A casting production mechanism and manufacturing method of degradable courier slip labeling paper

A label paper, single sticker technology, applied in flat products, other household appliances, coatings, etc., can solve the problems of reduced uniformity of casting solution, poor quality of casting film, easy to float, etc., to improve production efficiency and improve The effect of production efficiency and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

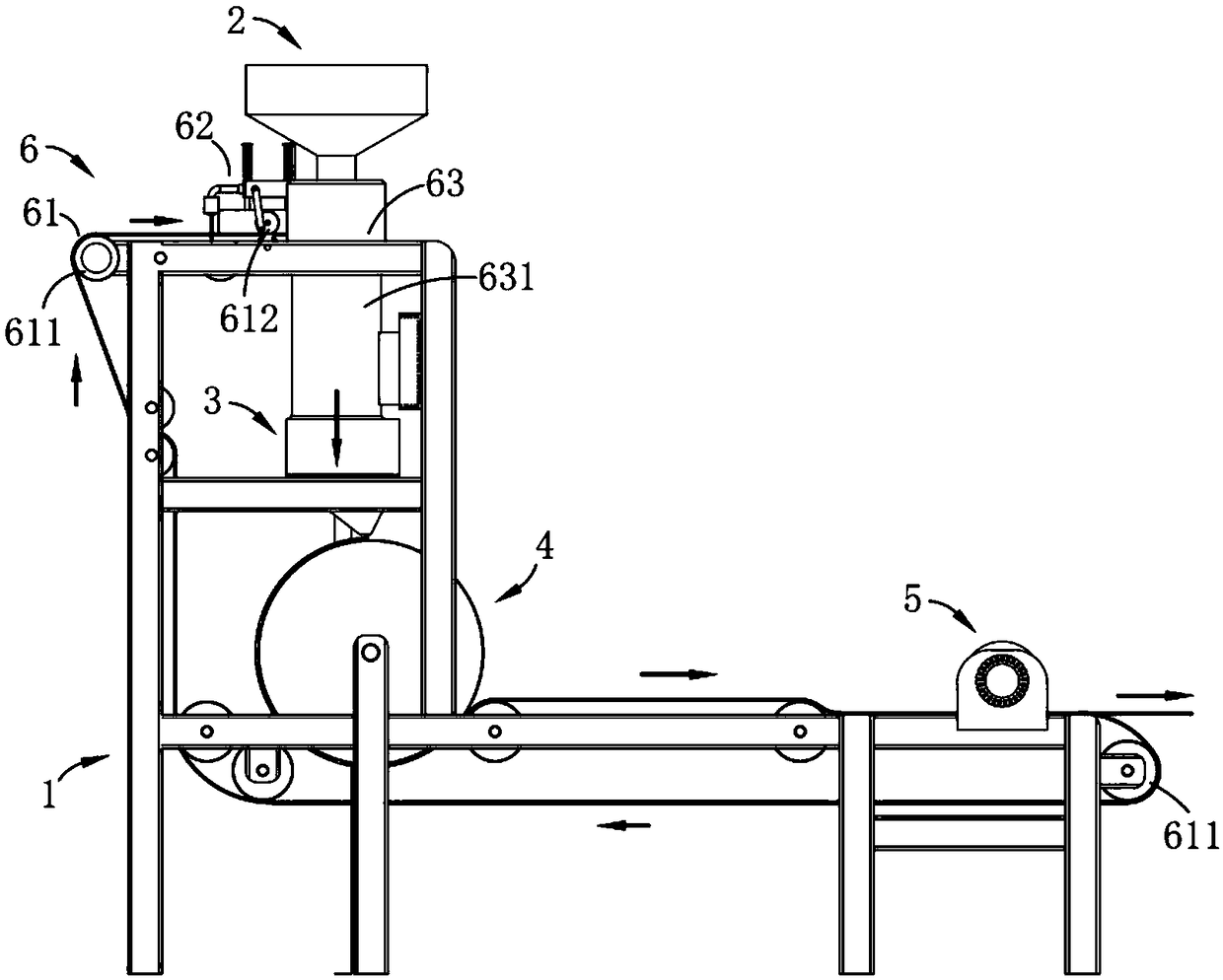

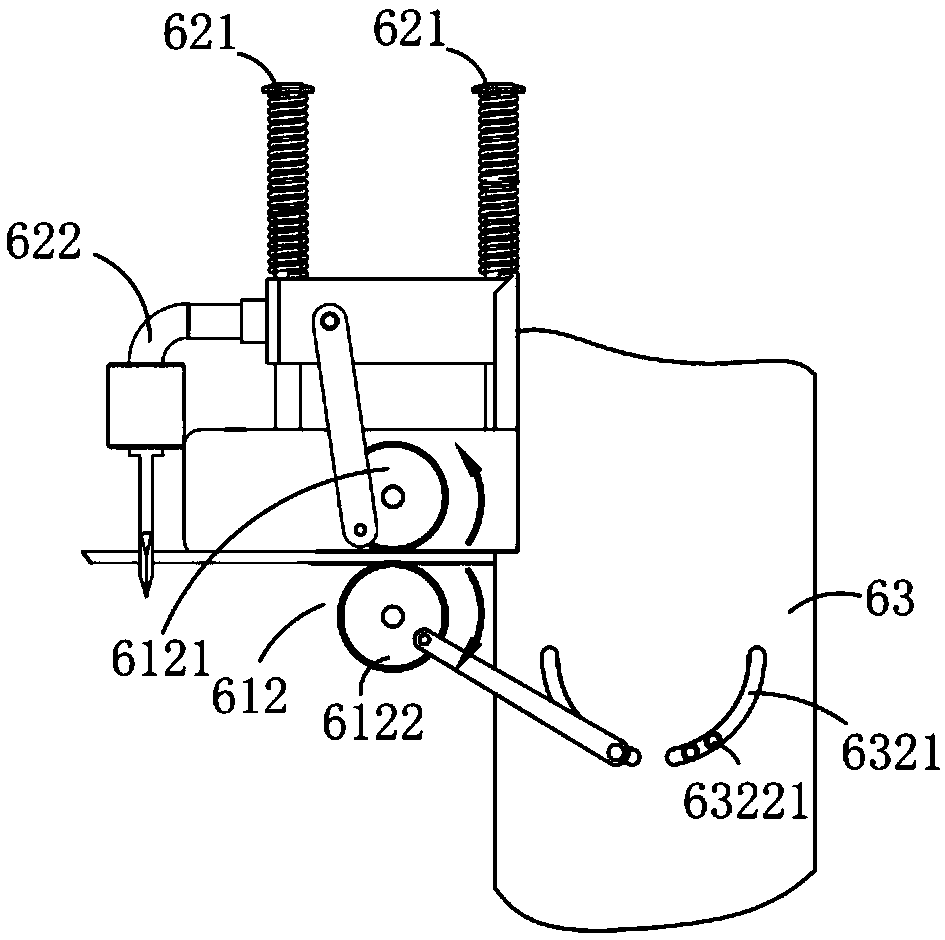

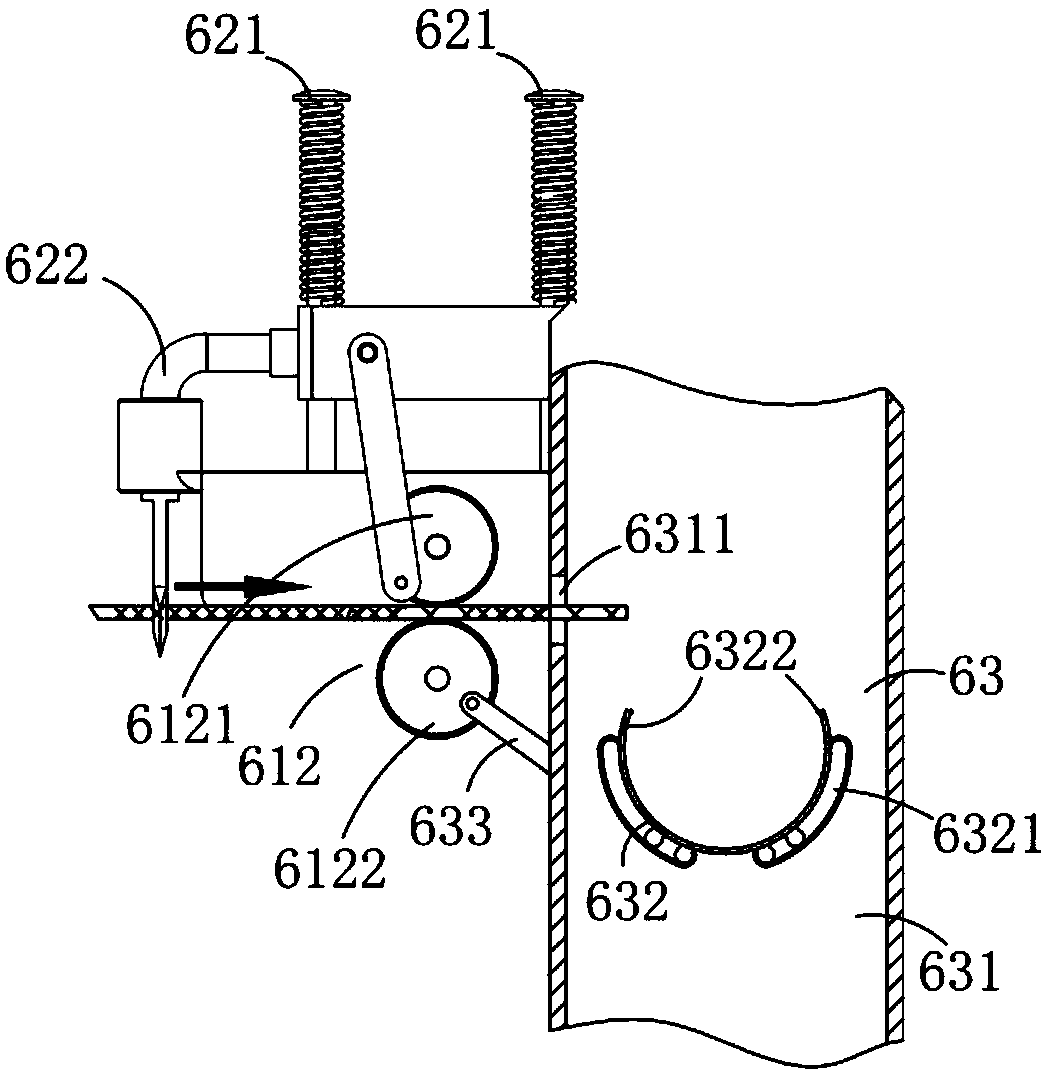

[0037] Such as figure 1 , 2 , 3, 4 and 5 shown, a kind of casting production mechanism of degradable courier single labeling paper, comprises frame 1, is arranged on this frame 1 and is used for the feeding bin 2 of new material feed, and this The feeding bin 2 is connected to the melting mechanism 3 for melting and liquefying the raw material, the casting roller 4 for casting and cooling the melted solution to form a film, and the shearing mechanism 5. The shearing mechanism 5 converts the formed casting film The two edges of ...

Embodiment 2

[0049] According to the drawings in the manual Image 6 Describe the casting method of a kind of degradable courier single labeling paper in embodiment two

[0050] A tape casting method for degradable courier labeling paper, comprising the following parts:

[0051] (a) The molten part is extruded after the molten raw material is liquefied by the melting mechanism 3;

[0052] (b) In the forming part, the solution extruded by the melting mechanism 3 enters the forming station, and the solution is cast on the surface of the casting roller 4 in the form of a film, which is quenched to form a wet film and then peeled off to output;

[0053] (c) Output part, after the wet film formed in step (b) is stretched, it is transported to the cutting station, and after being continuously rotated and trimmed by the shearing mechanism 5, the formed film and Edge material;

[0054] (d) Recycling part, which transfers the edge material generated in step (c) to the recycling station, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com