Large shielding motor stator shielding sleeve assembling process

A technology for shielding motors and assembly processes, applied in the manufacture of stator/rotor bodies, etc., can solve the problems of bump damage, shielding sleeve extrusion deformation, small assembly gap, etc., to reduce bumps, ensure machining accuracy, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

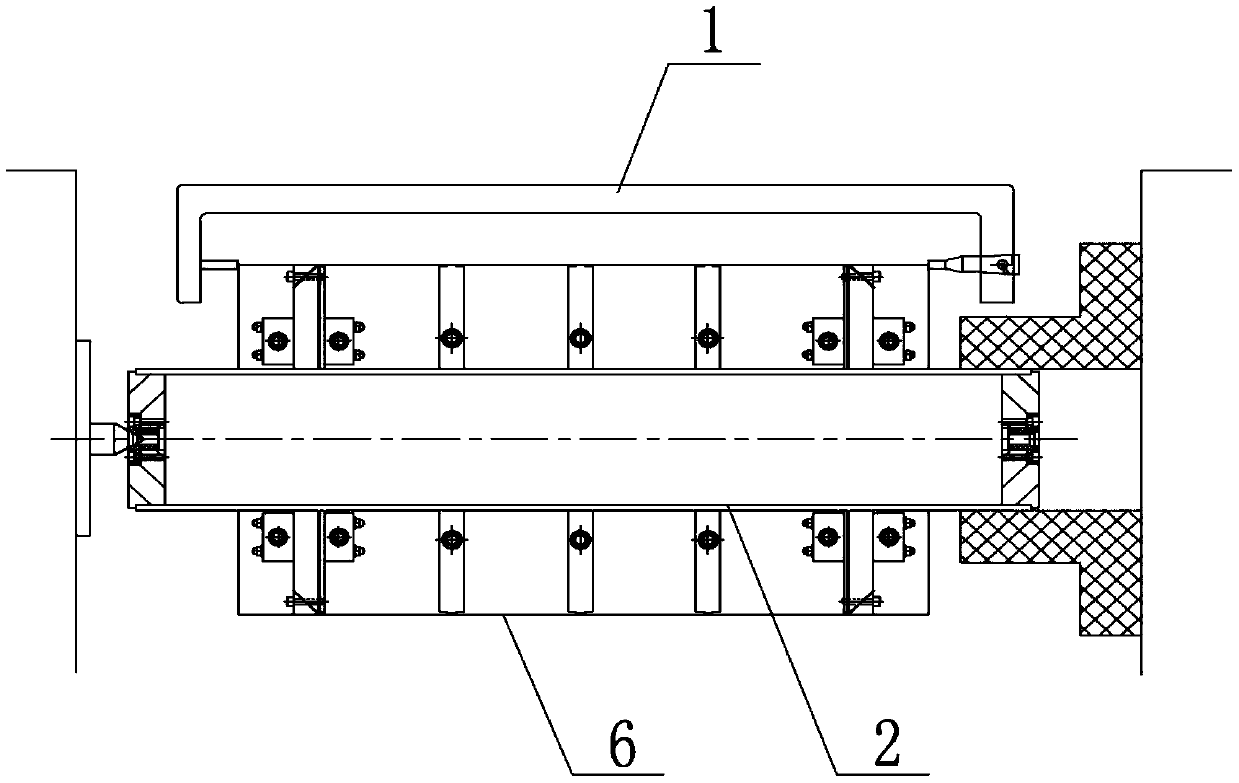

[0020] Such as Figure 4 As shown, a large-scale shielded motor stator shielding sleeve assembly process uses a precision measuring micrometer 1, a shielding sleeve tire expansion 2, a shielding sleeve assembly guide tool 3, a crane 4, and a limit stop 5 to carry out assembly. The method includes the following step:

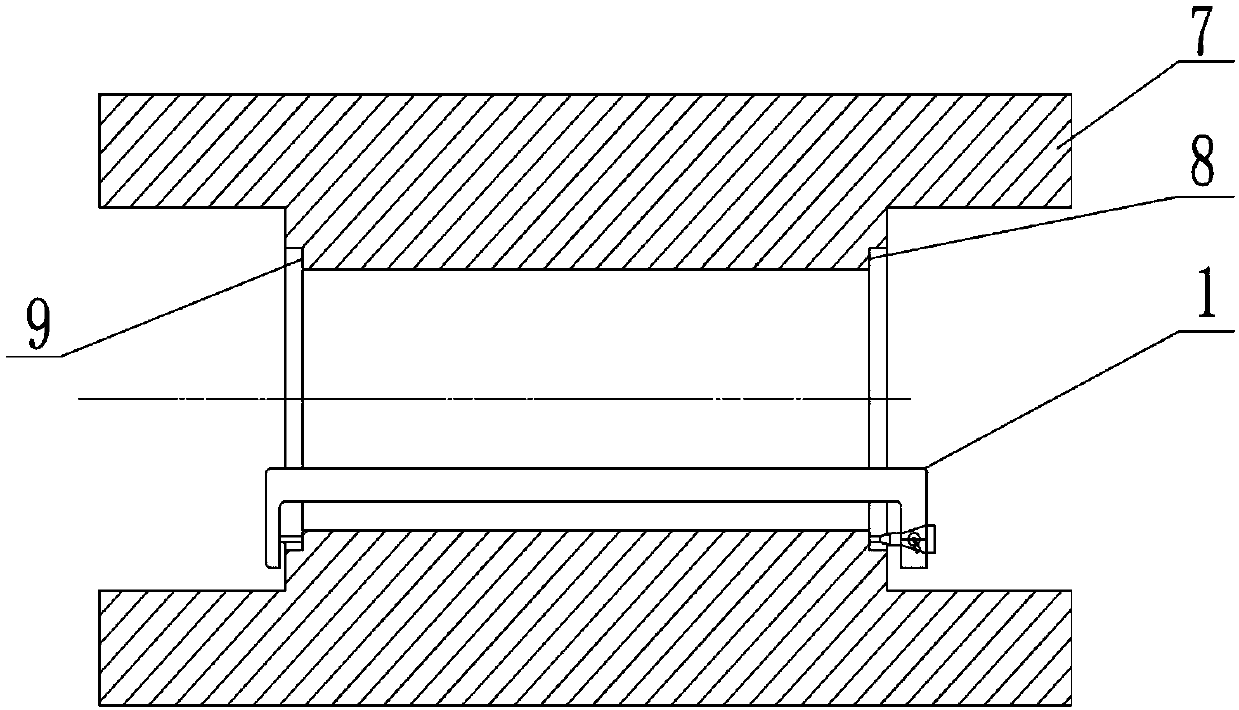

[0021] a) if figure 1 As shown, use a precision measuring micrometer 1 to measure the distance between the weld bevel 8 of the shield sleeve ring at the upper end of the stator and the weld bevel 9 of the shield sleeve ring at the lower end of the stator, that is, the theoretical length of the shield sleeve, measured when the stator is placed horizontally, Always keep the precision measuring micrometer in a horizontal state, rotate the stator to measure 4 places evenly and take the average value;

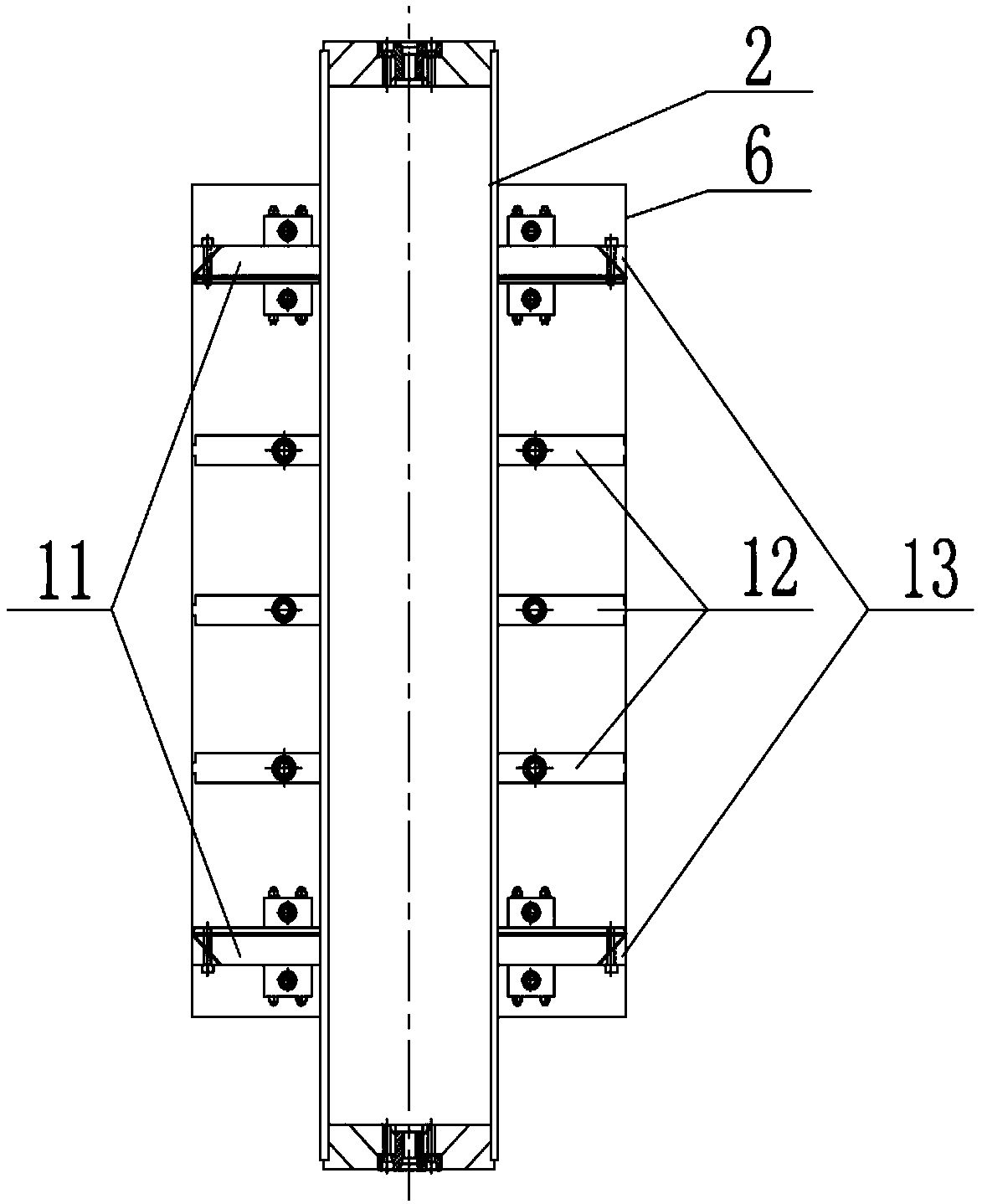

[0022] b) if figure 2 As shown, install the shielding sleeve expansion tire 2 into the shielding sleeve 6, and tighten the shielding sleeve by tightening the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com