Integral automatic packing and sealing code-spraying and piling production line

An automatic and stacking technology, applied in the field of integrated automatic packaging, sealing, spraying and stacking production lines, can solve the problems of low labor cost, long turnaround time, inability to achieve packaging, coding, sealing and stacking, etc. The effect of solving the high accident rate of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, further illustrate the present invention by embodiment:

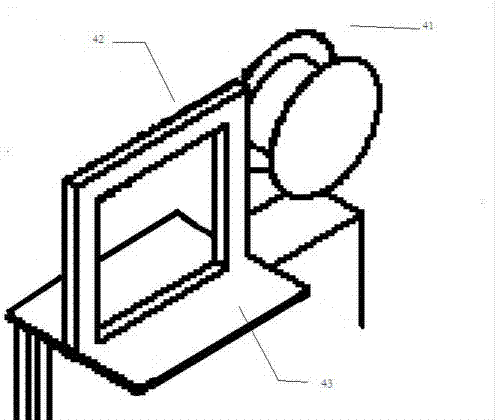

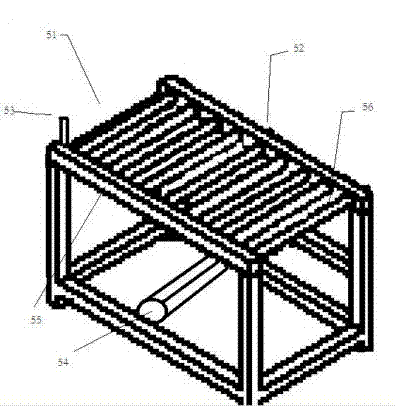

[0025] The integrated automatic packaging, sealing, spraying and stacking production line involved in the present invention, such as figure 1 As shown, there are 6 units in total, and the order of them is automatic coding unit 1 for medium cases, automatic packing unit 2, automatic folding and sealing unit 3, automatic packing unit 4, large case coding unit 5, stacking Unit 6. Each unit is connected with the PLC controller, and the signal acquisition and mechanical control are carried out through the PLC controller.

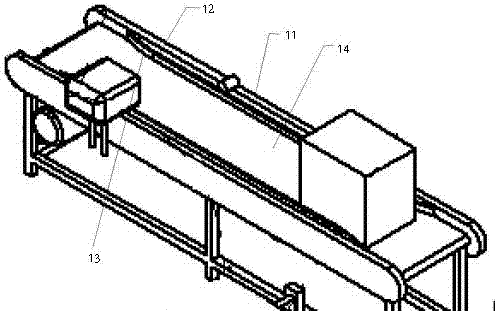

[0026] Such as figure 2 As shown, when the tundish box enters the conveyor belt 14 of the belt conveyor, the sensor located on the belt conveyor 14 senses the entry of the object, collects the signal and transmits the signal to the PLC controller, and the PLC controller transmits the information to the automatic Inkjet printer, when the middle bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com