Industrial robot motor band-type brake controller with safety monitoring device

An industrial robot, motor holding brake technology, applied in manipulators, manufacturing tools, etc., can solve the problems of U-turn, button aging failure, operator injury, etc., and achieve the effect of simple structure, low cost and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

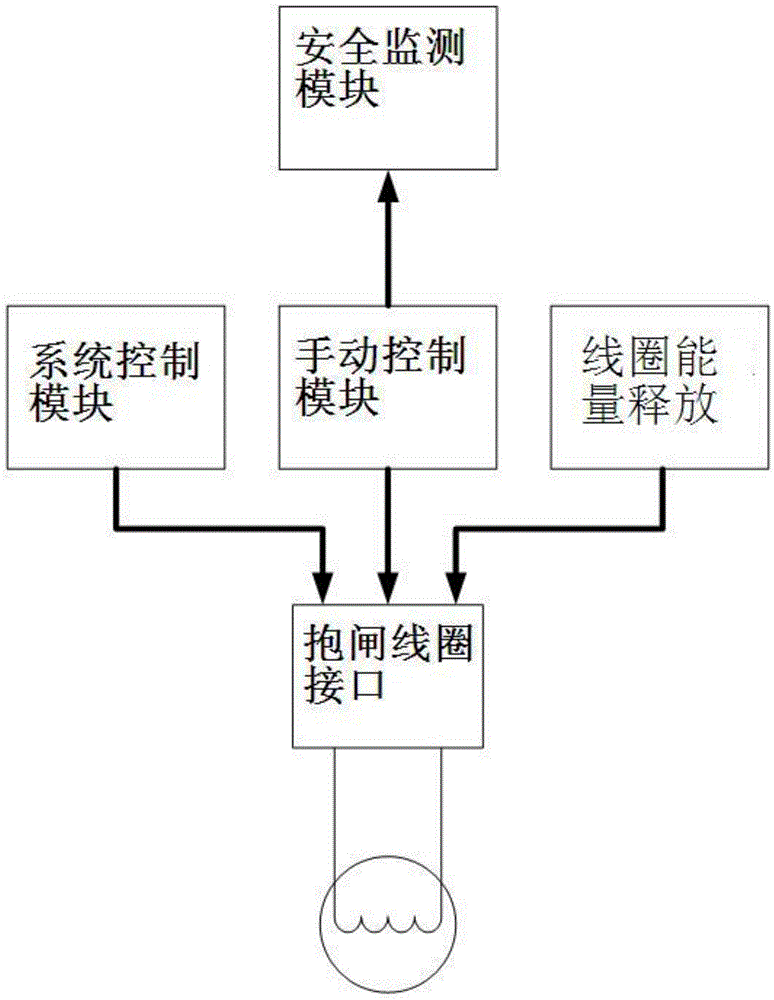

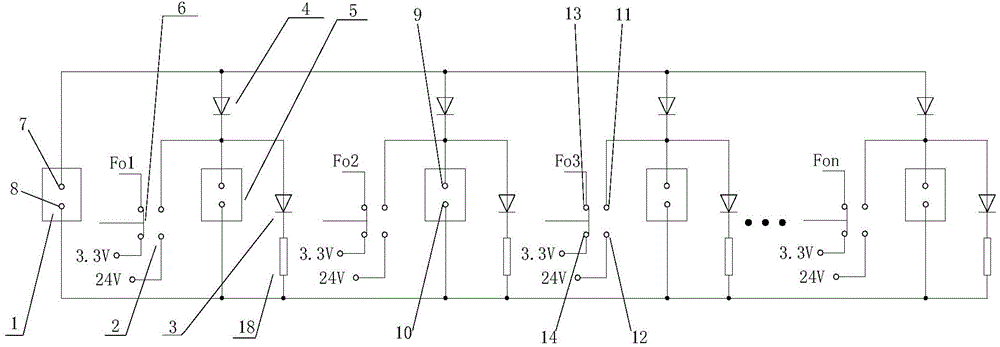

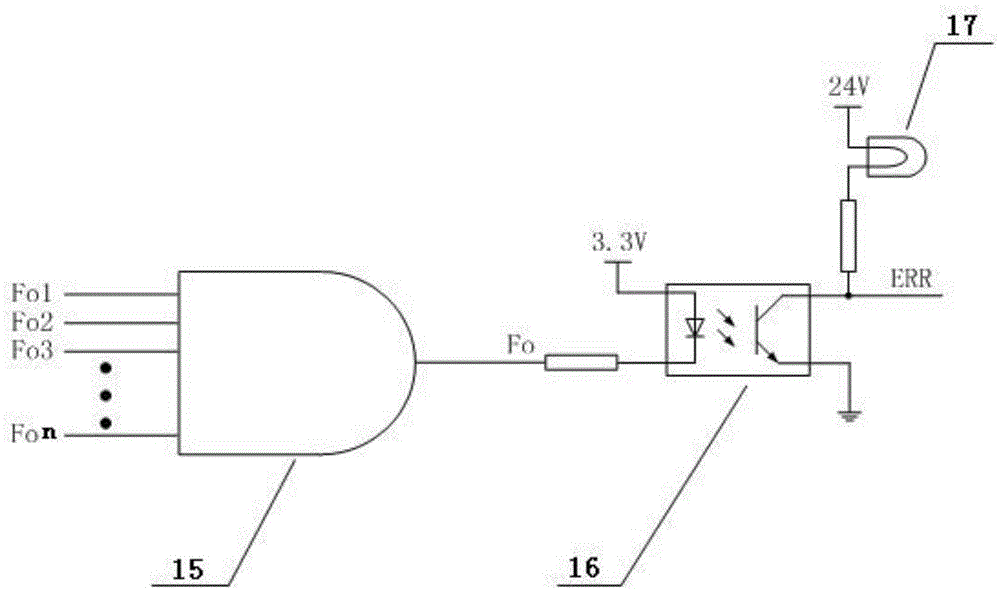

[0031] see figure 1 , this embodiment discloses an industrial robot motor brake controller with a safety monitoring device, including: a system control module for automatic control of the system, a manual control module for manually releasing the brake, and a Coil energy release module for response time, and safety detection module for monitoring whether the button fails; the system control module is set in the control cabinet of the robot; the manual control module is set on the robot; the system control module, manual control module and coil energy The release module is respectively connected to the brake coil interface 5 of the robot motor; the safety monitoring module is connected to the manual control module.

[0032] The system control module is used for system automatic control. When the industrial robot control system is running normally, the brake control signal given by the control cabinet is used to control the opening or locking of the brakes of the servo motors of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com