A method for processing straight-grained wood using laser cutting

A laser cutting and straight line technology, applied in the direction of charcoal burning/combustion, etc., can solve the problems of cutting capacity and cutting efficiency that cannot meet the actual production, limit the promotion and application of lasers, and expensive service costs, so as to reduce industrial accidents and high utilization rate , the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

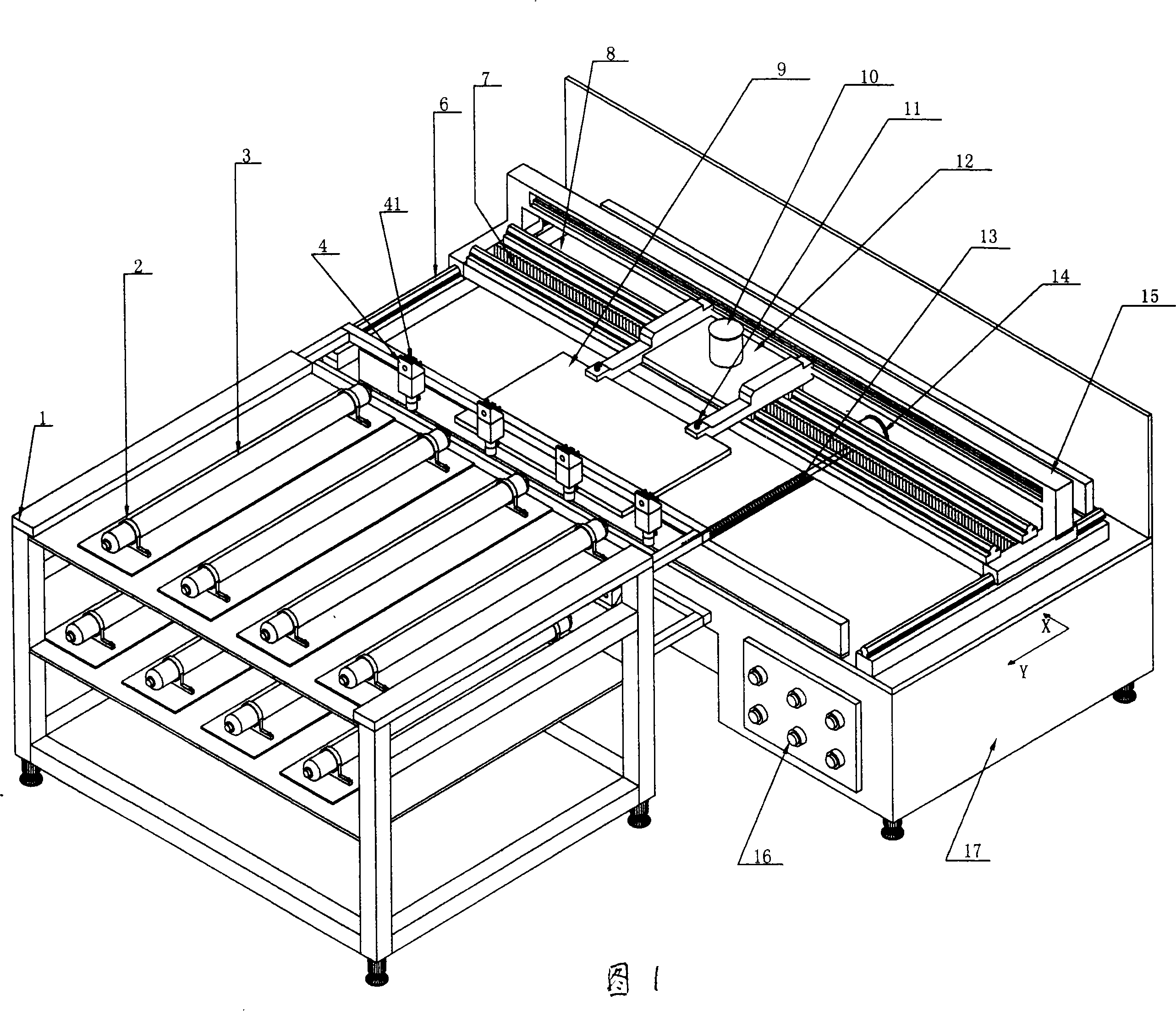

[0017] Referring to Fig. 1, this embodiment includes two parts: a laser cutting mechanism and an XY axis feeding mechanism.

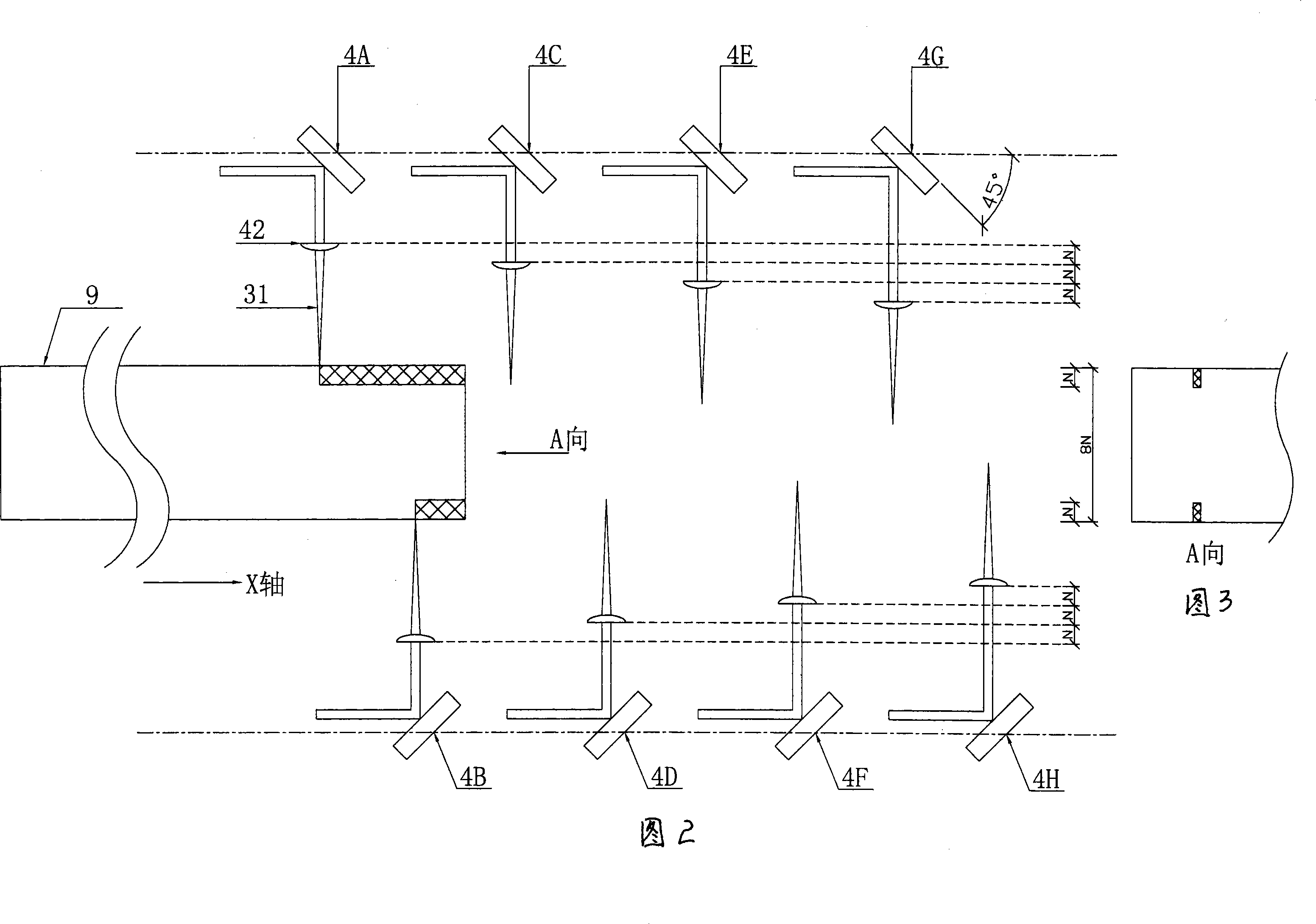

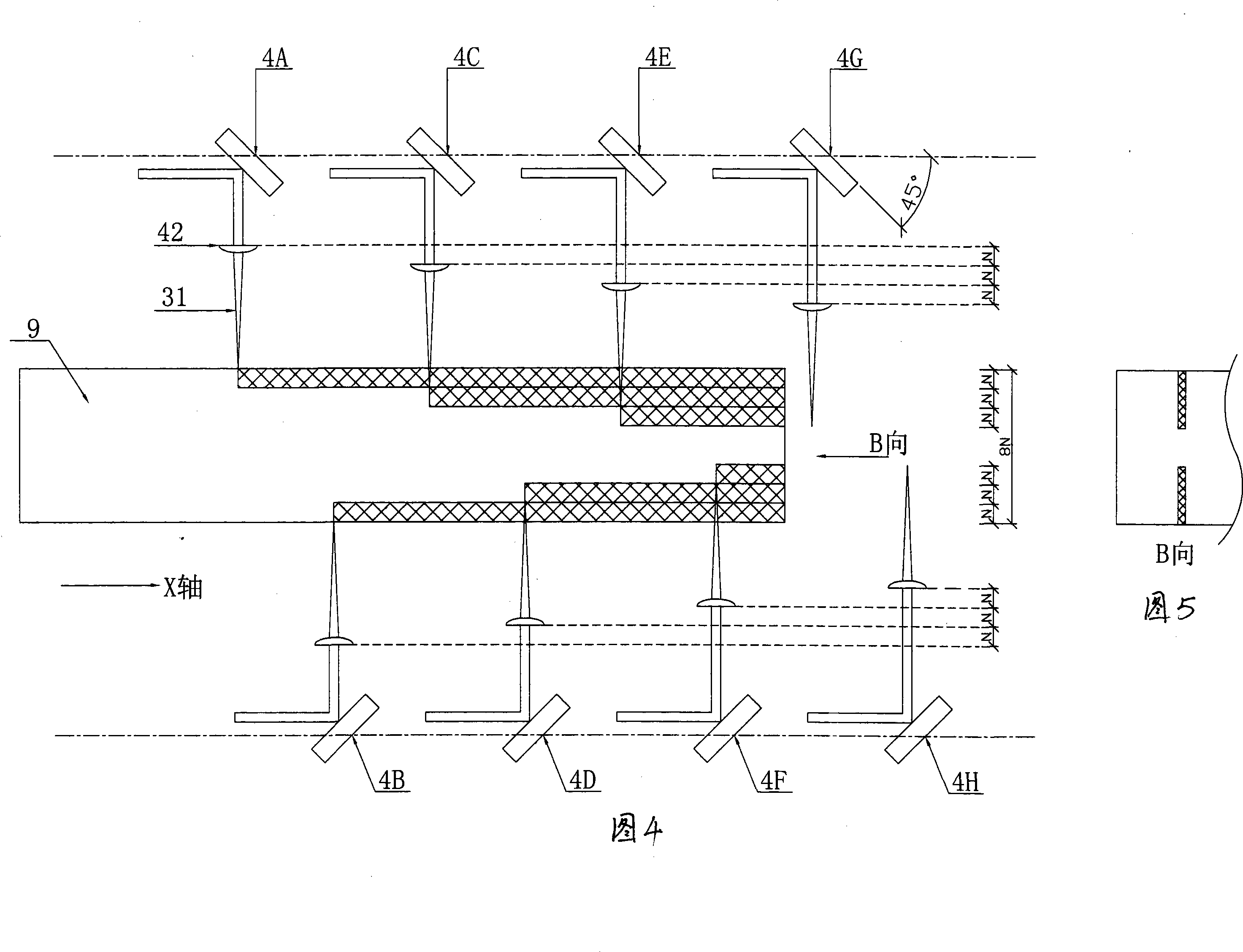

[0018] The laser cutting mechanism is the core part of this patent. What the laser generator 3 adopts is a domestic 60-watt laser generator, and the supporting laser power supply and cooling system all adopt domestic accessories, which is a conventional technology. The laser cutting mechanism of this embodiment includes eight groups of laser generators 3 with the same power of 60 watts, eight laser heads 4 and their 45-degree reflectors 41 and focusing mirrors 42. The eight groups of laser generators 3 are mounted on the support 2 respectively. The support 2 is locked on the frame 1 by screws, and the laser head 4 of the laser generator 3 is fixed on the front of the frame 1, and is divided into two rows and symmetrically distributed above and below the workpiece 9 to be processed, with four rows on the upper and lower rows When the laser heads 4 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com