Device for automatically penetrating paper pipe by air bulking shaft of cast film machine

A technology of inflatable shaft and automatic threading, applied in the directions of loading/unloading, transportation and packaging, winding strips, etc., can solve the problems of high production cost, high labor intensity, poor safety, etc., achieve a high degree of automation, reduce labor Strength, safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with preferred embodiments.

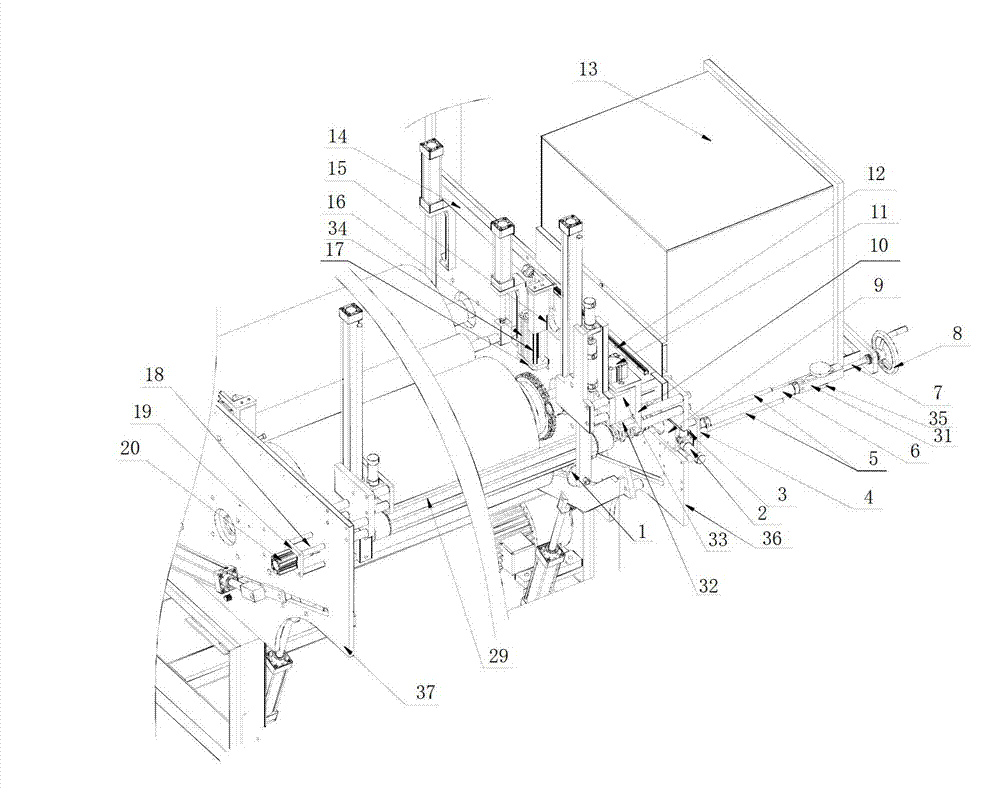

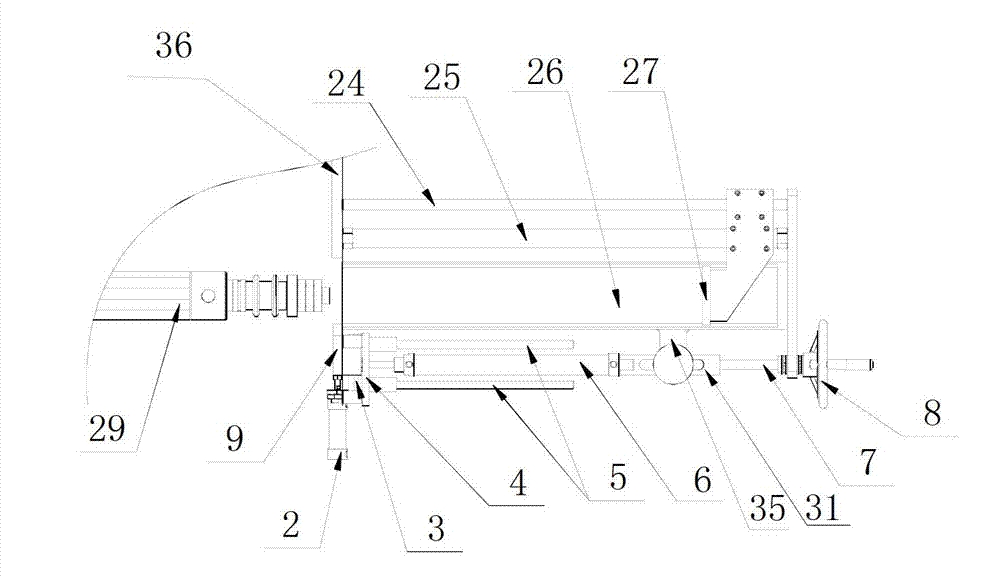

[0031] Such as Figure 1 to Figure 5 As shown, the automatic paper tube threading device for the air shaft of the cast film machine includes a paper tube hopper mechanism, a paper tube seat, a paper tube pushing mechanism, an air shaft inflation mechanism, and an air shaft support mechanism.

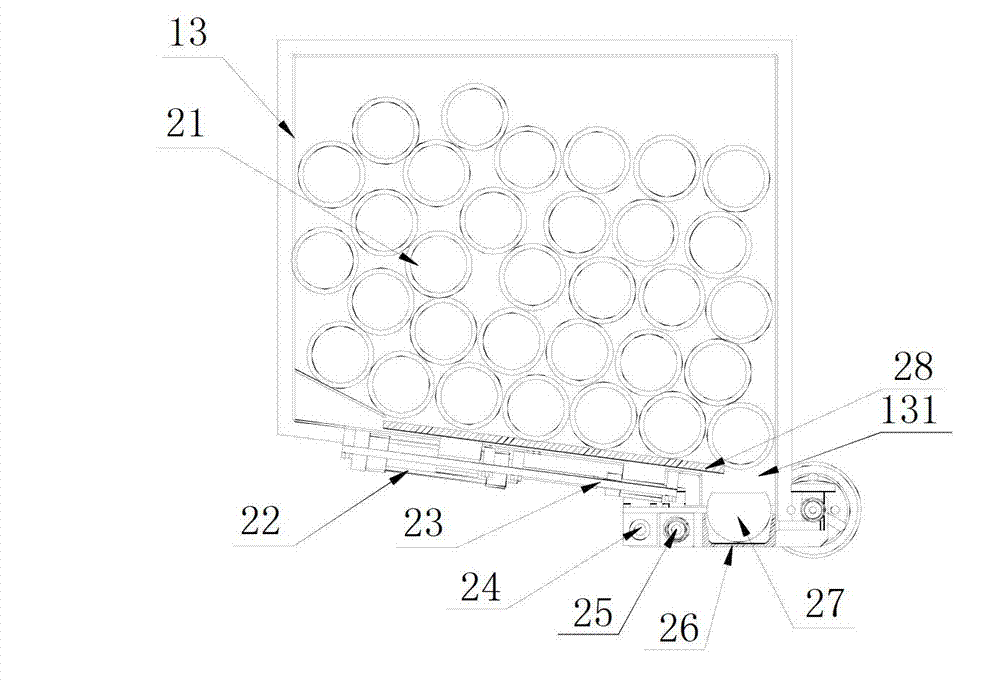

[0032] The paper tube hopper mechanism is located above the paper tube seat 26 and includes a paper tube hopper 13 and a paper tube baffle assembly; the paper tube hopper 13 includes a discharge port 131, and the paper tube baffle assembly includes a paper tube baffle 28, a paper tube baffle Plate slide bar 23 and paper tube baffle cylinder 22, paper tube baffle slide bar 23 and paper tube baffle cylinder 22 are fixedly installed on the bottom outside paper tube ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com