Flat blank continuous casting closed-top technology for preventing steel liquid roof-falling

A technology for slab continuous casting and molten steel, which is applied in the field of casting technology of straight arc continuous casting machines, can solve the problems of low pulling speed, long time, high temperature of the tail casting billet, and reduced productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

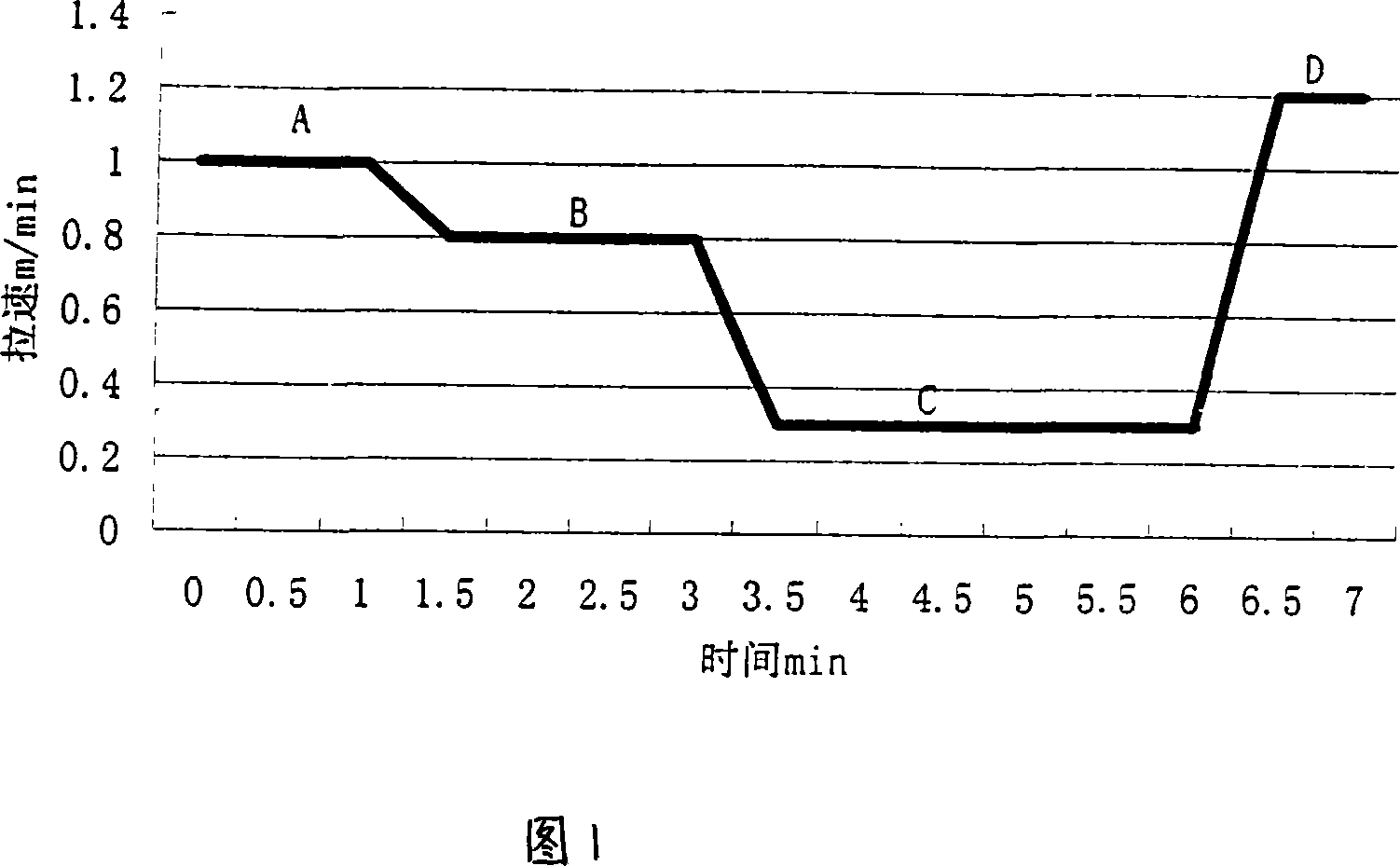

[0011] Example 1 The cast steel type is peritectic steel, the normal weight of the tundish is 30 tons, and the conventional casting speed is 1.0 m / min (marked A in the figure).

[0012] After the last furnace ladle is poured, when there is only 10t of molten steel left in the tundish, reduce the speed to 0.8m / min, and keep casting for 2 minutes (marked B in the figure), and then the captain will pull the casting speed to 0.3m / min , drive away the tundish car, maintain the pulling speed at 0.3m / min (mark C in the figure), remove the residue strips and water breaks on the molten steel surface in the crystallizer, and use a long oxygen pipe to fully stir the steel along the side. Liquid surface, after stirring, the length of the empty blank shell at the liquid surface must be ≥ 100mm, and then water cooling is carried out. During this period, the time is 3 minutes, and then the speed is increased to 1.2m / min (D mark in the figure) to pull the tail blank .

Embodiment 2

[0013] Example 2 The casting steel is weakly deoxidized steel, the normal weight of the tundish is 50 tons, and the typical casting speed is 1.4m / min.

[0014] After pouring the last furnace of ladle, when there is only 16 tons of molten steel left in the tundish, reduce the speed to 1.2m / min and keep casting for 3 minutes, then the captain will reduce the casting speed to 0.4m / min, drive away the tundish car, Maintain a casting speed of 0.4m / min, remove the residue strips and water breaks on the molten steel surface in the mold, insert 2 kg of aluminum strips into the molten steel in the mold, and use a long oxygen tube to fully stir the molten steel surface along the side, stirring After the completion, the length of the empty billet shell at the liquid level is guaranteed to be more than 100mm, and then it is cooled with water. The time during this period is 3 minutes, and then the speed is increased to 1.6m / min to pull the tail billet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com