Punching manipulator

A technology of manipulators and cabinets, applied in the field of stamping devices, can solve problems such as work-related accidents, hand-crushing and disability, and insecurity, and achieve the effects of speeding up machine operation, saving machine investment, and eliminating work-related disability accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

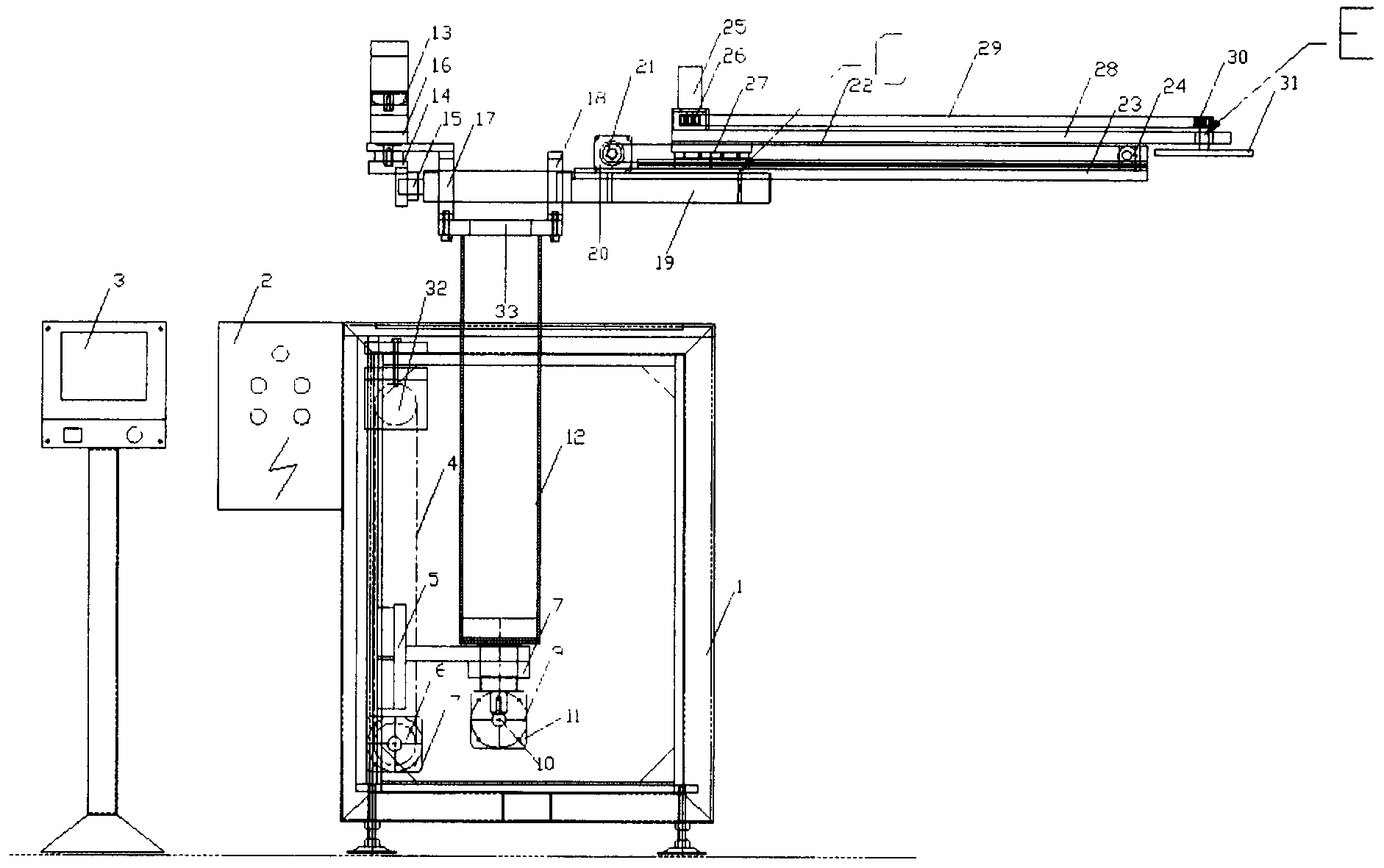

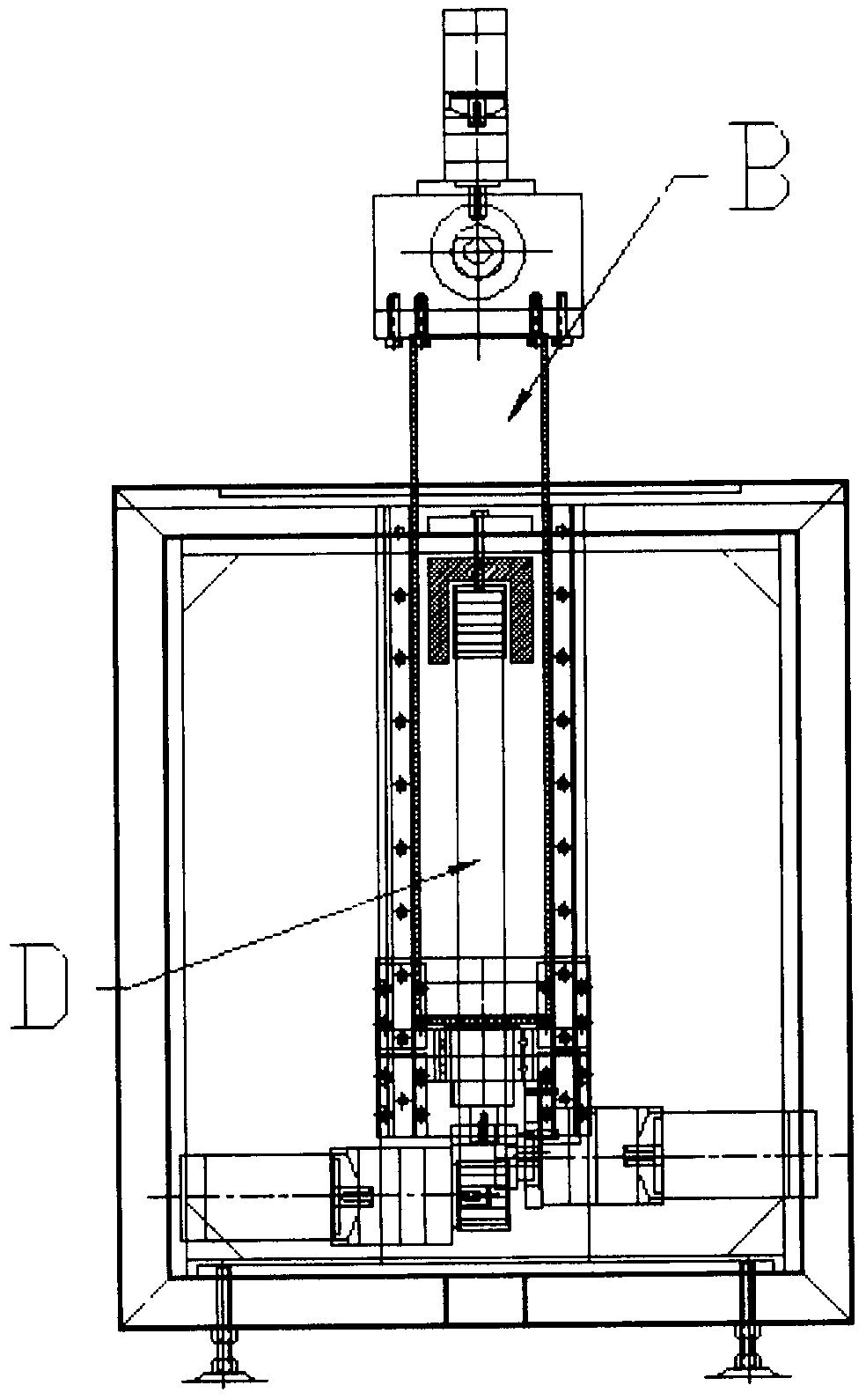

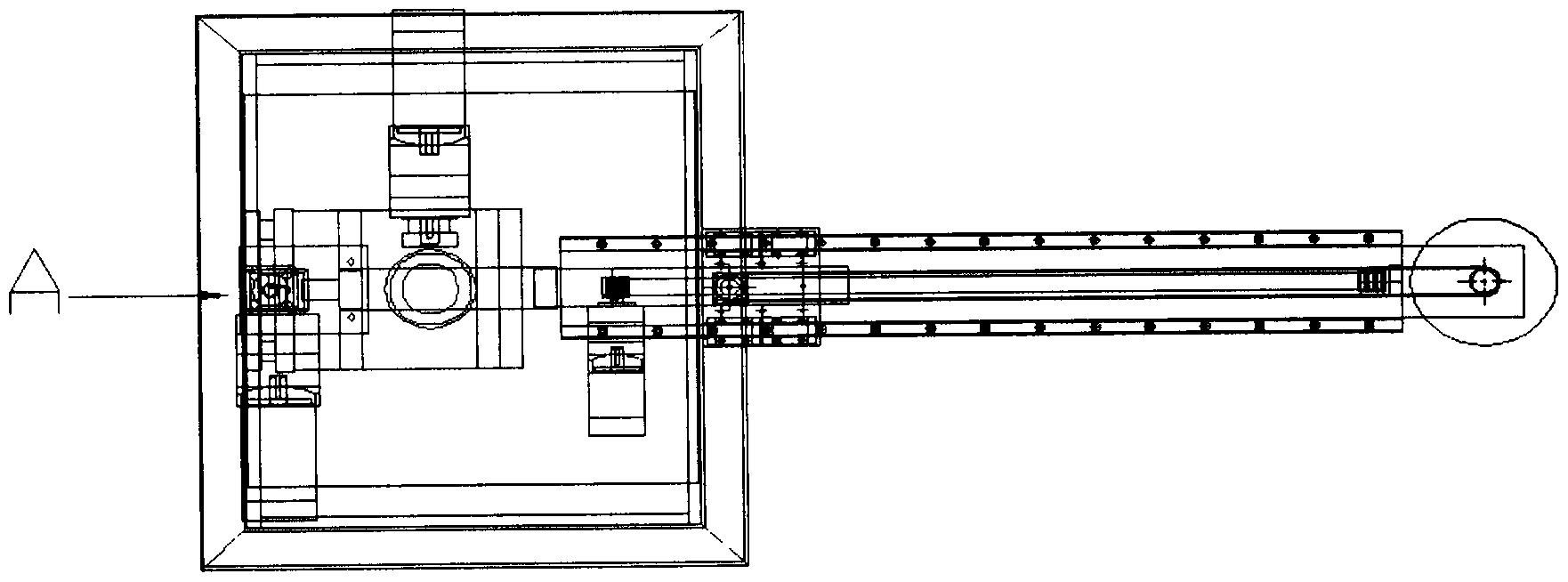

[0011] Below in conjunction with accompanying drawing, content of the invention will be further described:

[0012] refer to Figure 1-Figure 3 As shown, the stamping manipulator includes a cabinet 1, and the cabinet 1 is provided with a power distribution cabinet 2, and the cabinet 1 includes a first synchronous wheel 32 and a second synchronous wheel 32 that are surrounded by a first synchronous belt 4 from top to bottom. A synchronous wheel 6, the first synchronous belt 4 is also provided with an upper and lower sliding plate 5, the first servo motor 7 is driven to connect the second synchronous wheel 6, and the upper and lower sliding plates 5 are in phase with the swing arm support plate 7 in the cabinet 1 connection, the swing arm support plate 7 is driven and connected with the second servo motor 9 through two adapted first taper gear sets (10; 11), and the swing arm support plate 7 is also connected with the swing arm extending into the cabinet 1 One end of the column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com