Casting blank cutting positioning method and system

A billet and cutting device technology, applied in the field of iron and steel smelting, can solve the problems of low accuracy and high equipment maintenance costs, and achieve the effects of improving accuracy, reducing labor intensity of employees, and reducing industrial accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

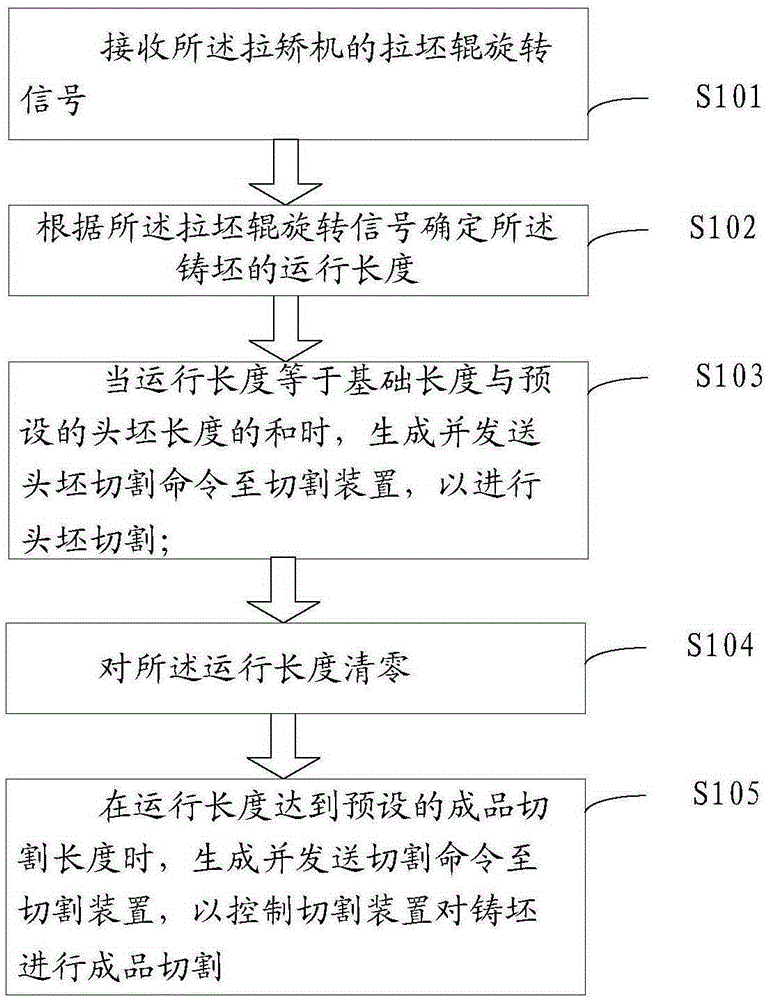

[0048] In this embodiment, a billet cutting and positioning method is provided, the method is applied in electronic equipment, the electronic equipment is connected with the cutting device, and the electronic equipment is connected with the tension leveler, please refer to figure 1 , figure 1 It is a flow chart of the method for cutting and positioning the slab in the embodiment of the present application, such as figure 1 As shown, the method includes:

[0049] Step S101, receiving the drawing roller rotation signal of the drawing and leveling machine;

[0050] Step S102, determining the running length of the cast slab according to the rotation signal of the casting roll;

[0051] Step S103, when the running length is equal to the sum of the base length and the preset length of the first billet, generate and send a first billet cutting command to the cutting device, so as to control the cutting device to cut the first billet on the casting strand ; Wherein, the base length...

Embodiment 2

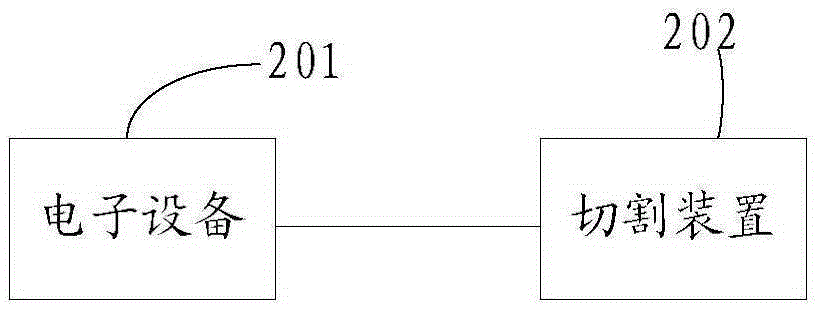

[0067] In this embodiment, a slab cutting positioning system is provided, please refer to figure 2 , figure 2 It is a structural schematic diagram of the cutting and positioning system of the billet in the embodiment of the present application, such as figure 2 As shown, the system includes:

[0068] An electronic device 201 and a cutting device 202 connected to the electronic device 201; wherein the electronic device 201 is connected to a tension leveler;

[0069] Wherein, the electronic device 201 is used for:

[0070] receiving the drawing roller rotation signal of the drawing and leveling machine;

[0071] determining the running length of the cast strand according to the rotation signal of the casting roll;

[0072] When the running length is equal to the sum of the base length and the preset length of the first billet, a first billet cutting command is generated and sent to the cutting device 202, so as to control the cutting device to cut the first billet; , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com