Reaction frame platform with movable bottom cushion plate

A technology of mobile platform and reaction force frame, which is applied in the testing, measuring devices, instruments and other directions of machines/structural components, can solve the problems of manual handling, inconvenient calibration, and self-heavy weight, so as to avoid bump damage and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In order to better understand the present invention, the present invention will be further described below in combination with the accompanying drawings.

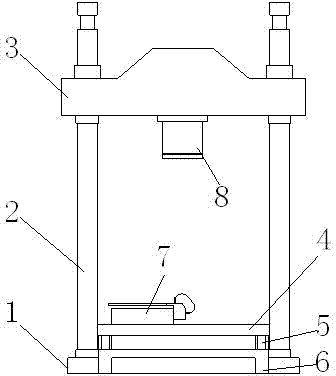

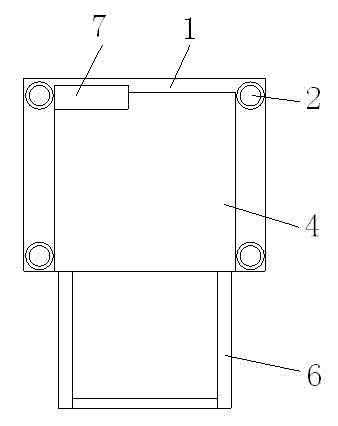

[0016] Such as figure 1 and figure 2 As shown, a reaction force frame platform with a movable base plate includes a base, a column 2 vertically arranged on the base, and an upper beam 3 is fixedly arranged above the column 2, and the upper beam 3 A sensor 8 is arranged below, and also includes a chassis 6 and a movable platform 4, the chassis 6 is arranged on the base 1, the movable platform 4 is arranged on the chassis 6 and can move back and forth along the upper surface of the chassis 6 , the movable platform 4 is provided with an oil pump 7 . The jack to be tested can be placed on the movable platform 4 manually or mechanically, and then the movable platform 4 can be pushed to be pushed into the frame of the reaction frame.

[0017] In order to reduce the frictional force between the movable platform 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com