Method and device for controlling inverter compressor

A frequency conversion compressor and control method technology, applied in the field of heating and ventilation, can solve the problems of not being able to adjust the frequency conversion speed according to the actual situation, and unable to realize a fast, energy-saving and stable frequency conversion process at the same time, so as to shorten the cooling time, ensure the stability, The effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

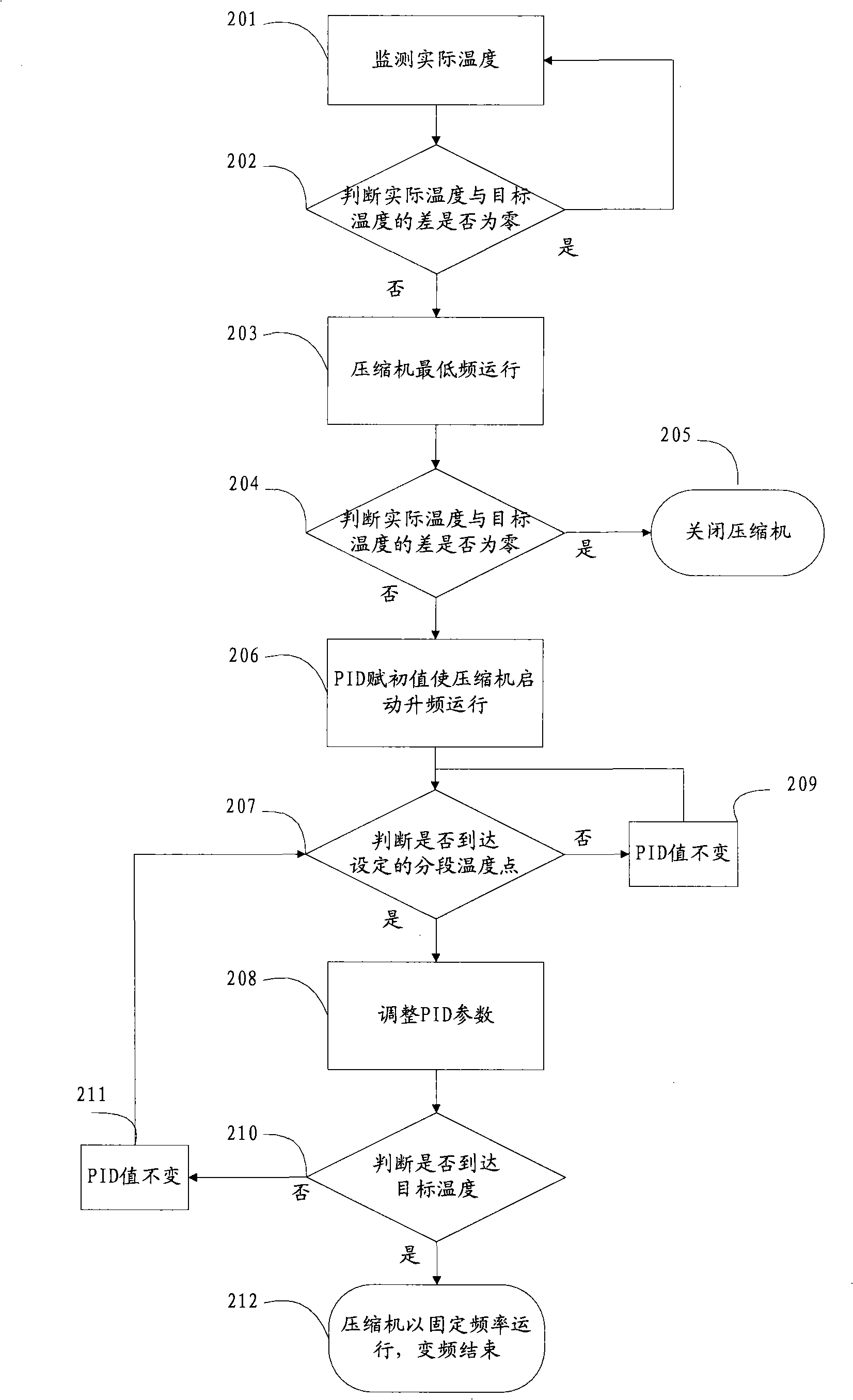

[0035] This embodiment combines figure 2 , image 3 with Figure 4 A specific implementation manner of the control method of the frequency conversion compressor of the present invention is disclosed.

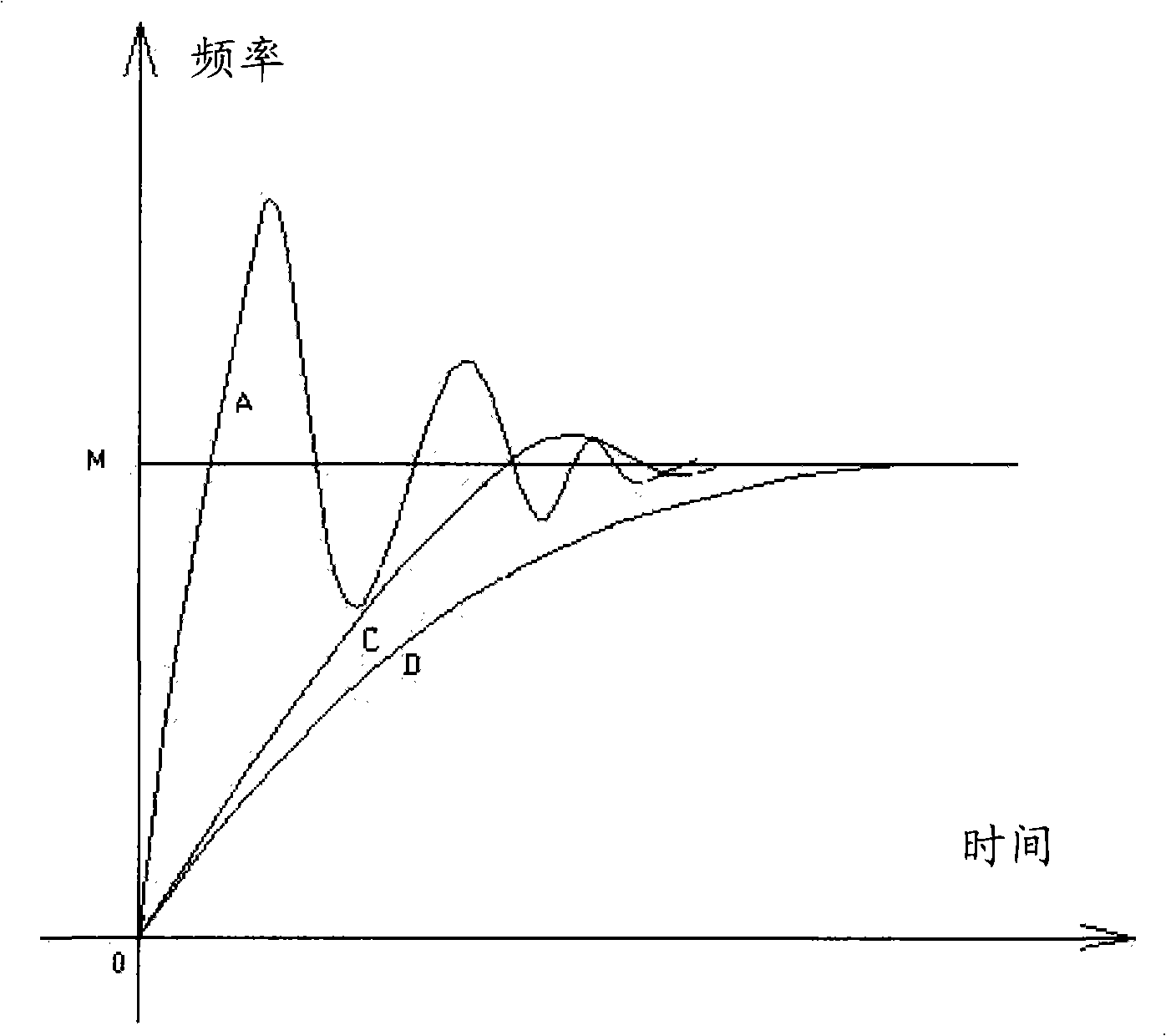

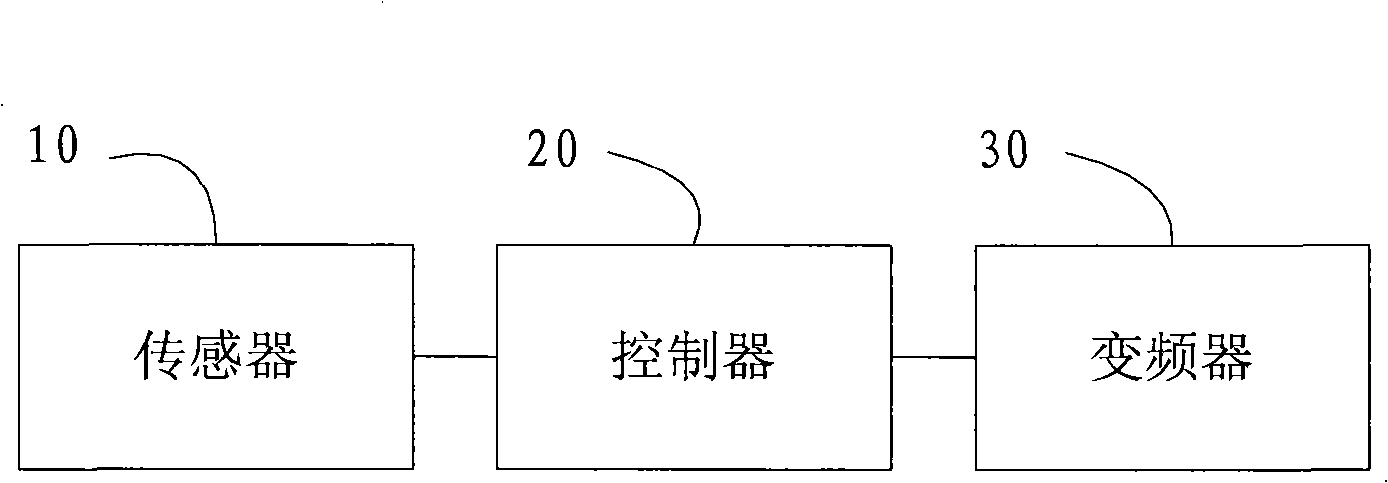

[0036] figure 2 It is a schematic diagram of the control device of the frequency conversion compressor in this embodiment, image 3 It is a flow chart of the control method of the inverter compressor in this embodiment, Figure 4 It is a schematic diagram of the frequency conversion process of the compressor in this embodiment.

[0037] The refrigerant used in the frequency conversion magnetic levitation centrifugal central air-conditioning unit is a commonly used refrigerant in the refrigeration industry. The refrigerant is water or other fluids. The unit first cools the refrigerant by compressing the refrigerant, and then circulates the refrigerant indoors to lower the room temperature, for example With water as the refrigerant, refer to figure 2 As shown, the variabl...

Embodiment 2

[0047] This embodiment combines the attached Figure 5-Figure 7 Another specific implementation of the variable frequency compressor control method is disclosed. The difference from Embodiment 1 is that after the PID parameters are adjusted in sections, the controller detects in real time whether the rate of temperature change exceeds the limit value, and if so, reassigns values to the PID parameters until the rate of temperature change is lower than the limit value.

[0048] Figure 5 It is a schematic diagram of the control device of the frequency conversion compressor in this embodiment, Image 6 It is a flow chart of the control method of the inverter compressor in this embodiment, Figure 7 It is a schematic diagram of the frequency conversion process of the compressor in this embodiment.

[0049] refer to Figure 5 As shown, the variable frequency compressor control device includes: a sensor 11, a controller 21 and a frequency converter 31; the sensor 11 in the uni...

Embodiment 3

[0061] This embodiment combines the attached Figure 8 with Figure 9 Another implementation of the variable frequency compressor control method is disclosed. During the cooling process, if the actual temperature is lower than the target temperature, that is, the actual temperature is overshooting relative to the target temperature, the inverter compressor control method and device described in this embodiment judge whether the overshoot is overshooting, and then start the frequency reduction adjustment process.

[0062] Figure 8 It is a schematic diagram of the control device of the frequency conversion compressor in this embodiment, Figure 9 It is a flow chart of the control method of the inverter compressor in this embodiment.

[0063] refer to Figure 8 As shown, the control device of the variable frequency compressor includes: a sensor 12, a controller 22 and a frequency converter 32; wherein, the sensor 12 is used to monitor the outlet water temperature in real tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com