Intellectualized material cutting-off machine

A cutting machine and cutting mechanism technology, used in shearing devices, accessories of shearing machines, shearing machine equipment, etc., can solve problems such as inability to process, scratch surfaces, deformation, etc., to improve safety and prevent industrial accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

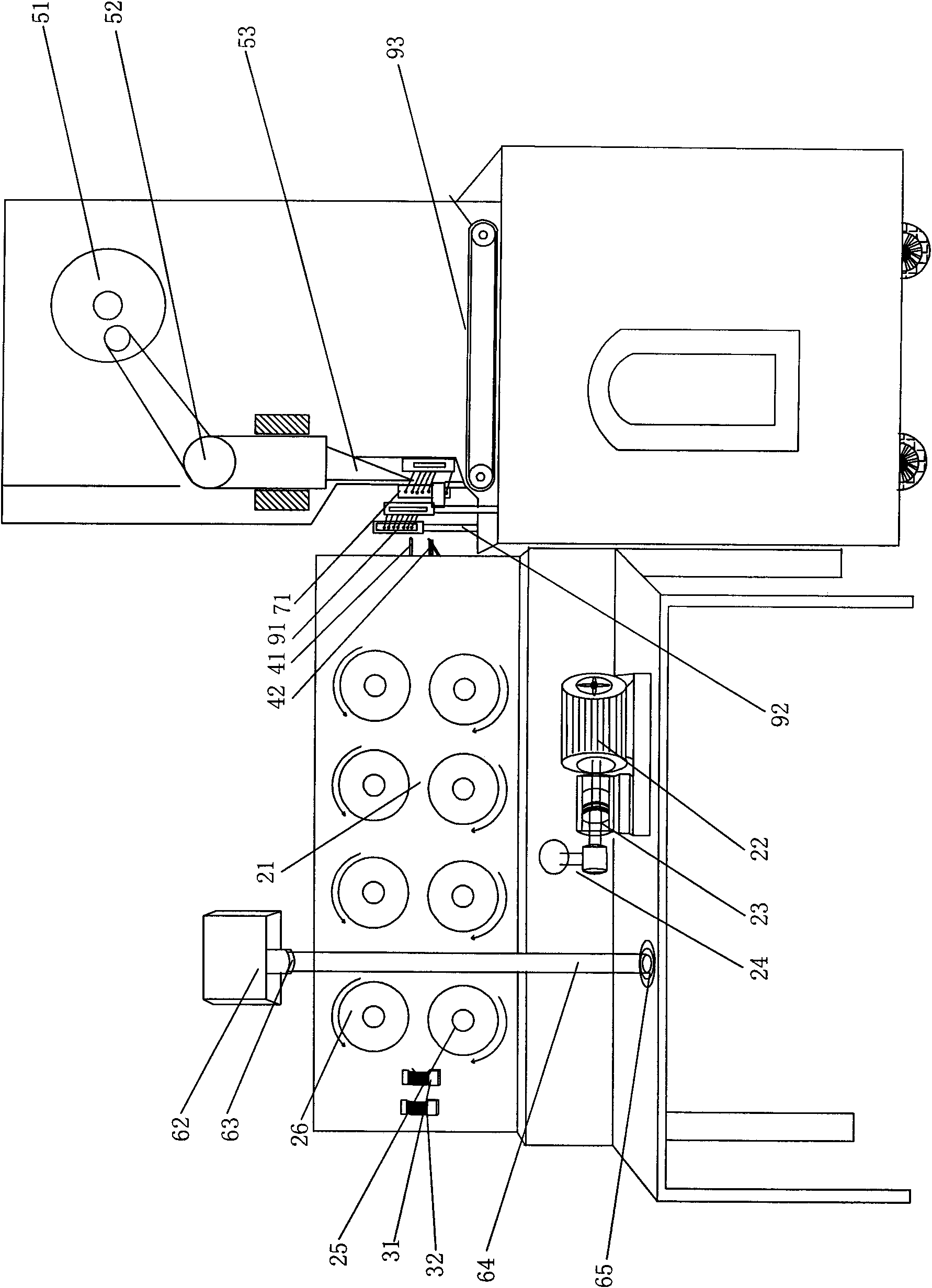

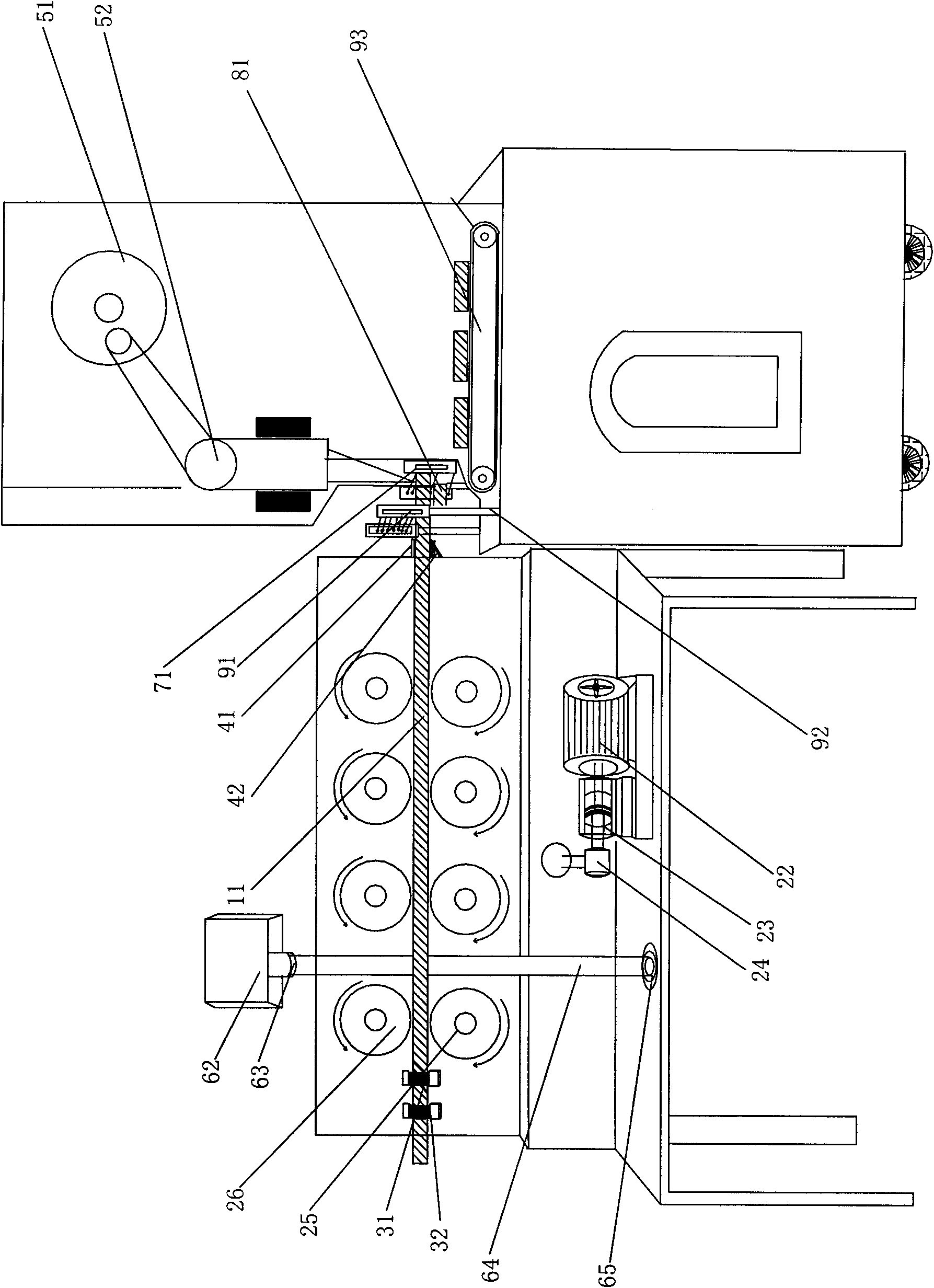

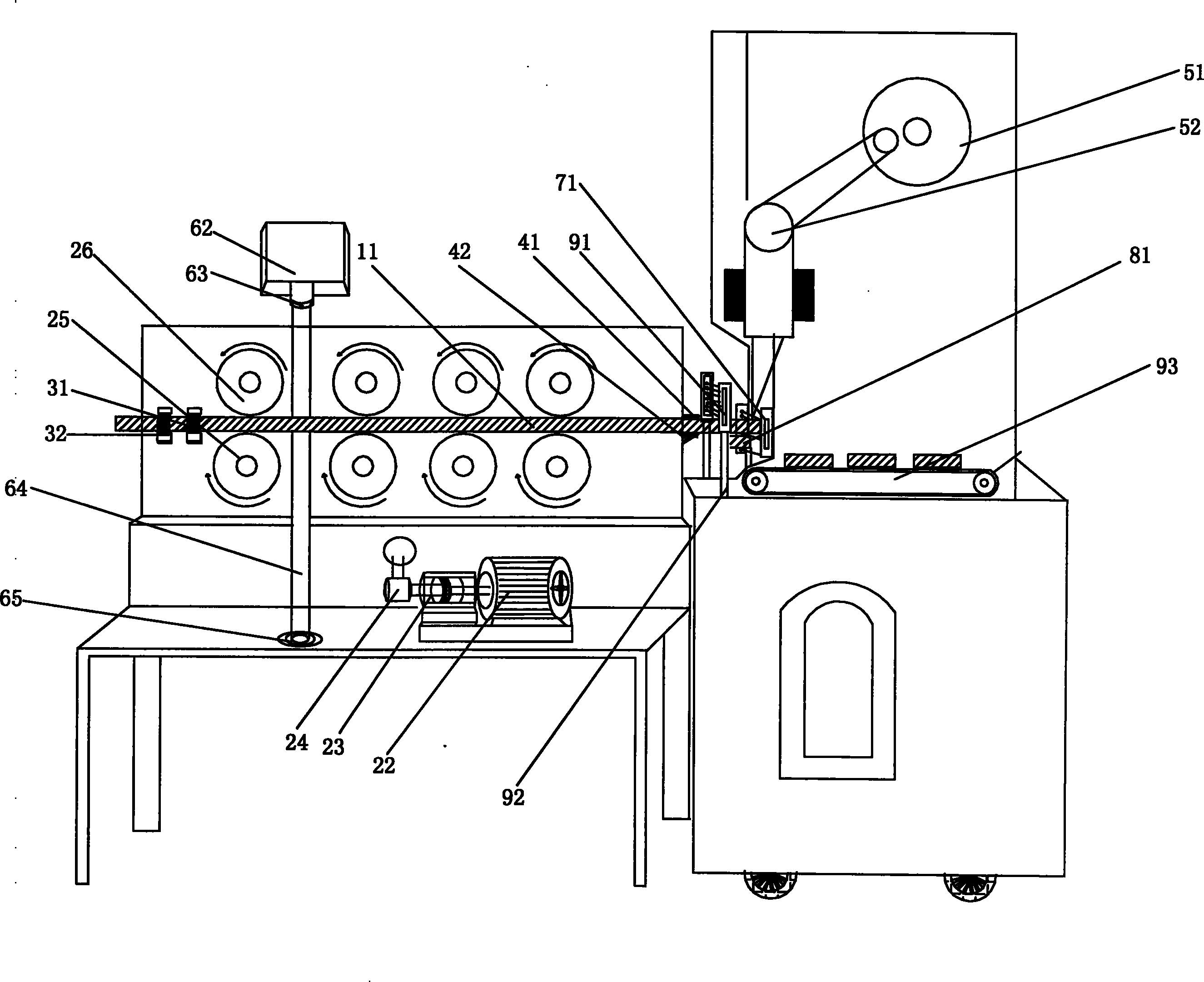

[0021] Such as figure 1 and figure 2 As shown, an intelligent material cutting machine includes a conveying mechanism, a cutting mechanism and a control mechanism. The conveying mechanism is used to convey the material 11 so that it moves along the conveying channel 21; the cutting mechanism is used to cut off the material 11 passing through the conveying channel 21; the control mechanism is used to control the action of the conveying mechanism and the cutting mechanism, reasonable Adjust the material conveying speed and cutting speed, so as to realize the automatic operation of the cutting machine. The control mechanism is industrial computer, single-chip microcomputer or PLC. The conveying mechanism is located upstream, and the cutting mechanism is located downstream. The materials are output in an orderly manner through the conveying mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com