Automatic skip blanking apparatus of thread rolling machine

An automatic loading and unloading and thread rolling machine technology, applied in the direction of feeding device, thread cutting device, tangential feeding device, etc., can solve the problems of low productivity of manual loading and unloading, industrial accidents, etc., to increase labor productivity, reduce waste, reduce The effect of industrial accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

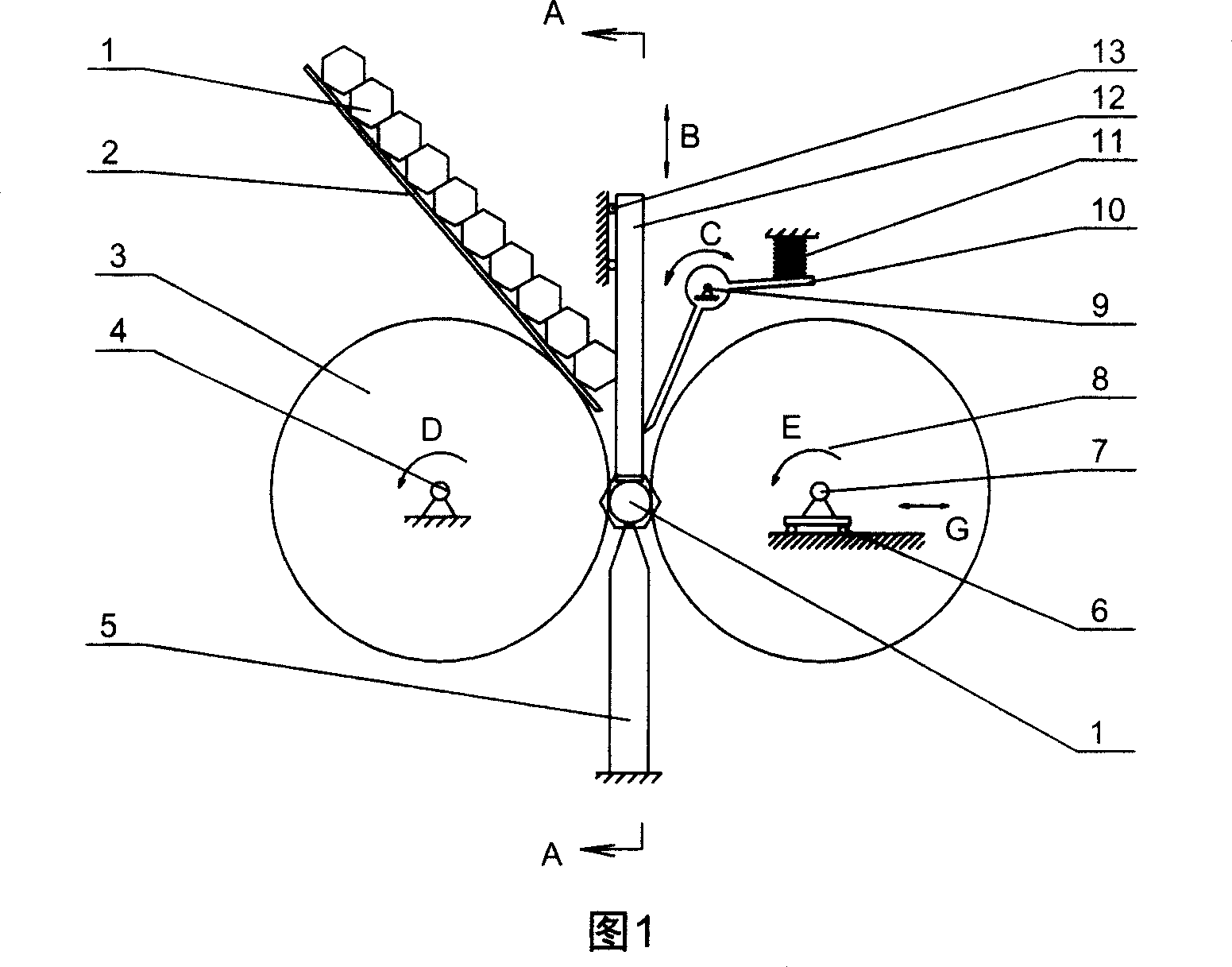

[0015] Fig. 1 is the structural representation of the present invention when feeding, including: 1. workpiece (screw blank, or the screw of making), 2. feeding chute, 3. fixed thread rolling wheel, 4. fixed thread rolling wheel center of rotation , 5. The workpiece support plate, 6. Moving the sliding guide rail of the rolling wheel, 7. The center of rotation of the moving rolling wheel, 8. The moving center of the rolling wheel, 9. The center of rotation of the feeding baffle, 10. The feeding baffle, 11 . Feeding baffle spring, 12. Feeding push rod, 13. Feeding push rod sliding guide.

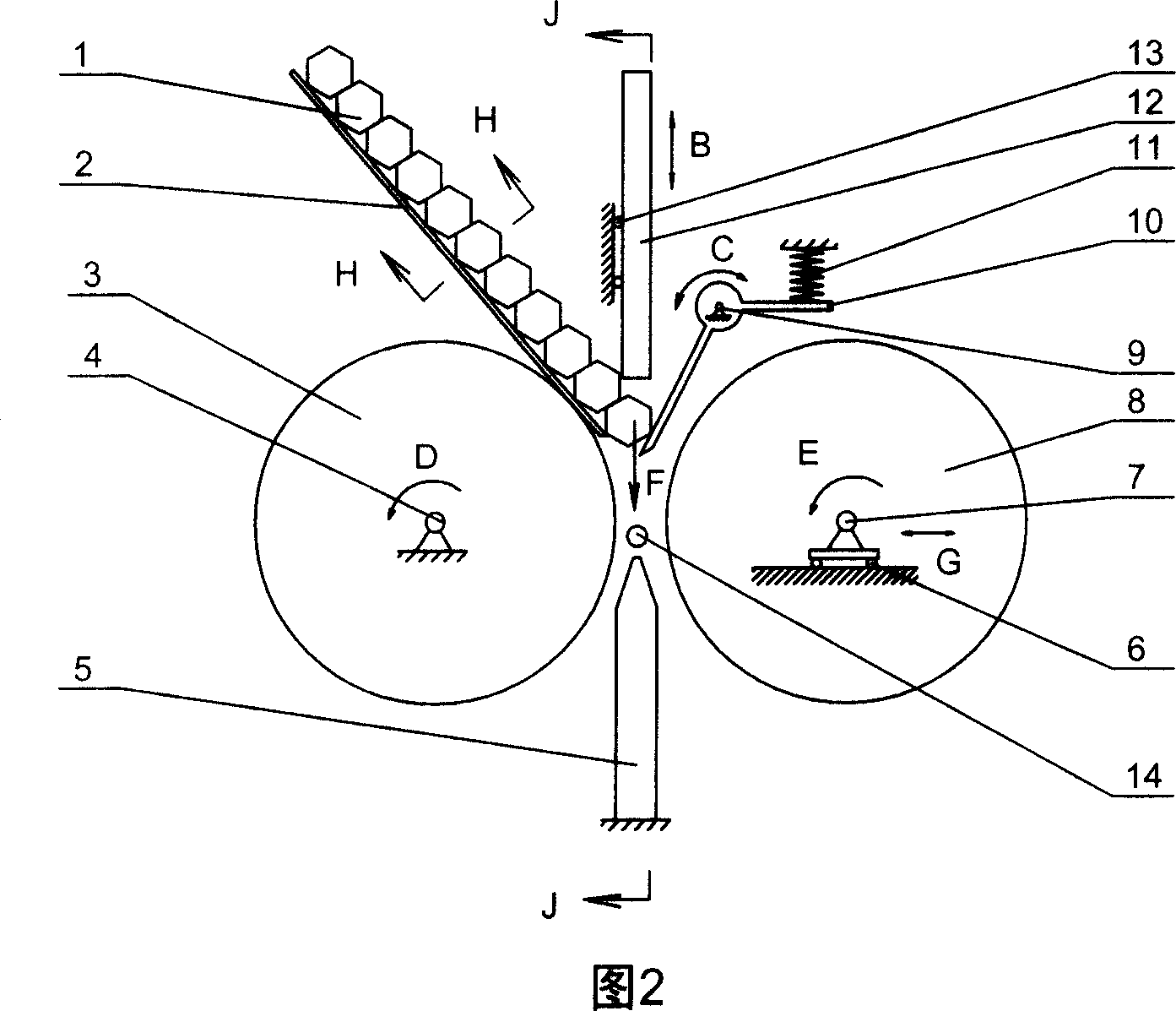

[0016] Fig. 2 is the structural representation of the present invention when discharging, in the figure: 14. discharging push rod.

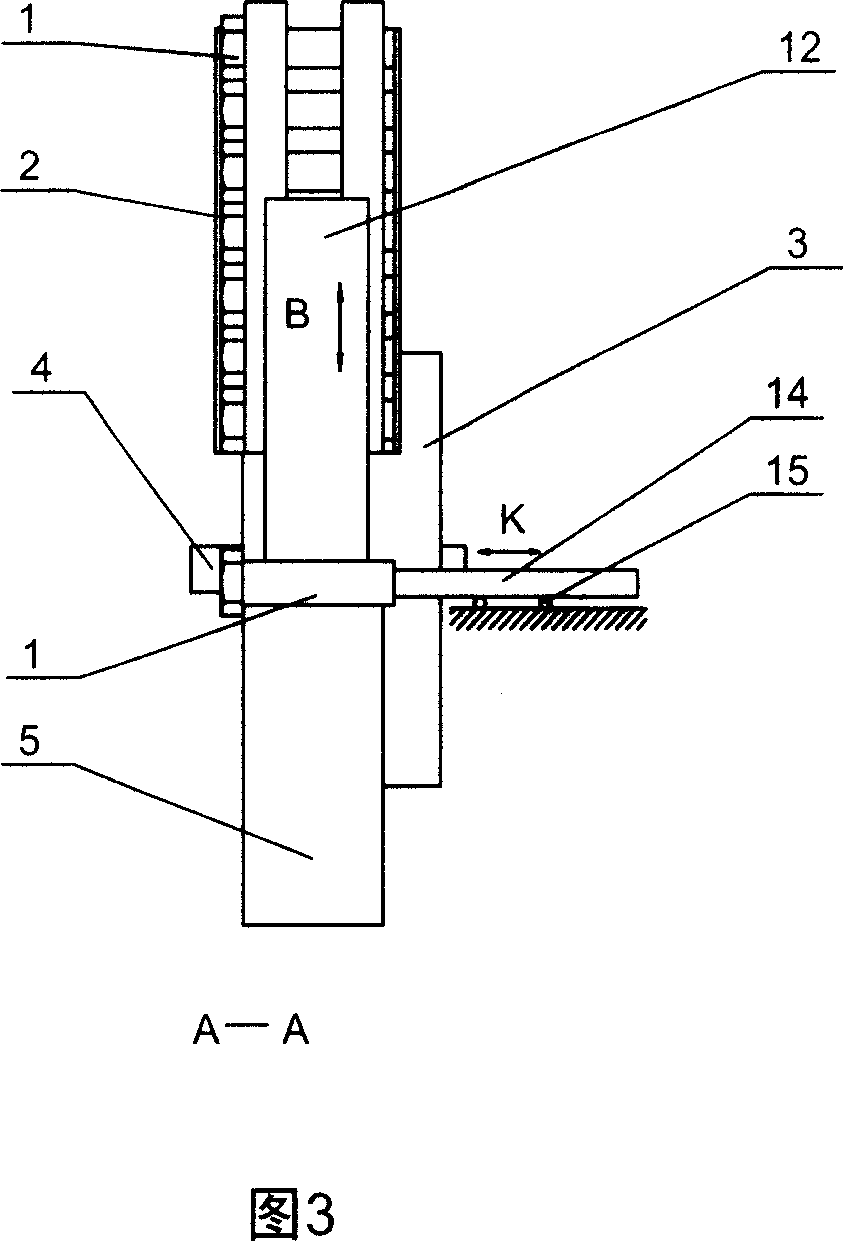

[0017] Fig. 3 is a schematic diagram of the structure of the present invention in the direction of A-A during material feeding, in the figure: 15. The sliding guide rail of the discharging push rod. Fig. 4 is a schematic diagram of the J-J direction structure of...

Embodiment 2

[0027] In this embodiment, other parts are the same as in Embodiment 1, and the difference is the pushing mechanism of the material-feeding and material-feeding push rods. The material-feeding and material-feeding push rod pushing mechanisms used in this embodiment are hydraulic cylinders. A hydraulic cylinder is connected to the feed push rod, and a hydraulic cylinder is also connected to the discharge push rod. The up and down, front and rear reversing of the two hydraulic cylinders are provided by the reversing valve, and the reversing signal comes from the position of the moving roller box. sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com