Six-axis intelligent carrying mechanical hand for stamping

An intelligent manipulator, six-axis technology, applied in manipulators, program-controlled manipulators, claw arms, etc., can solve the problems that the workpiece cannot be placed in the required spatial position, the requirements for the degree of freedom of the machine are high, and the machine cannot be flexible. To achieve the effect of convenient teaching, improving production efficiency and simple teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

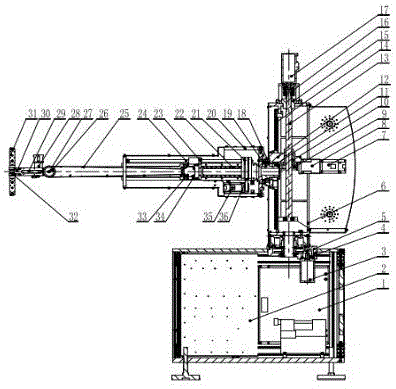

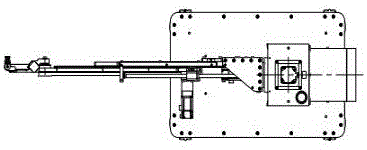

[0019] Such as figure 1 and figure 2 Shown: a six-axis intelligent manipulator for stamping and handling, including a swing arm rotation mechanism, a lifting movement mechanism, a flipping movement mechanism, a horizontal telescopic movement mechanism, an end rotation movement mechanism, and a gripper pitching movement mechanism, characterized in that: the pendulum The arm rotary motion mechanism is fixedly connected with the machine base 1, the lifting motion mechanism is fixedly connected with the swing arm rotary motion mechanism, the flipping motion mechanism is fixedly connected with the lifting motion mechanism, and the horizontal telescopic motion mechanism is connected with the flipping motion mechanism. The movement mechanism is fixedly connected, the terminal rotation movement mechanism is fixedly connected with the horizontal telescopic movement mechanism, the gripper pitch movement mechanism is fixedly connected with the end rotation movement mechanism, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com