Vessel spraying robot

A spraying robot and robot technology, applied in the direction of spraying device, etc., can solve the problems of high wage cost, insufficient spraying of corners, uneven spraying, etc., achieve high degree of automation, high work efficiency, and reduce industrial accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

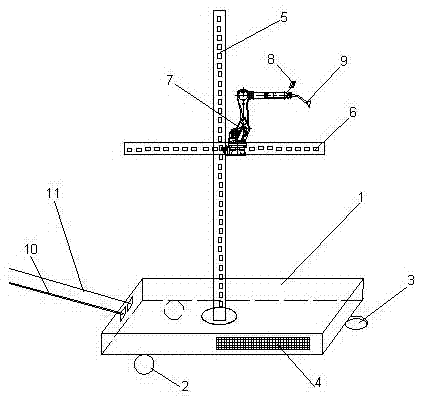

[0011] A ship spraying robot, the robot includes a platform 1, an electromagnetic adsorption wheel 2, a steering wheel 3, a receiving and executing system 4, a vertical lifting rod 5, a horizontal moving rod 6, a painting manipulator 7, a detection device 8 and a spray gun 9, the The electromagnetic adsorption wheel 2 and the steering wheel 3 are connected to the lower part of the platform 1, the receiving and executing system 4 is arranged in the platform 1, one end of the vertical lifting rod 5 is fixedly connected to the platform 1, and the horizontal moving rod 6 is connected to the vertical elevating rod 5, one end of the painting manipulator 7 is fixedly connected to the horizontal moving rod 6, the other end of the painting manipulator 7 is provided with a spray gun 9, and the detection device 8 is arranged on the paint spraying manipulator 7 at the rear of the spray gun 9 , the platform 1 is also provided with a power cord 10 and a functional interface 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com