Rack lamp, panel type lamp stamping machine and stamping technique thereof

A technology of stamping processing and lamps, which is applied in the field of metal stamping processing, can solve the problems of low adaptability and flexibility, high total cost, and poor quality controllability, so as to increase flexibility and adaptability, improve stamping processing efficiency, The effect of simple equipment manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

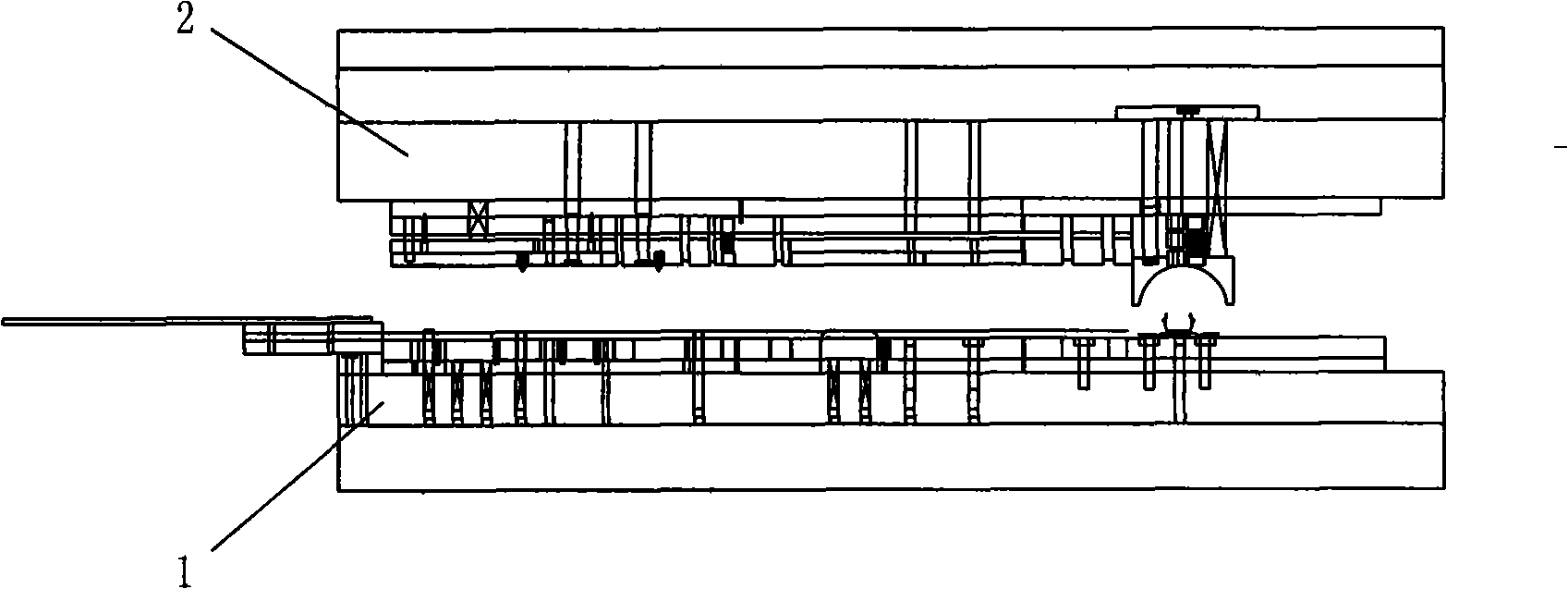

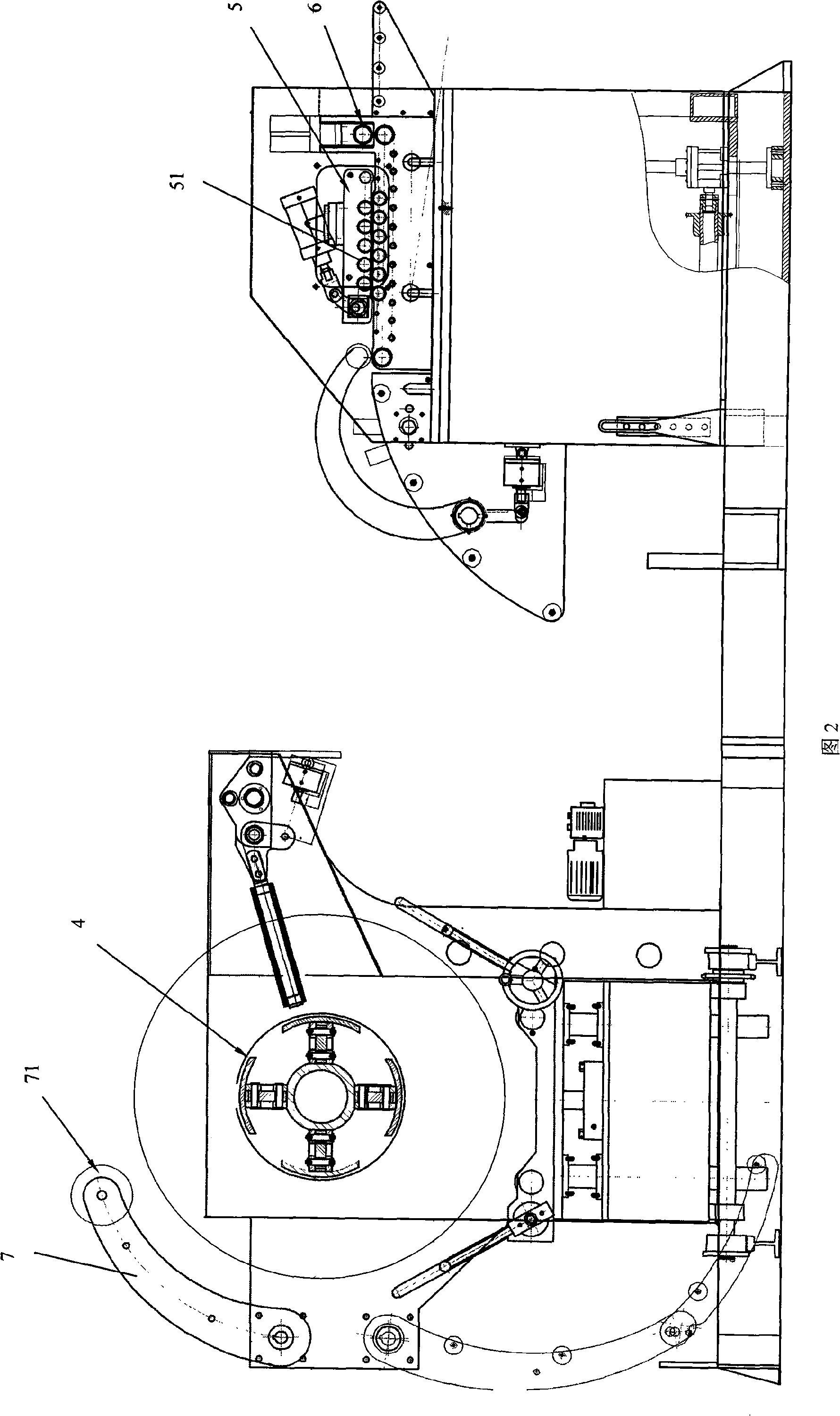

[0029] as attached figure 1 As shown in ~2, the machine tool disclosed in this embodiment is mainly used for stamping bracket lamps and lamp panel lamps. The machine tool includes a feeding servo mechanism for automatically supplying ingredients and a stamping die 3 for stamping blanks.

[0030] The feeding servo mechanism includes a material rack 4 for fixing the coil material, and a straightening table 5 for correcting and leveling the blank is arranged between the material rack 4 and the stamping die 3, and a feeder for pulling the blank into the stamping die 3 is arranged behind the straightening table 5 scroll wheel6. The material rack 4 is also provided with a pressing arm 7, and the end of the pressing arm is provided with a pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com