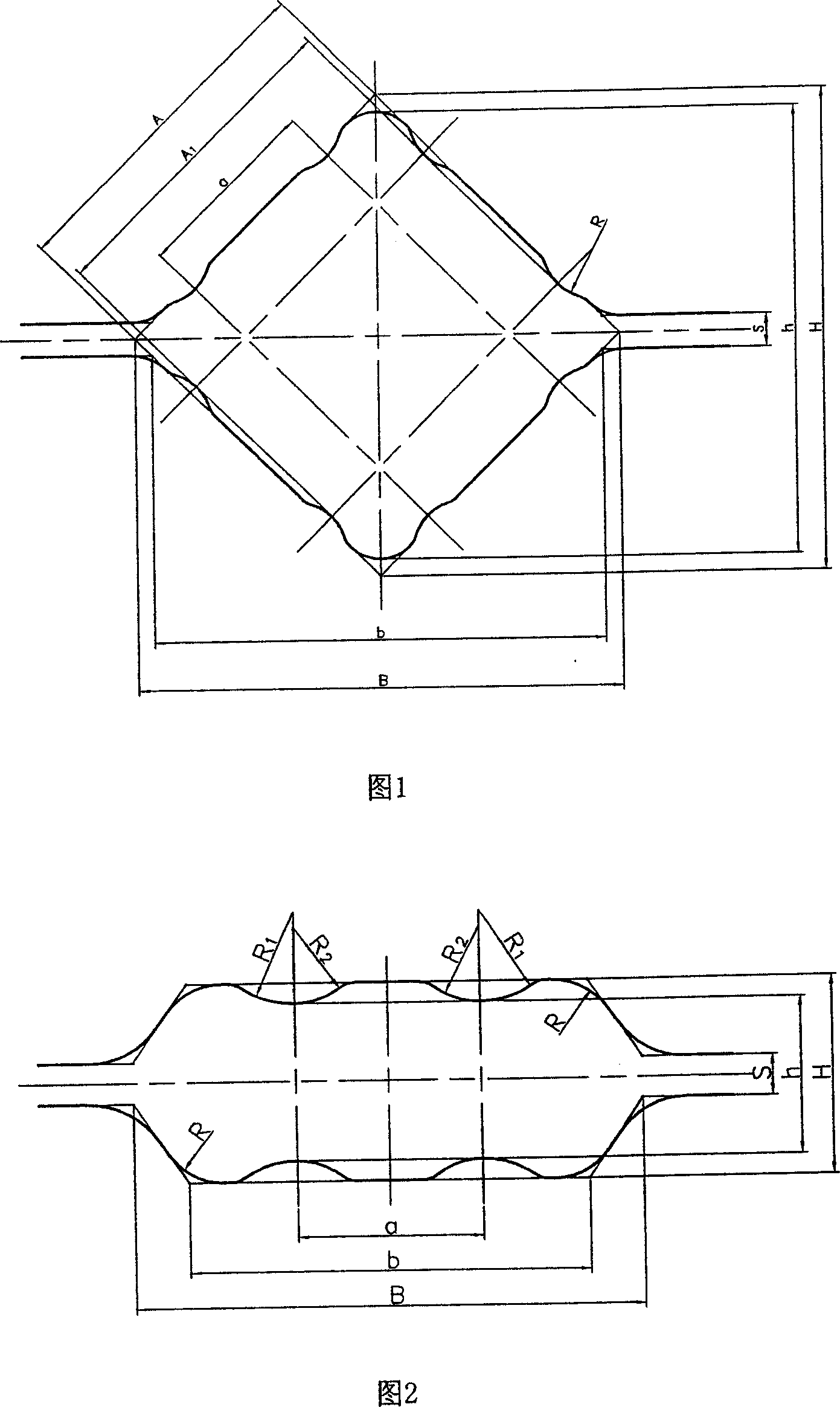

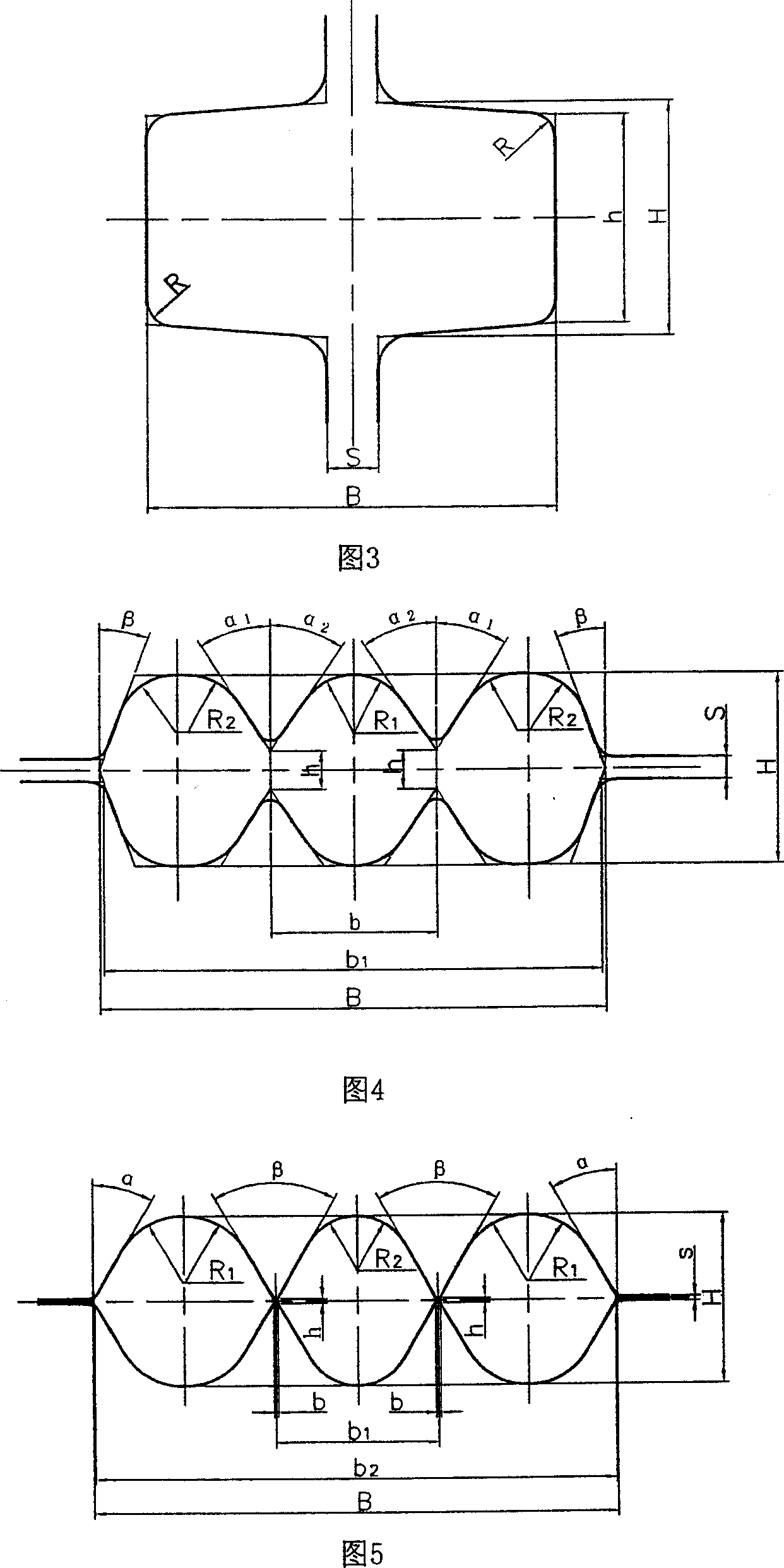

[0021] See Figure 1-5, a three-line split production line for rolling φ14mm ribbed steel bars. There are 17 rolling mills in the whole line, which are divided into 3 units of rough rolling, intermediate rolling and finishing rolling. Among them, the rough rolling unit has 5 rolling mills, and the rolling mills are numbered 1V, 2H, 3V, 4H, 5V; the middle rolling group has 6 rolling mills, and the rolling mill numbers are 6H, 7V, 8H, 9V, 10H, 11V; the finishing rolling group has 6 rolling mills, and the rolling mill numbers are 12H, 13H / V , 14H, 15H / V, 16H, 17H / V; V stands for vertical rolling mill, H stands for horizontal rolling mill, H / V stands for Keli-level conversion rolling mill. The rough rolling unit passes through 5 passes, and the pass pattern adopts the same pass system as that of single-line rolling or second-line slitting rolling; the middle rolling passes 4 passes, and the pass pattern of the first 3 passes adopts the same pass pattern as that of single-line rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com