Photoelectric protection type button set-in machine

A technology of photoelectric protection and buttoning machine, which is applied in the direction of mechanical equipment, engineering safety devices, sewing tools, etc., can solve problems such as incoordination of hands and feet, pinch fingers of buttoning machine, increase enterprise operating costs, etc., to prevent Misoperation and the effect of reducing industrial accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

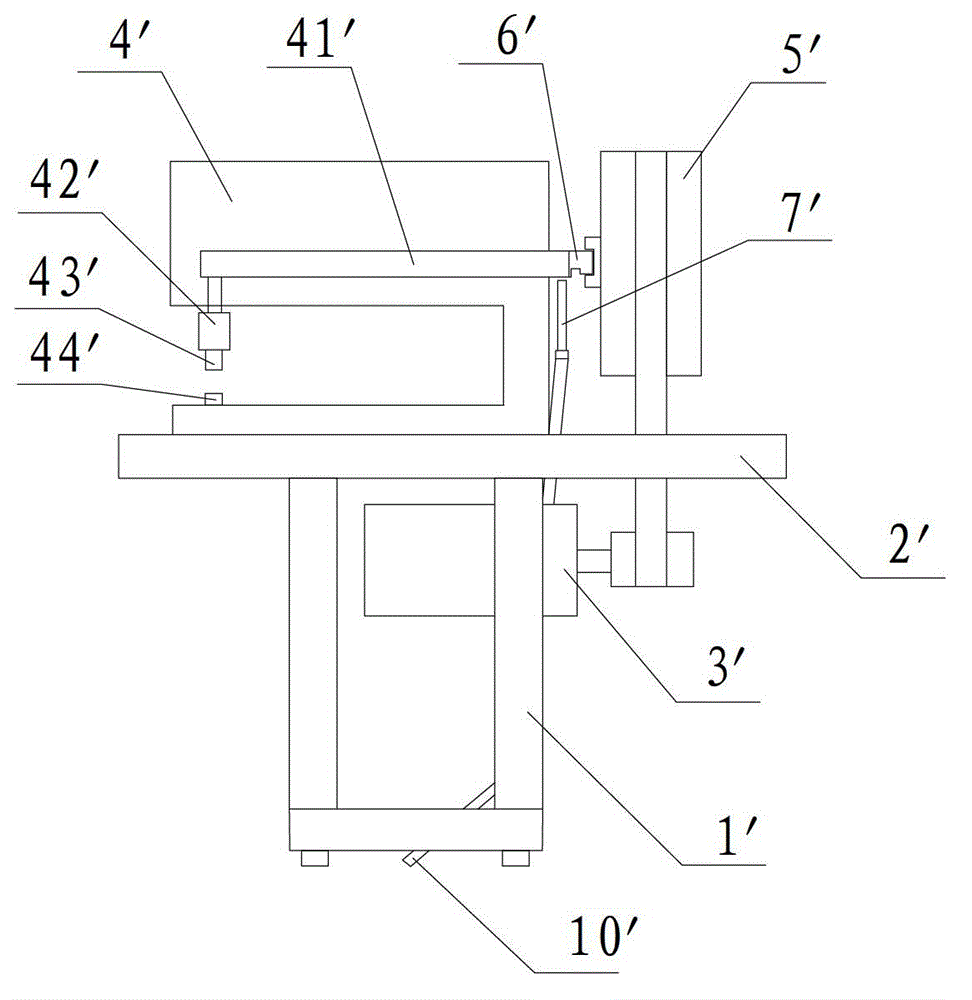

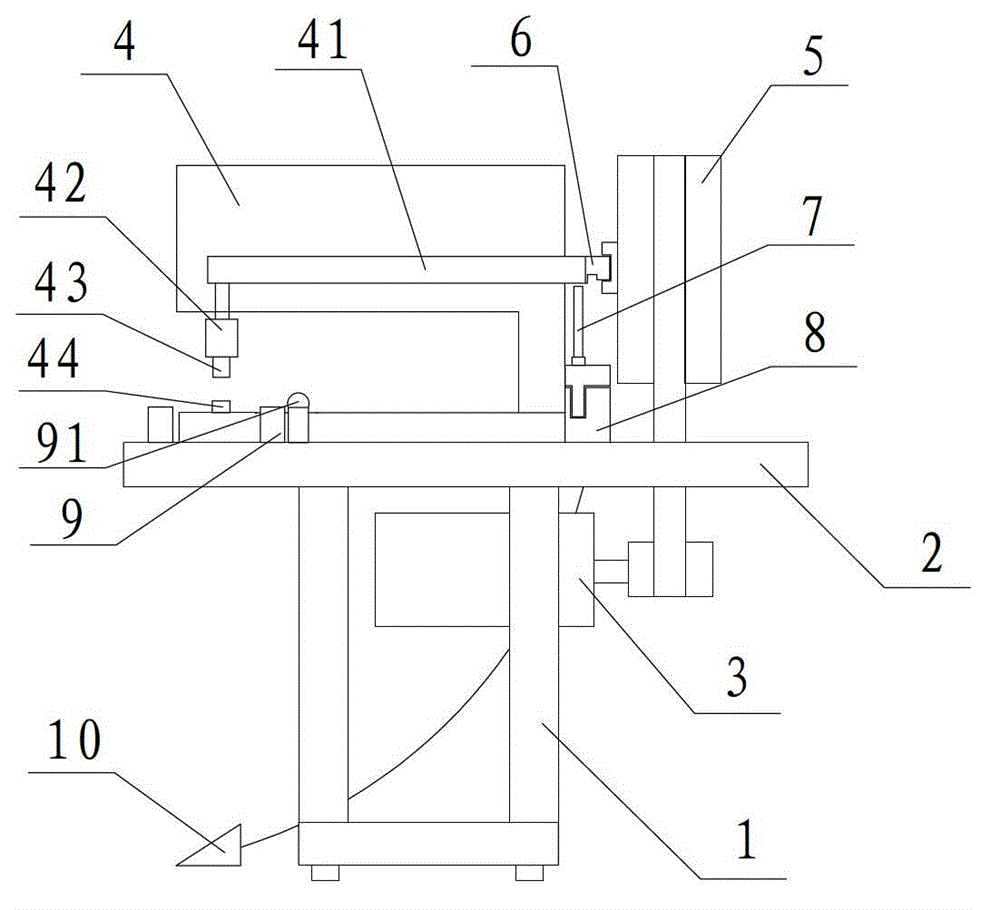

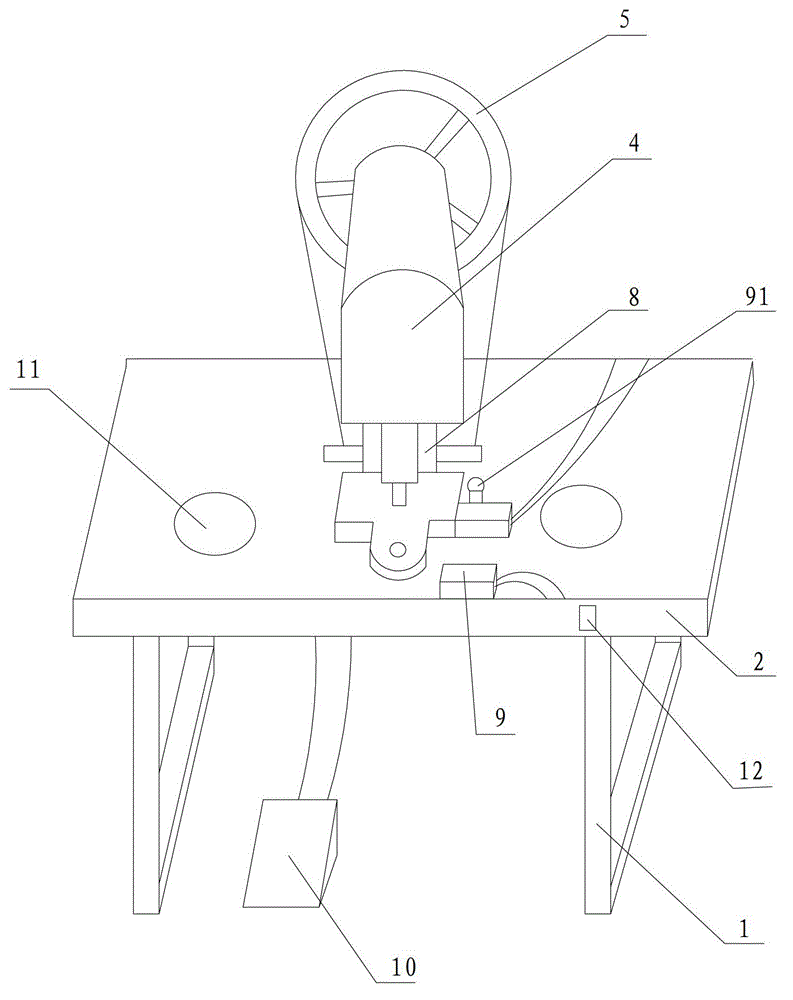

[0019] Such as figure 2 , 3 The shown photoelectric protection button loading machine mainly includes a support frame 1 , a workbench 2 , a motor 3 , a button loading machine body 4 , a transmission mechanism 5 , an electromagnetic module 8 , and a photoelectric induction module 9 . Wherein two support frames 1 are arranged in parallel and are perpendicular to the horizontal plane, the workbench 2 is fixed on the two support frames 1, and the motor 3 is fixed below the workbench 2 to provide power to the button loading machine body 4 through the transmission mechanism 5. The button loading machine body 4 is provided with a main shaft 41, one end of which is connected with the clutch 6, and one end is connected with the stamping head 42. An electromagnetic module 8 is fixed on the workbench 2 below the clutch 6 and is connected with it by a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com