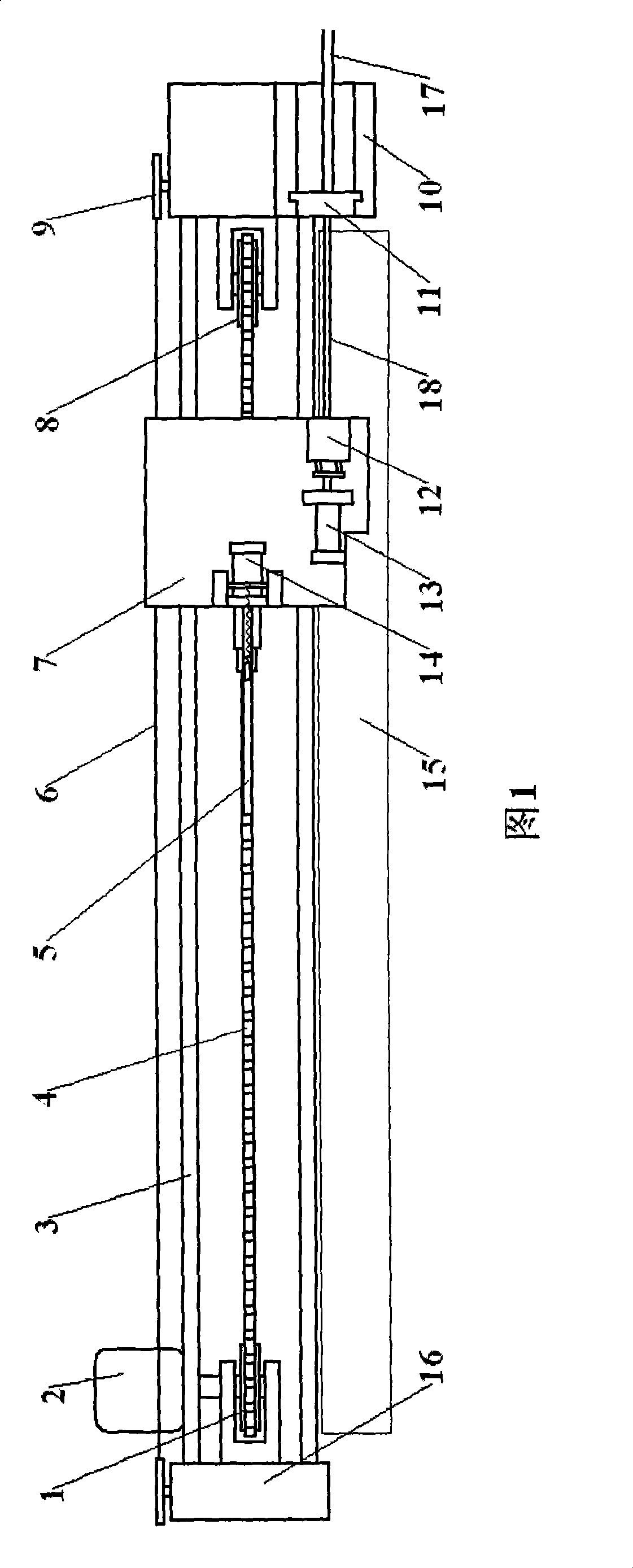

Automatic blanking system of vertical pulling machine of copper pipe

A straight-drawing machine and copper tube technology, which is applied in the field of metal material processing, can solve problems such as copper tube surface damage, high copper tube surface temperature, and mechanical failure, and achieve the effects of reducing labor intensity, avoiding mechanical influence, and avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

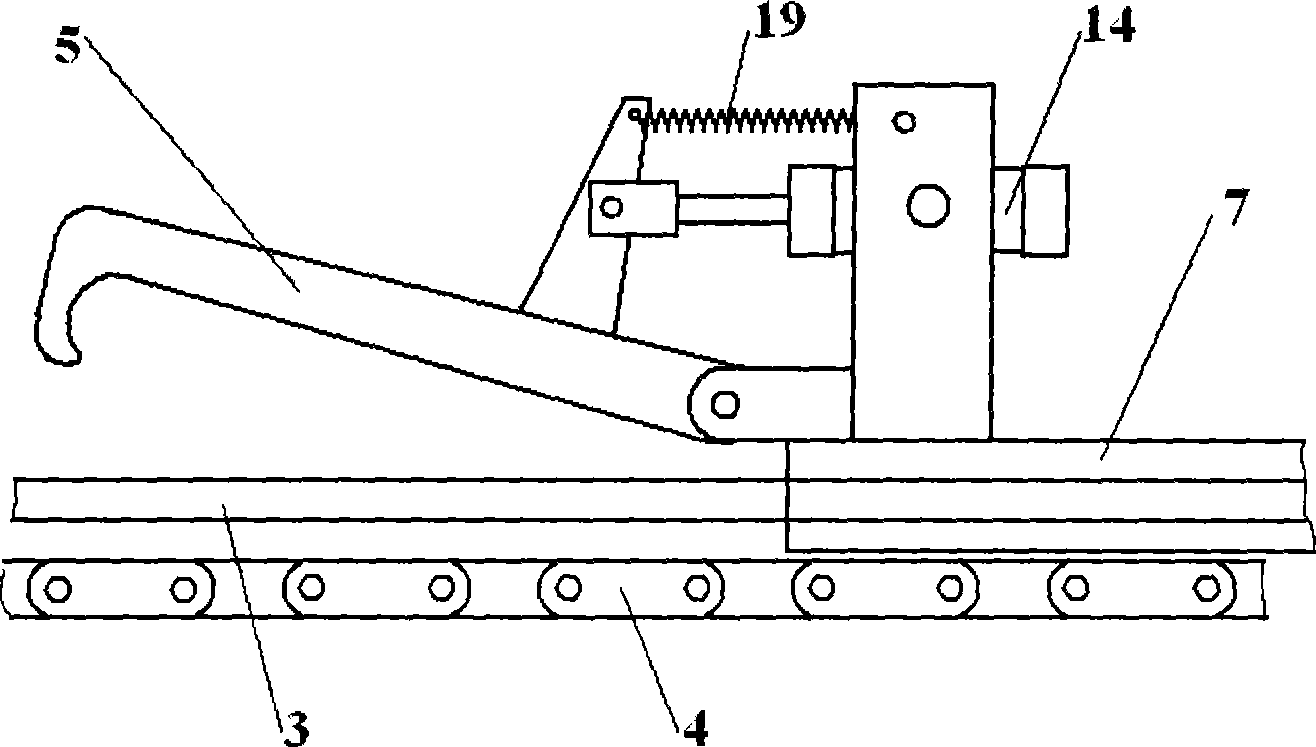

Embodiment 1

[0028] In order to protect the automatically falling copper tubes better, the present invention is outside the range of the guide rail 3 on the bed of the straight-drawing machine, below the described stretching slide 7 and the copper tube straightening die 11, A receiving bracket 15 made of flexible material is provided. The height of material receiving bracket 15 should make the distance that copper pipe falls reduces as far as possible, and the collision that suffers when the copper pipe after straightening is fallen is less.

Embodiment 2

[0030] On the basis of Embodiment 1, during implementation, the material receiving surface on the material receiving bracket 15 is parallel to the copper pipe being stretched, and the material receiving surface is provided with an inclination angle toward the outside of the fuselage. The function of the inclination angle is to make the copper tube roll outward after falling, and make room for the copper tubes that continue to fall in the future, so as not to collide with each other and affect the surface quality of the copper tubes.

Embodiment 3

[0032] On the basis of the second embodiment, in order to adjust the rolling speed of the fallen copper pipe, the inclination angle is adjustable, that is, an inclination angle adjustment mechanism is provided on the receiving bracket 15 . Because the inclination angle is too large, the copper pipes will roll too fast, and there will be more serious collisions between them; if the inclination angle is too small, the copper pipes may not be able to roll, and the avoidance effect will not be achieved.

[0033] The present invention adopts the above-mentioned technical scheme and provides different implementation examples, which are obviously different from the existing public technology, and have never been used in public. Compared with the prior art, it has made great progress in technology, and can Widely used in production. Therefore, the present invention has novelty, creativity and practicality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com