Overturning machine for household appliance

A technology of household appliances and turning machines, applied in manipulators, program-controlled manipulators, metal processing, etc., can solve the problems of reducing production efficiency, increasing production costs, time-consuming and laborious, etc., and achieve the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

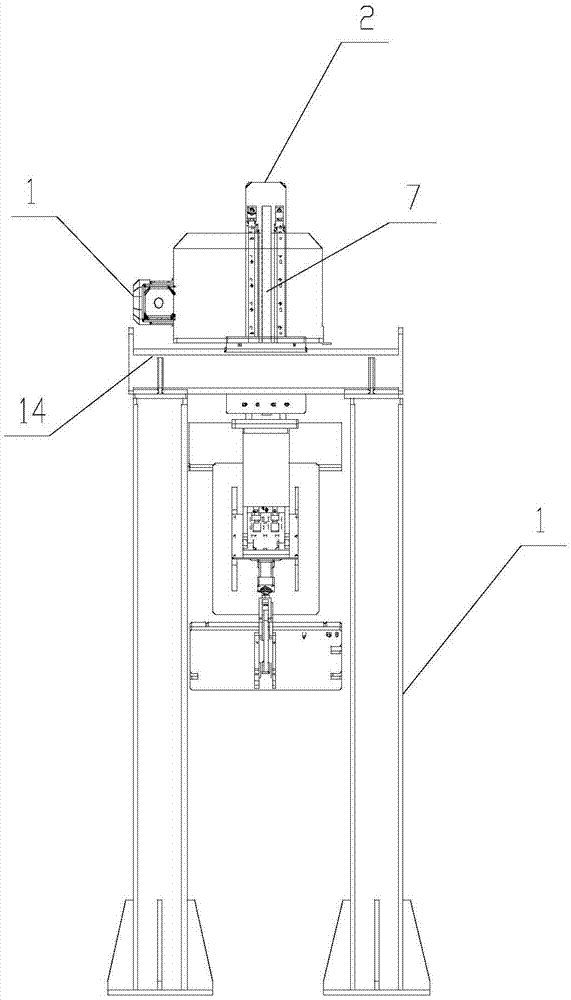

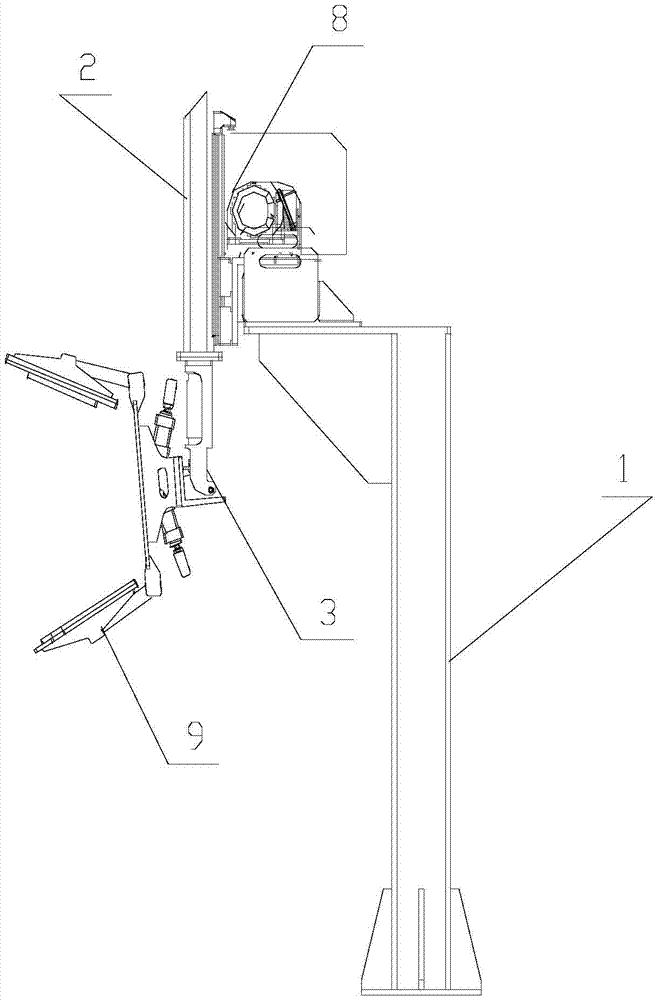

[0022] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the turning machine of household appliances includes a forward and reverse motor 1, an arm beam 2, a rack 7, a rotator 3, a connecting rod 4, a clamp 9, and two columns 5; the columns 5 are used to support the forward and reverse motor 1 The bottom of the column 5 is fixed on the ground by bolts; the tops of the two columns 5 are connected by a beam 14, and the forward and reverse motor 1 is arranged on the beam 14; the rotating shaft of the forward and reverse motor 1 is connected with a gear 8, and the arm beam 2 The side wall of the rack is vertically provided with a rack 7, the gear 8 and the rack 7 are meshed, and the motor controls the lifting of the arm beam 2 through the gear 8 and the rack 7; the bottom of the arm beam 2 is connected with the rotator 3 and the clamp 9 in turn ; The rotator 3 is connected with the first hydraulic cylinder 6 for driving the rotator 3 through the connecting rod 4 ...

Embodiment 2

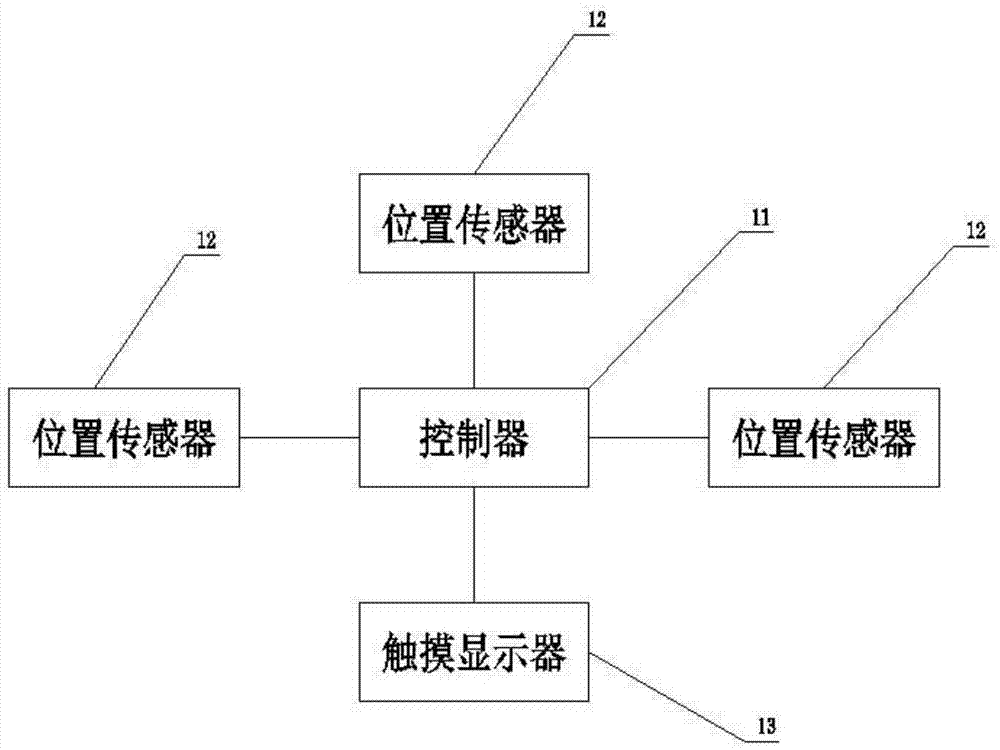

[0025] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the turning machine of household appliances also includes a controller 11; both the first hydraulic cylinder 6 and the second hydraulic cylinder 10 have piston rods, and the upper piston rod and the upper arm beam 2 Both are provided with a position sensor 12; the output end of the position sensor 12 is connected to the signal input end of the controller 11; the corresponding control signal output end of the controller 11 is respectively connected to the control signal input end of the forward and reverse motor 1, the first hydraulic cylinder 6 The control signal input end of the second hydraulic cylinder 10 is connected to the control signal input end; the controller 11 is connected with a touch display 13 for human-computer interaction and information input; the touch display 13 can be replaced by other equipment with display and input functions, such as Mouse, keyboard and disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com