Plate type workpiece glue injection robot system and glue injection method thereof

A robotic system and glue-spraying technology, applied in coatings, devices that apply liquid to surfaces, etc., can solve problems such as uneven spraying of glue on the surface of sponges or boards, inability to maintain stable product quality, and impact on the health of workers. , to achieve the effect of saving glue, reasonable glue spraying trajectory, and saving glue amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

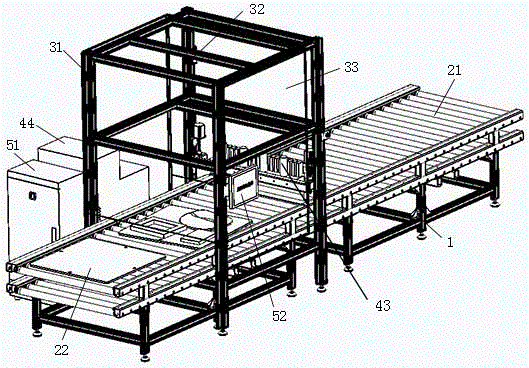

[0038] Such as figure 1 As shown, a plate type workpiece glue spraying robot system includes a number of glue spraying mechanisms connected end to end in sequence, each of the glue spraying mechanisms includes a frame 1, a transmission device arranged on the frame 1, a visual processing room, and a glue spraying mechanism. devices and controls. According to the needs of the production scale, only one glue spraying mechanism or multiple glue spraying mechanisms can be set.

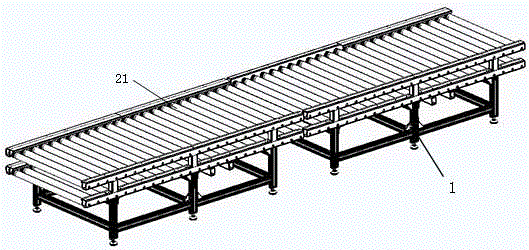

[0039] The transmission device includes several groups of linear plane transmission mechanisms 21 connected end to end in sequence and a tray 22 arranged on the upper surface of the linear plane transmission mechanisms 21 . The linear plane transmission mechanism 21 includes an upper layer transmission line and a lower layer tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com