Rotating-disc type automatic feeding-discharging machine

An automatic loading and unloading machine technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increasing production costs, low operating efficiency, single function, etc., to improve production efficiency, improve safety, continuous good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

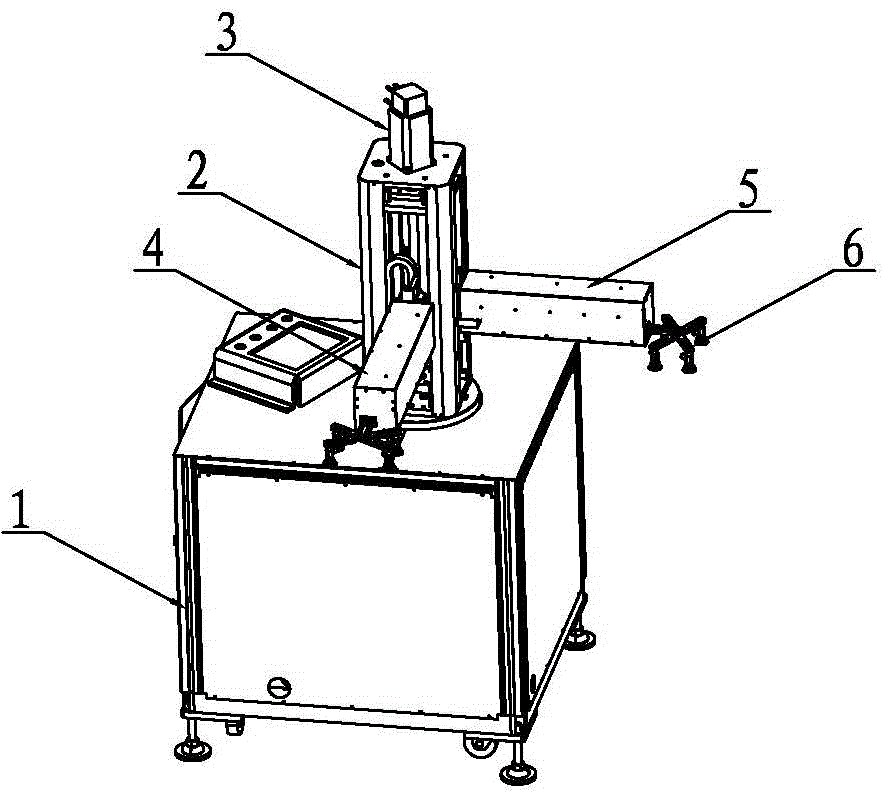

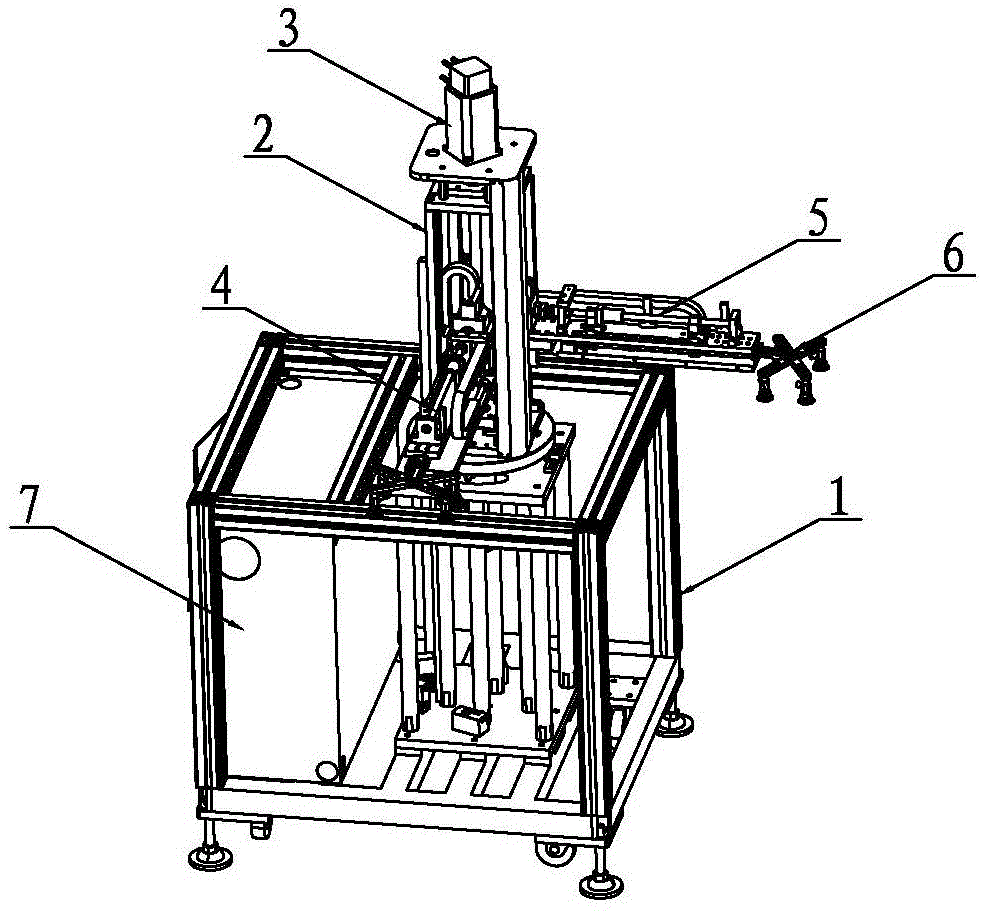

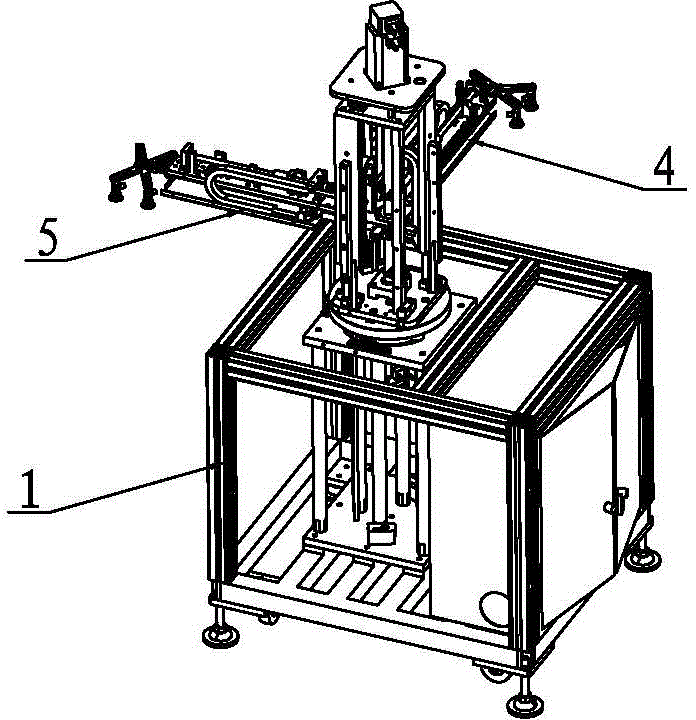

[0034] see Figure 1 to Figure 14, in order to achieve the above object, a turntable type automatic loading and unloading machine of the present invention includes a frame table 1 and a first servo motor 11, and the frame table 1 is provided with a transmission connection with the first servo motor 11 The roulette 12, the frame table 1 is also provided with a support frame 13 for fixing the first servo motor 11, the top of the roulette 12 is connected with a fixed frame 2, and the fixed frame 2 is provided with a lifting mechanism 3, The lifting mechanism 3 is connected with a first telescopic arm 4 and a second telescopic arm 5, and the first telescopic arm 4 and the second telescopic arm 5 are all provided with a suction cup device 6 for loading or unloading, and the frame Table 1 is also provided with a control device 7 electrically connected with the first servo motor 11, lifting mechanism 3, first telescopic arm 4, second telescopic arm 5 and suction cup device 6; the wor...

Embodiment 2

[0044] see Figure 15The difference between this embodiment and Embodiment 1 is that the first telescopic arm 4 includes a drive cylinder 48 connected to the control device 7, a fixed arm 42 and an extension arm 43, and the upper part of the fixed arm 42 is provided with Guide slot 45, the extension arm 43 is provided with a guide rail 46 that is matched with the guide slot 45, the inner end of the extension arm 43 is connected to the drive cylinder 48, and the suction cup device 6 is arranged on the extension The extended end of the arm 43. The driving cylinder 48 is connected with a solenoid valve, and the solenoid valve is electrically connected to the PCB control circuit board 71. When the first telescopic arm 4 is working, the driving cylinder 48 pushes the extension arm 43, and the extension arm 43 drives the cylinder 48. Under the active force, it moves outward along the guide groove 45; at the same time, when shrinking, the driving cylinder 48 is recovered to drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com