Pneumatic sling for dual-purpose full-function automatic grappling hook

A full-featured, spreader technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of automatic lifting, work accident of hooking hands and fingers, inability to use pneumatic spreader grab hooks, etc., to avoid manual hooking. Operation, the effect of reducing the incidence of industrial accidents and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

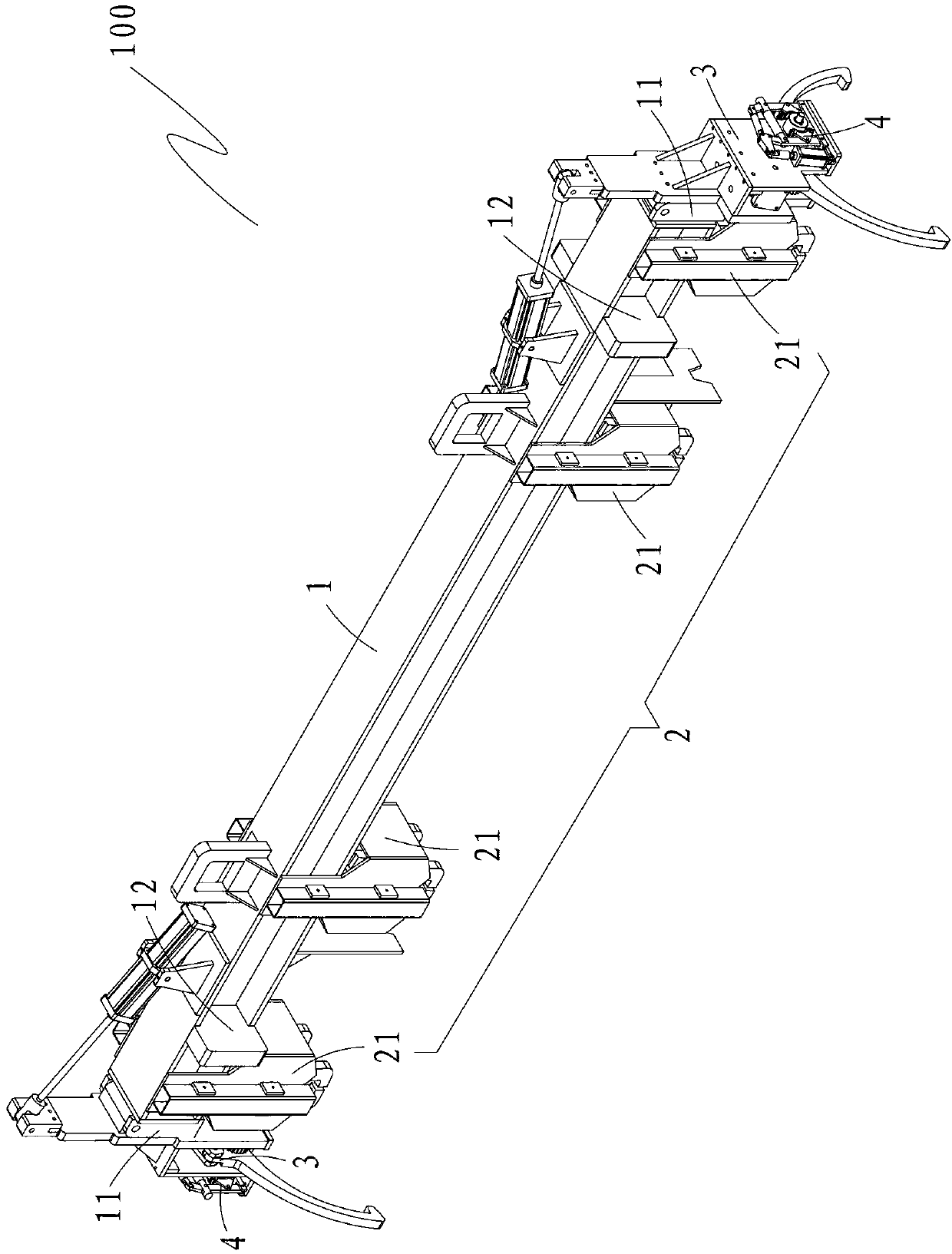

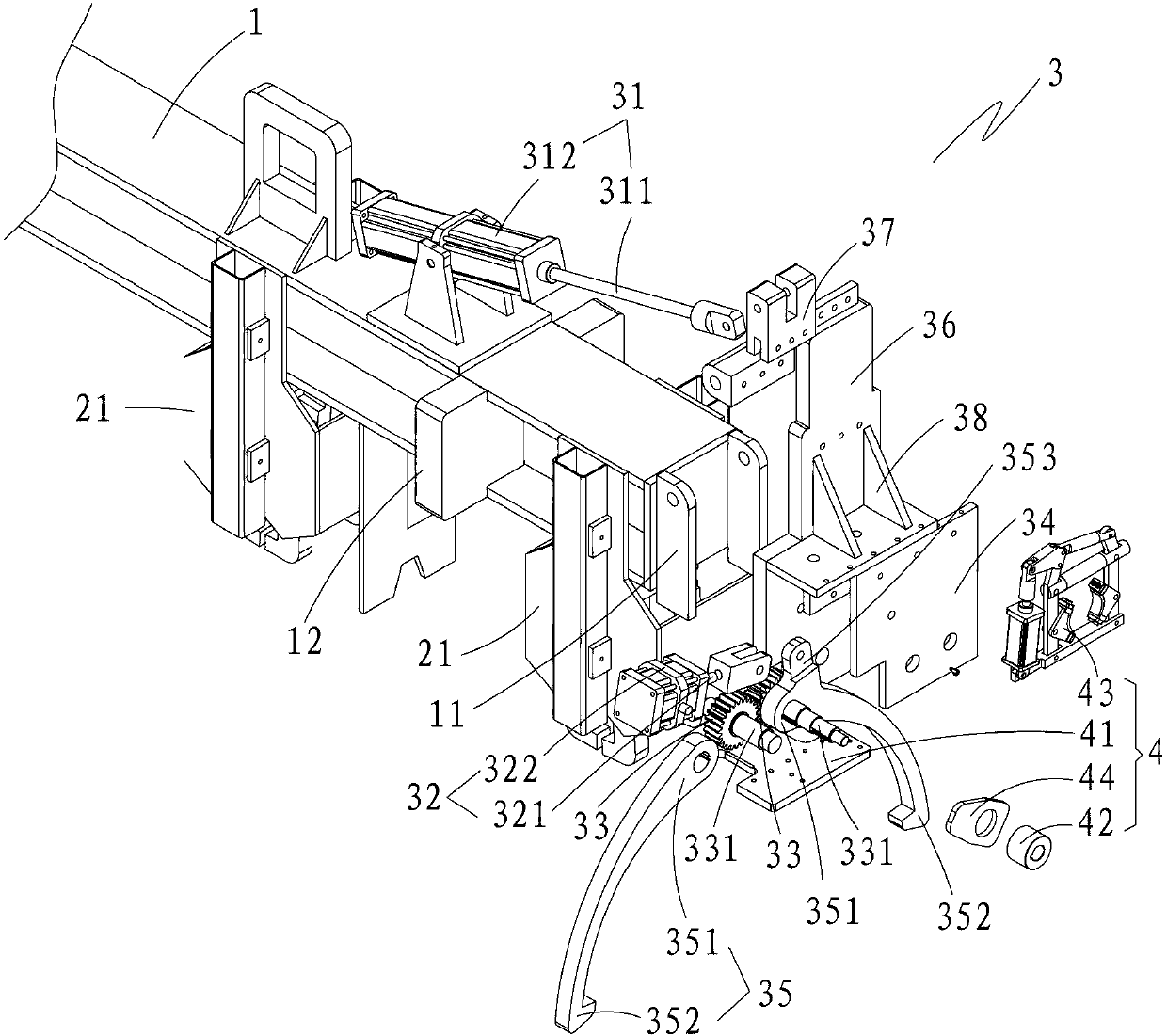

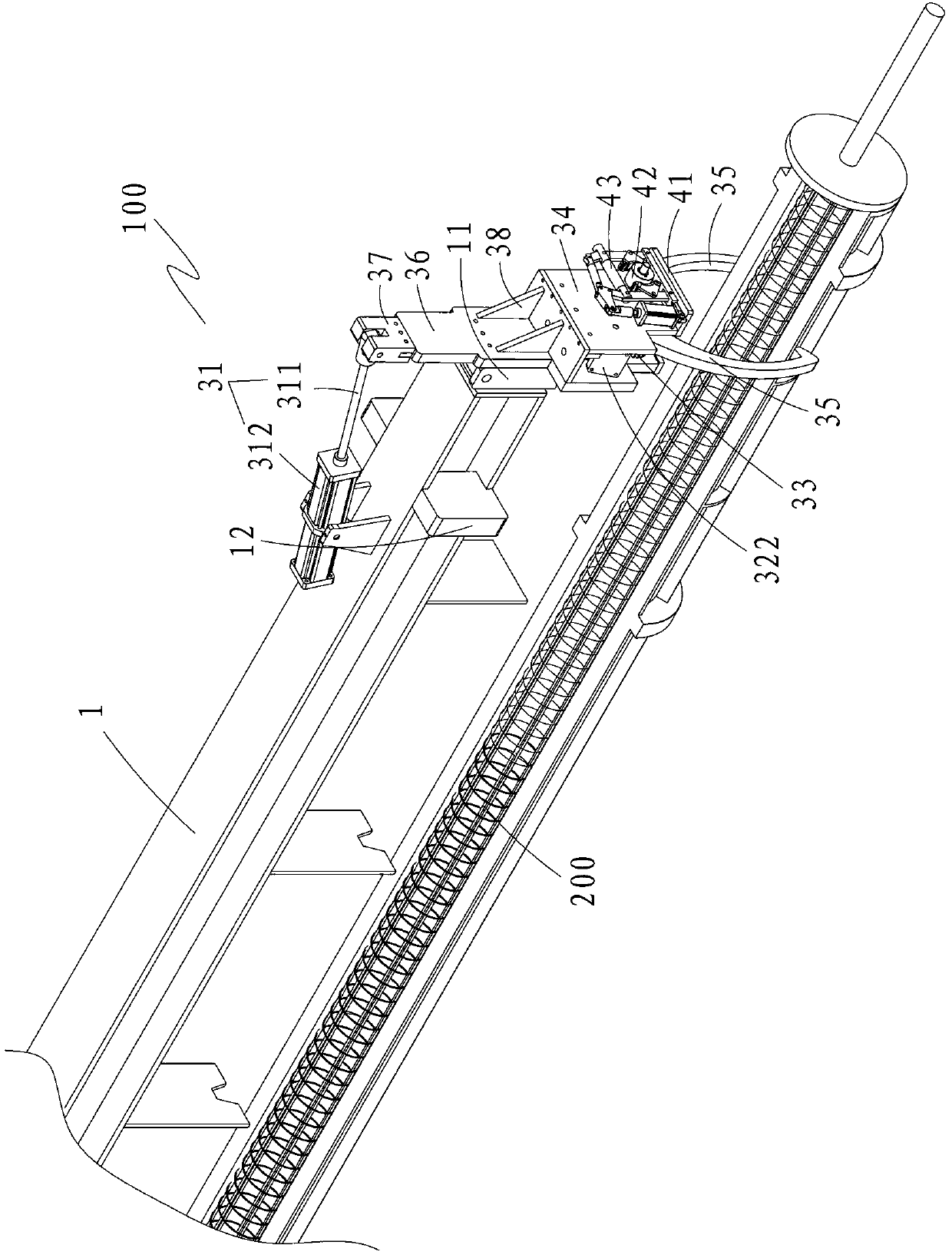

[0018] Please refer to figure 1 and figure 2 , the dual-purpose full-function automatic grab hook pneumatic spreader 100 of the present invention comprises a spreader main beam 1, a catch wheel system 2 made up of four catch wheel actuators 21, and one is used to control the entire pneumatic spreader 100 Provide a power source of compressed gas, and a control system, two hook-embracing bottom mold systems 3, and two safety brake mechanisms 4 respectively installed on the two hook-embracing bottom mold systems 3, each of the grabbing wheel actuators 21 Both are fixed on the main beam 1 of the spreader and connected with the power source and the control mechanism. The two hook-embracing bottom mold systems 3 are respectively connected to the two ends of the spreader main beam 1; each of the hook-embracing bottom mold systems 3 includes A first air cylinder 31, a second air cylinder 32, two intermeshing belt shaft gears 33, a gear box 34 for accommodating the two belt shaft gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com