Integrated paper pulp molding equipment and method

A pulp molding and molding equipment technology, applied in textiles and papermaking, etc., can solve the problems of affecting quality, pulp molding rupture and damage, wet embryo deformation, etc., so as to improve product quality and production efficiency, reduce industrial accidents, and improve densification. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

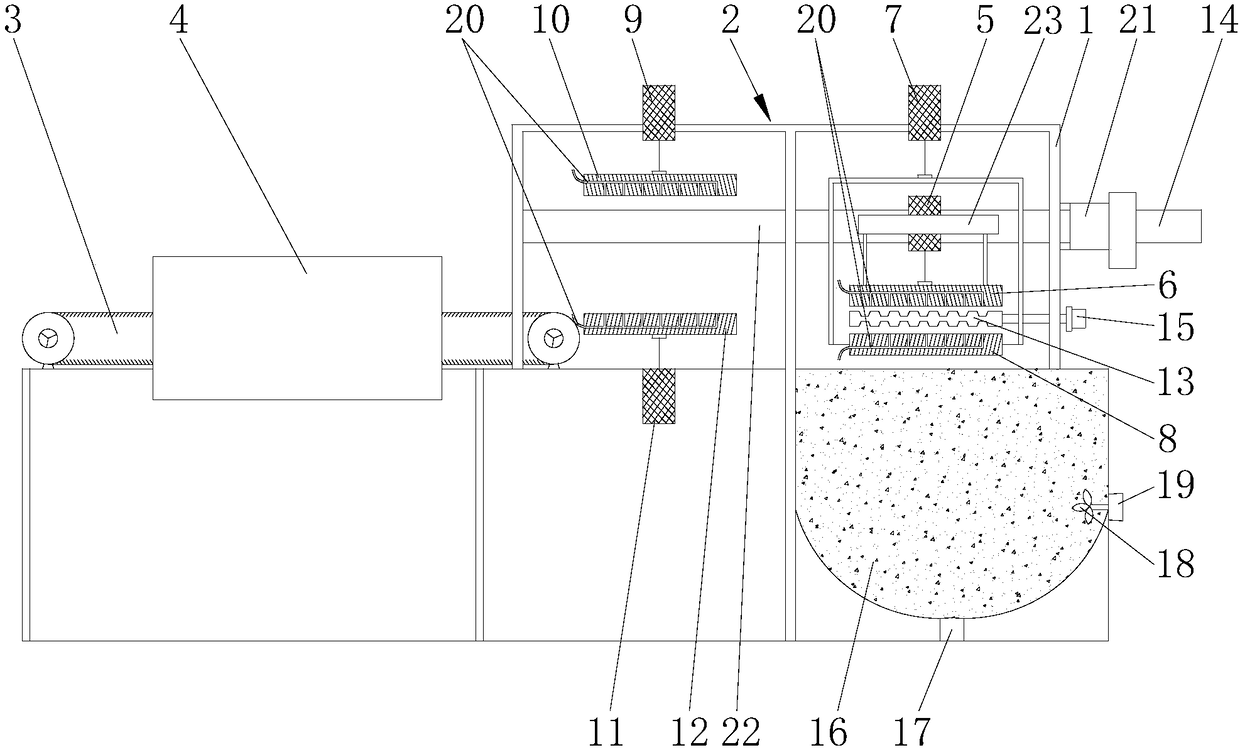

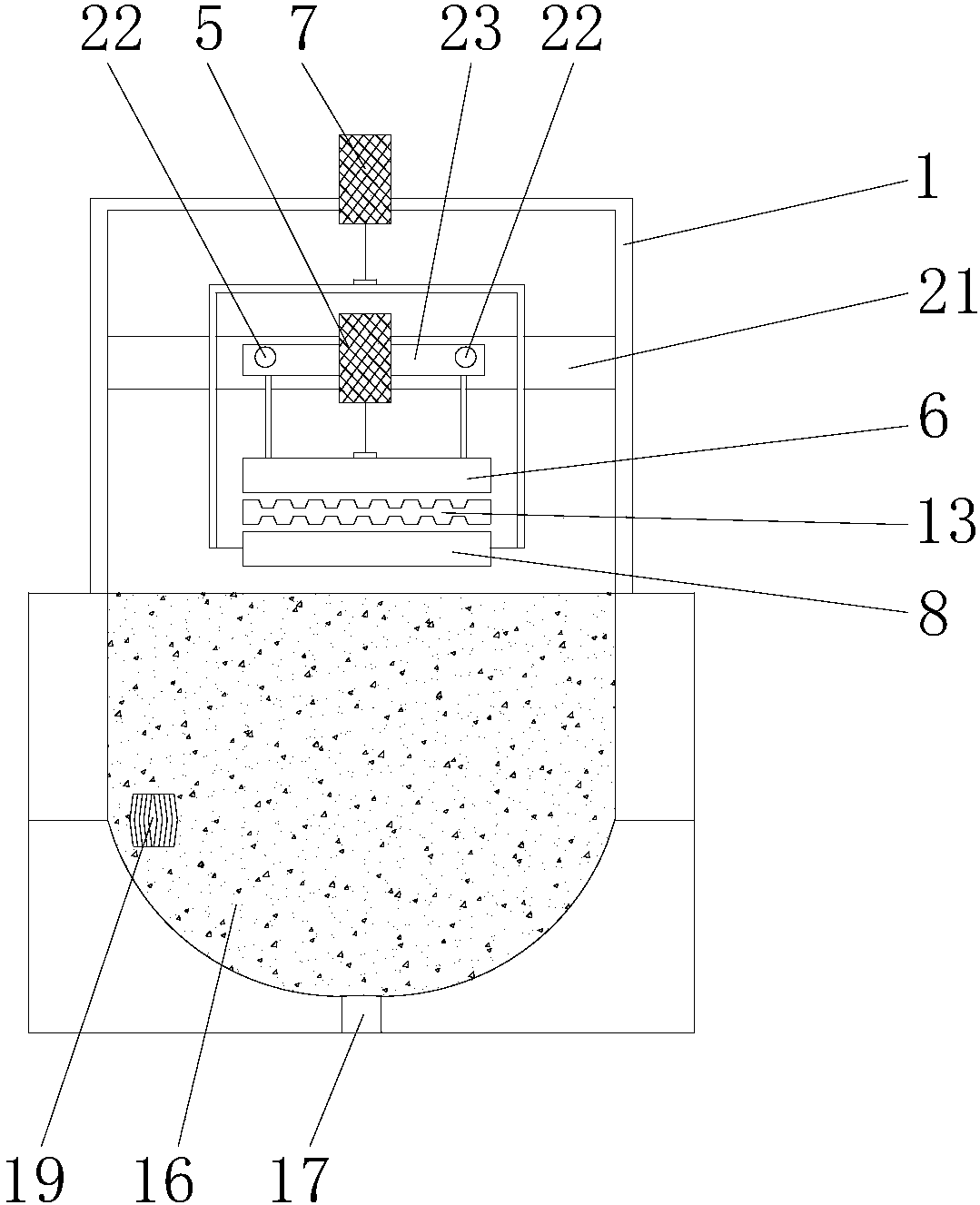

[0033] Embodiment 1 of the present invention: as Figure 1-Figure 3As shown, the integrated pulp molding equipment includes a frame 1, a molding mechanism 2, a conveying device 3, a drying mechanism 4 and a slurry tank 16, and the molding mechanism 2, conveying device 3 and drying mechanism 4 are all arranged on the frame 1, the conveying equipment 3 and the drying mechanism 4 are located on one side of the molding mechanism 2, the conveying equipment 3 is partly located in the drying mechanism 4, and the slurry pool 16 is located in the mold The bottom of molding mechanism 2. From the molding of the pulp in the molding mechanism 2 to the conveying equipment 3, the conveying equipment 3 is transported to the drying mechanism 4 for drying, which eliminates the process of manual handling in the prior art and reduces manpower. Ensure normal production, improve production efficiency, and make integrated preparation and drying possible. Integrated pulp molding equipment, the mold...

Embodiment 2

[0035] Embodiment 2: as Figure 1-Figure 3 As shown, the integrated pulp molding equipment includes a frame 1, a molding mechanism 2, a conveying device 3, a drying mechanism 4 and a slurry tank 16, and the molding mechanism 2, conveying device 3 and drying mechanism 4 are all arranged on the frame 1, the conveying equipment 3 and the drying mechanism 4 are located on one side of the molding mechanism 2, the conveying equipment 3 is partly located in the drying mechanism 4, and the slurry pool 16 is located in the mold The bottom of molding mechanism 2. From the molding of the pulp in the molding mechanism 2 to the conveying equipment 3, the conveying equipment 3 is transported to the drying mechanism 4 for drying, which eliminates the process of manual handling in the prior art and reduces manpower. Ensure normal production, improve production efficiency, and make integrated preparation and drying possible. The lower half of the slurry pool 16 is a hemisphere, the bottom of...

Embodiment 3

[0036] Embodiment 3: as Figure 1-Figure 3 As shown, the integrated pulp molding method adopts the above-mentioned integrated pulp molding equipment, including the following steps:

[0037] S1, after beating in the pulping workshop, the slurry is transported to the slurry pool 16 through the inlet and outlet port 17;

[0038] S2, the first horizontal driving device 14 drives the slurry suction upper mold support 23 to move along the guide rail 22, and then drives the slurry suction upper mold 6 to move to a position opposite to the slurry suction lower mold 8;

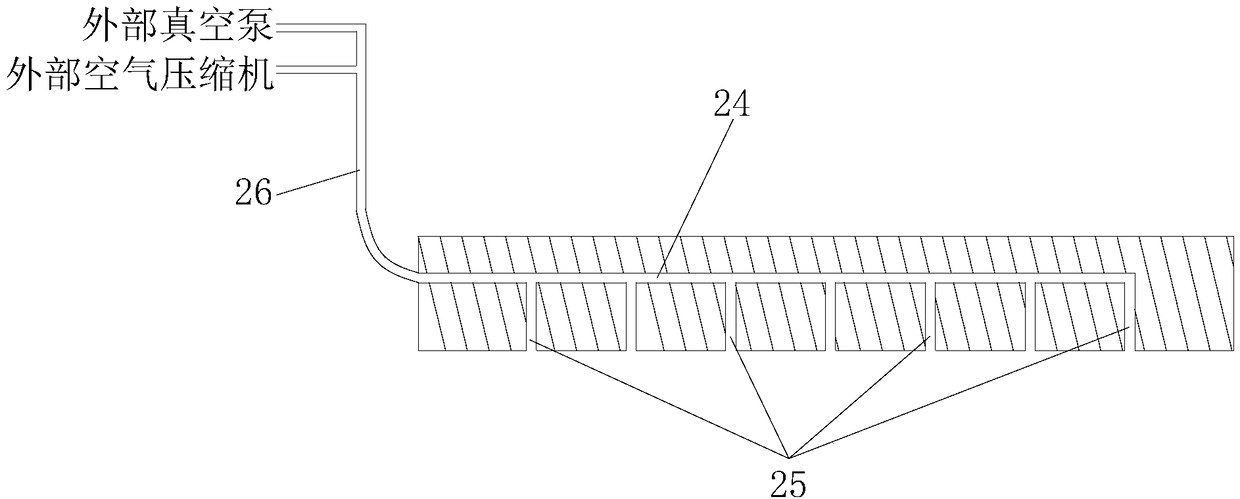

[0039] S3, the first lifting device 5 drives the slurry suction upper mold 6 down to the slurry pool 16, and the second lifting device 7 drives the slurry suction lower mold 8 down to the slurry pool 16, and the slurry suction upper mold 6 and the slurry suction lower mold 8 is covered with slurry, the first lifting device 5 drives the slurry suction upper mold 6 to rise, and the second lifting device 7 drives the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com