Closed-loop control method and closed-loop control device for width of adhesive tape

A closed-loop control and rubber strip technology, applied in the field of tire manufacturing, can solve the problems of many external conditions, high complexity, complex algorithms, etc., to avoid signal interference, stable acquisition and control, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

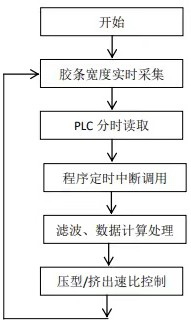

[0041] Such as figure 1 Shown, a kind of rubber strip width closed-loop control method, comprises the following steps:

[0042] S1, obtaining the real-time width value of the rubber strip; further, in S1, when obtaining the width value of the rubber strip, the following steps are included: obtaining the position pixel where the infrared light source is blocked by the rubber strip and reflected on the reflector; calculate according to the position pixel The width value of the rubber strip can be specifically, according to the number of pixels between the counting position pixel and the relative two sides, it can be used as the real-time width value of the rubber strip. In this application, the infrared width measuring sensor is used to directly output the analog quantity of the measurement signal After converting the analog quantity to digital, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com