Turnover method for overweight block of ship

A ship and steel plate technology, which is applied to ship components, ship construction, ships, etc., can solve the problems of high risk factor of segmental overturning, and achieve the effects of reducing industrial accidents, broad market prospects, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] Now take the 500-ton section turning of a 300,000-ton oil tanker as an example; a method for overweight section turning of a ship includes the following steps:

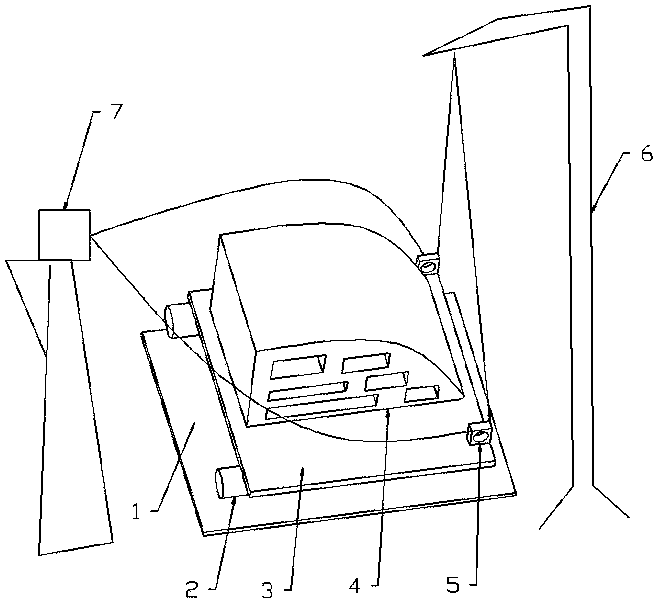

[0021] A. Clean up the steel plate floor 1 first, and lift the section 4 by a large gantry crane;

[0022] B. Lay the rubber plate 3 under the section 4, install two turbine propellers 2 on one side of the rubber plate 3, and install two lifting lugs 5 on the other side;

[0023] C. Slowly place the segment 4 on the rubber plate 3, wrap the segment 4 with a rubber cover, and the rubber cover and the rubber plate 3 are bonded together to form a sealing body, which prevents water from corroding the segment 4 and prevents the Secondary processing for scratches in subsection 4;

[0024] D. On the steel plate ground 1, surround the segment 4 with a steel plate to form a tank, and pour water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com