Automatic industrial robot feeding and discharging production line for numerically-controlled machine tools

A technology of automatic loading and unloading, industrial robots, applied in metal processing and other directions, can solve the problems of unstable product processing accuracy and quality, the influence of the staff's operation ability, and the threat to the staff's health, etc., to improve the processing accuracy and quality, The effect of reducing labor costs and reducing work-related accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

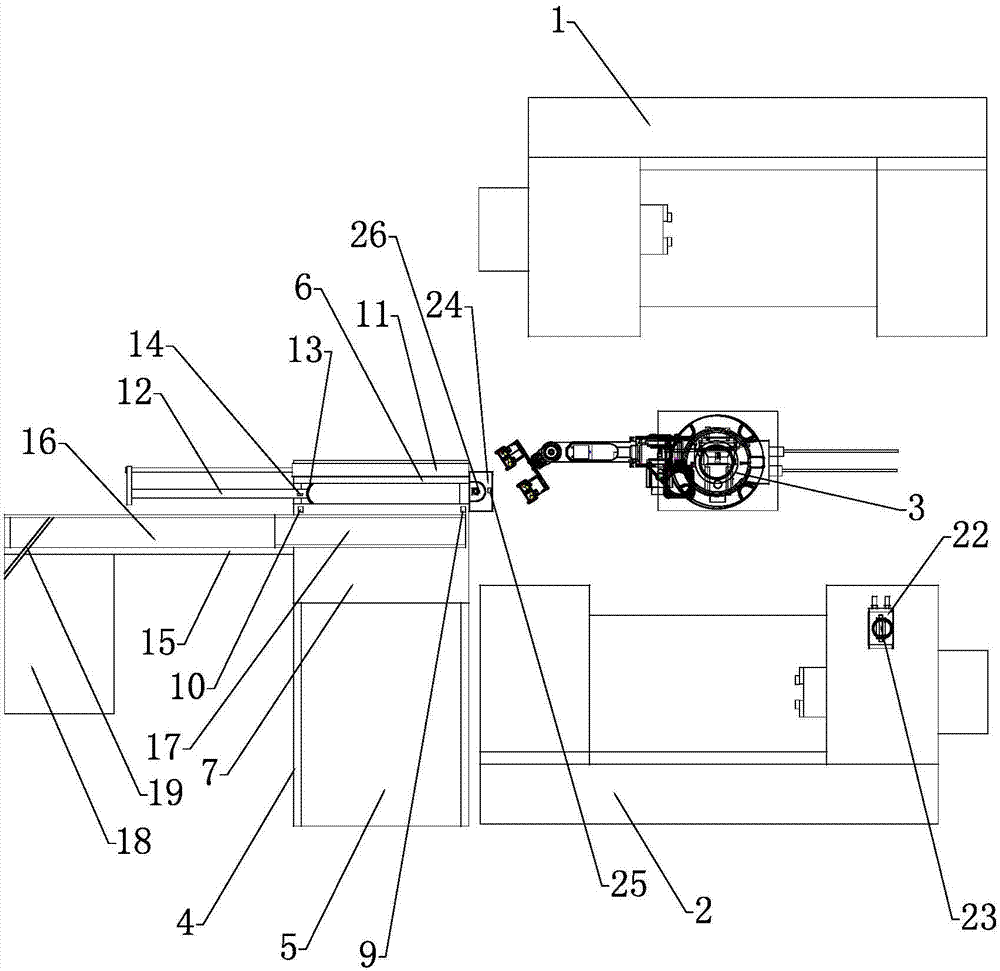

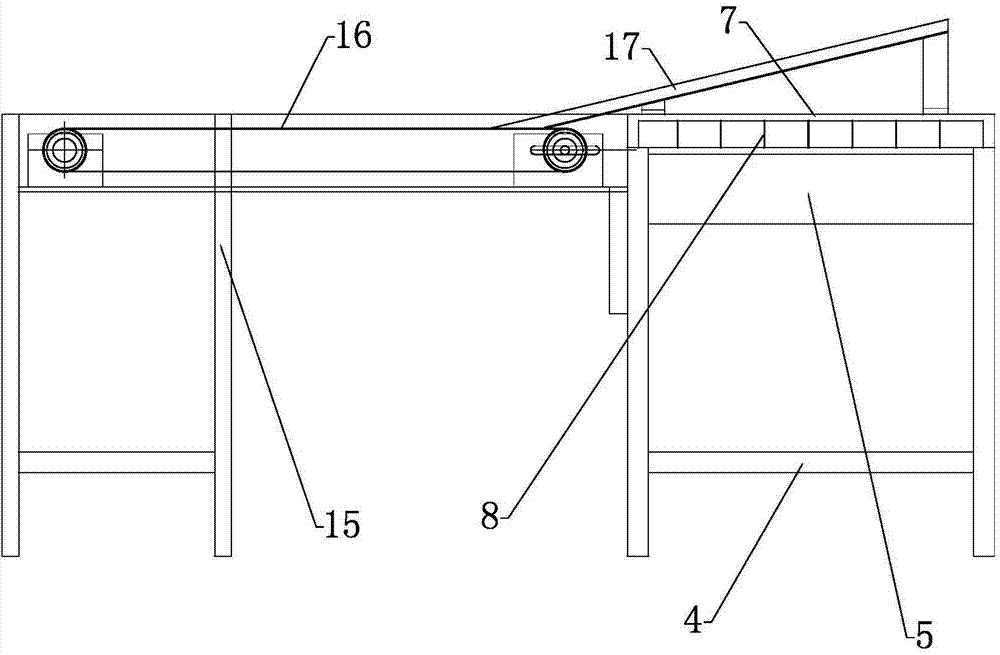

[0016] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

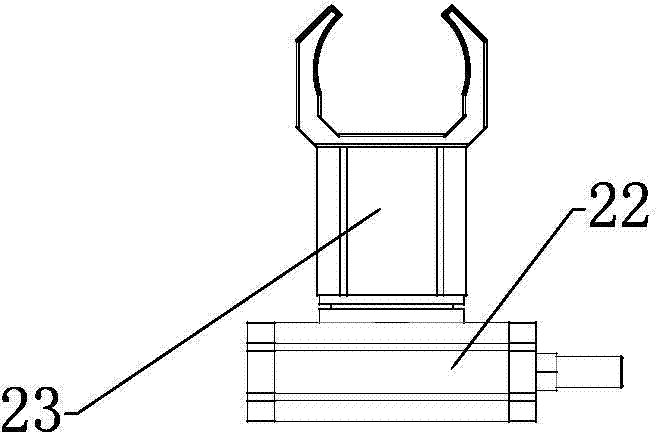

[0017] Such as Figure 1-4 As shown, an automatic loading and unloading production line of an industrial robot for a CNC machine tool includes an industrial robot 3 located between the first lathe 1 and the second lathe 2, and a feeding frame 4 is provided on one side of the second lathe 2, Feeding frame 4 is provided with feeding conveyer belt 5, is provided with workpiece baffle plate 6 near the position of feeding conveyer belt 5 discharging end on the feeding frame 4 of feeding conveyer belt 5 discharge end, in feeding conveying The top of the belt 5 is provided with a horizontally arranged material guide plate 7, and the both sides of the material guide plate 7 are connected with the feeding frame 4 on both sides of the feeding conveyor belt 5 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com