Electronic component cooling apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

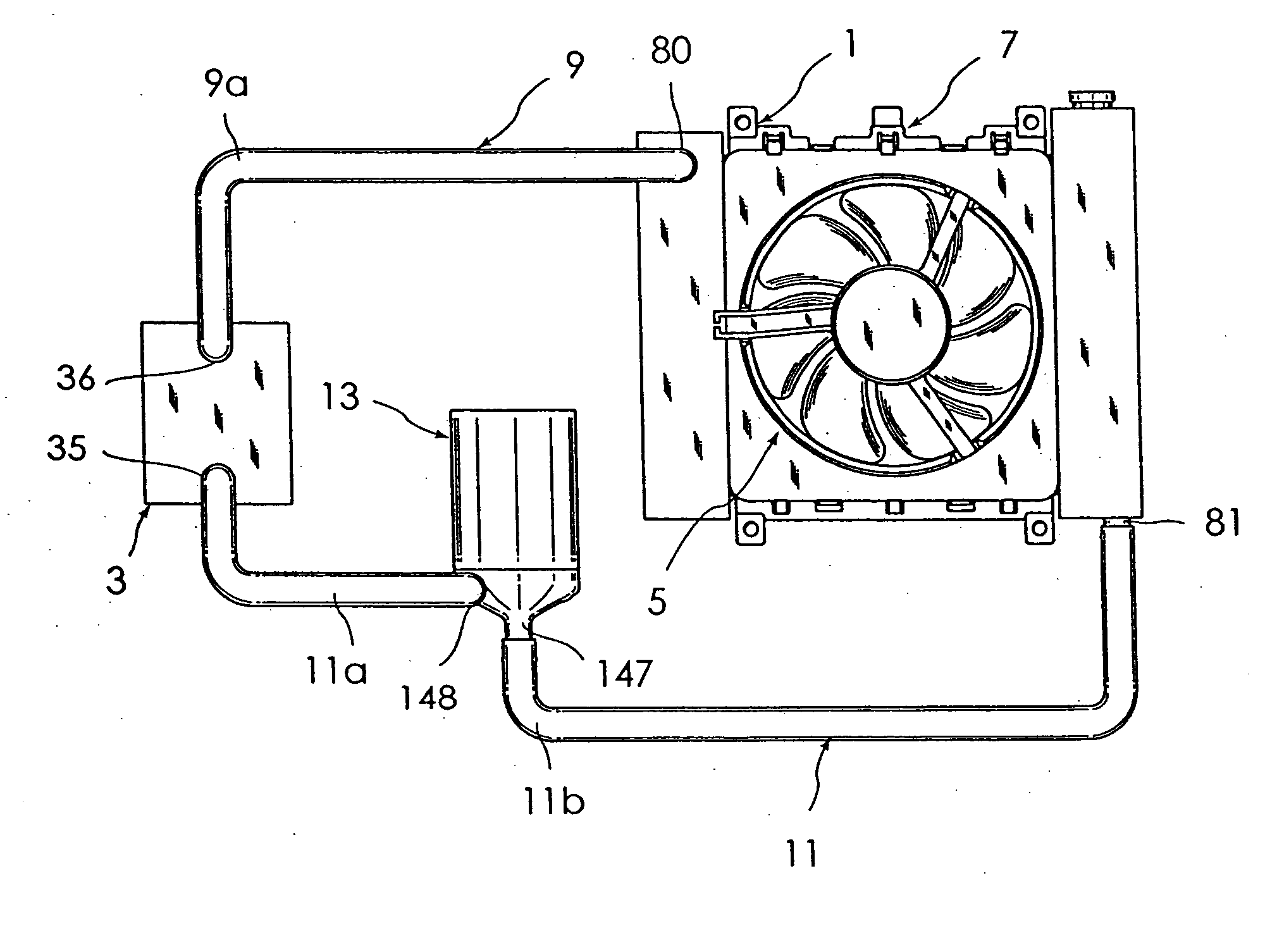

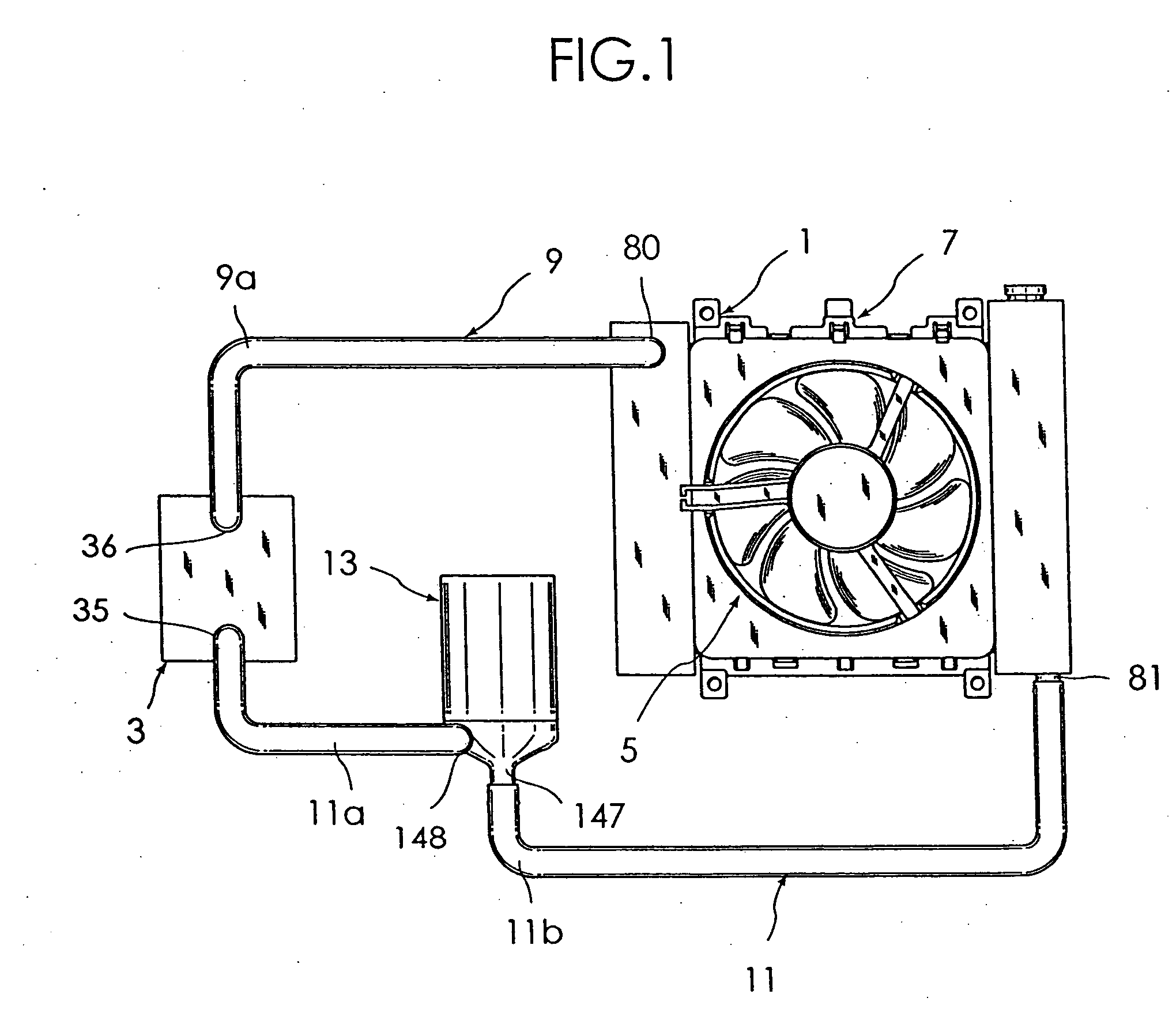

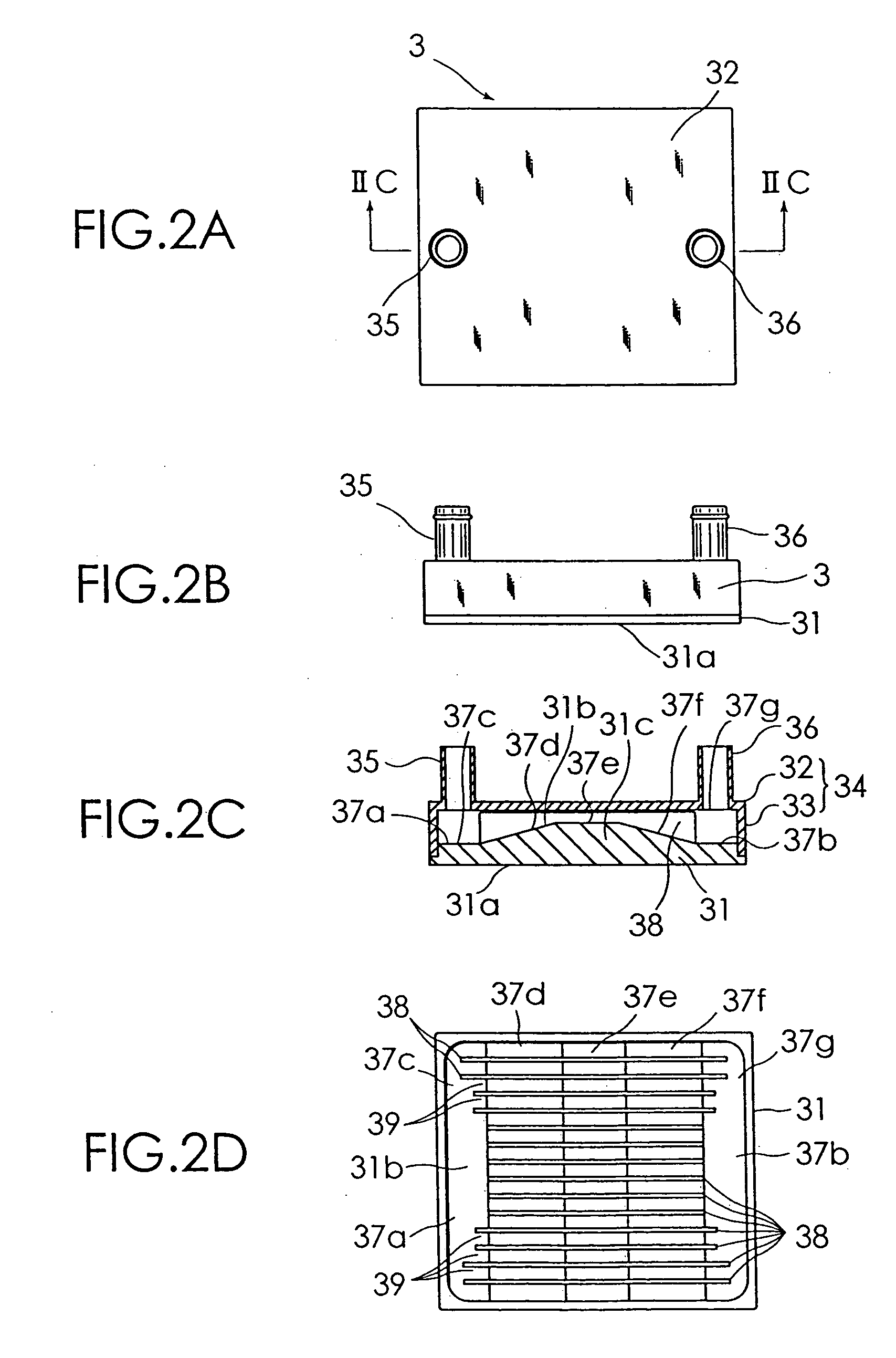

[0049] Now, by referring to the accompanying drawings, one embodiment of an electronic component cooling apparatus according to the present invention will be described in detail. FIG. 1 is a plan view showing a construction of embodiment of an electronic component cooling apparatus 1 according to the present invention. The electronic component cooling apparatus 1 has a water-cooled heat sink 3 having a coolant path therein, a radiator 7 cooled by a motor-driven fan 5, and a motor-driven pump 13 for giving a moving energy to the coolant in order to circulate the coolant between the heat sink 3 and the radiator 7.

[0050] The heat sink 3 has an electronic component mounting surface for mounting electronic components, such as a CPU, to be cooled. Also the heat sink 3 has a coolant path, with a coolant inlet (a cylindrical member 35) and a coolant outlet (a cylindrical member 36), through which a liquid coolant flows to forcibly cool the electronic component mounting surface. The radiato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com