Method for simulation test of self-changing gearbox and test device using same

An automatic transmission and simulation test technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of inability to meet mass production, inability to achieve simulated installation, slow production rhythm, etc., to meet mass production and realize automated testing. , the effect of avoiding work-related accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

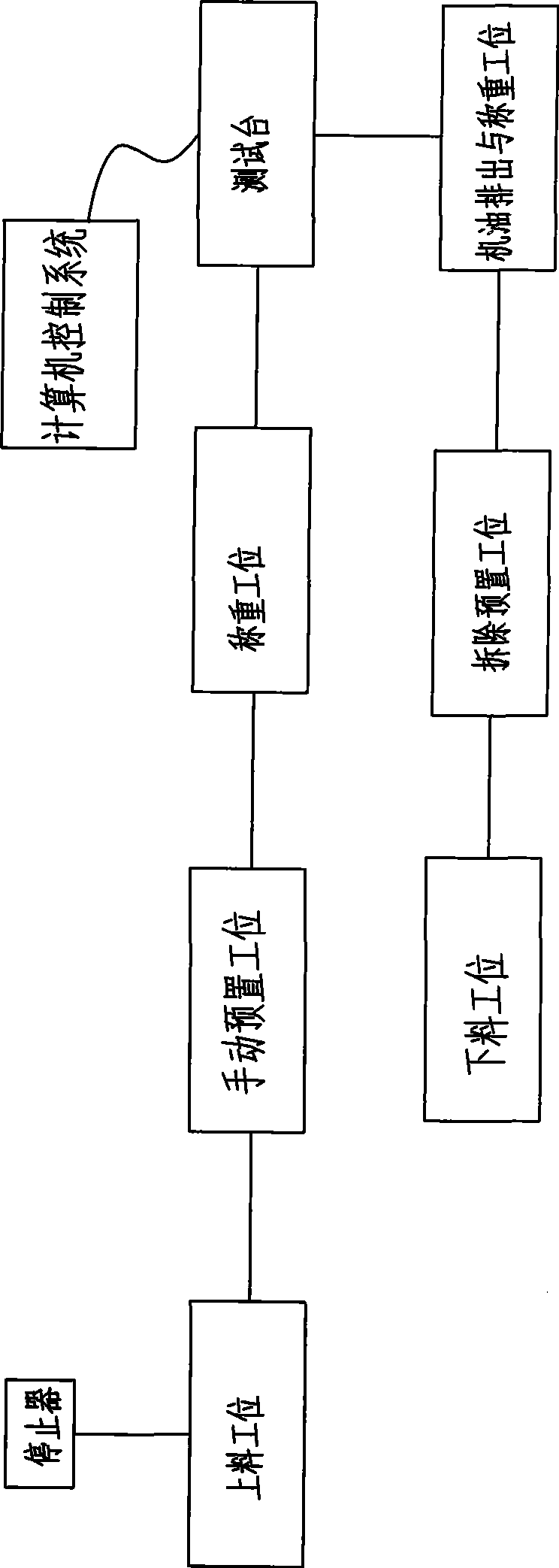

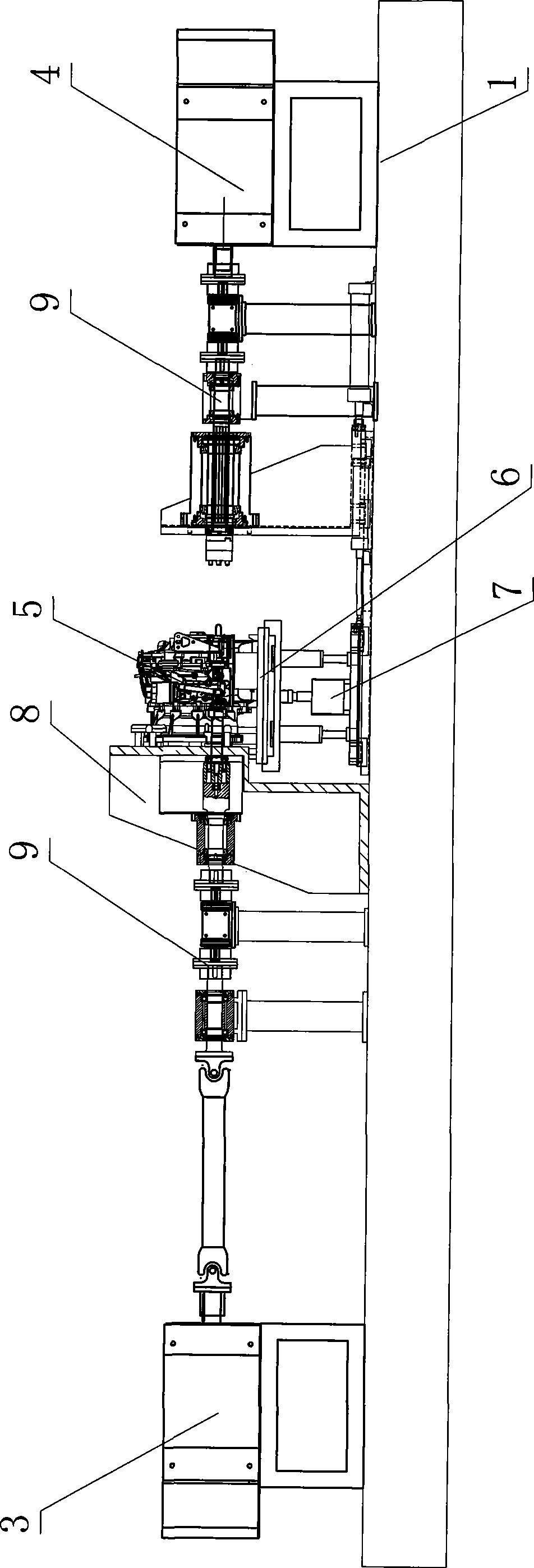

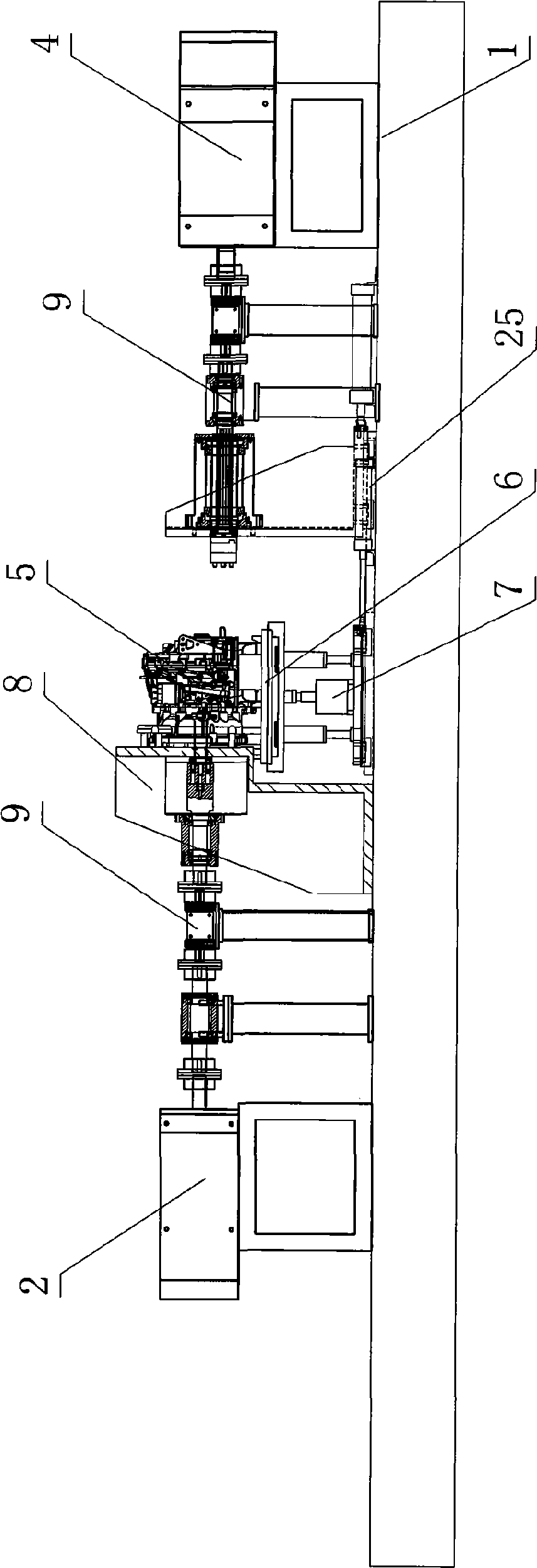

[0016] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the test device in the present invention includes a conveying line, and the conveying line is sequentially equipped with a feeding station, a manual preset station, a weighing station, a test bench, an oil discharge and weighing station, a removal preset station, and a blanking station. Work station, a stopper is installed in front of the conveyor belt, and the test bench is connected to the computer control system. The test bench includes a working table 1, an input motor 2, two output motors 3, 4, an automatic gearbox 5 is supported on a working table 6, a jacking translation device is installed on the lower part of the working table 6, and a fixed wall plate is installed on one side of the working table 6 8. An input motor 2 and an output motor 3 are installed on one side of the fixed wallboard 8, and another output motor 4 is installed on the other side of the workbench 6. The input motor 2 and two ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com