Flaky rare earth permanent magnet powder and preparation method thereof

A rare earth permanent magnet, flake technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of powder particle size distribution not specified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

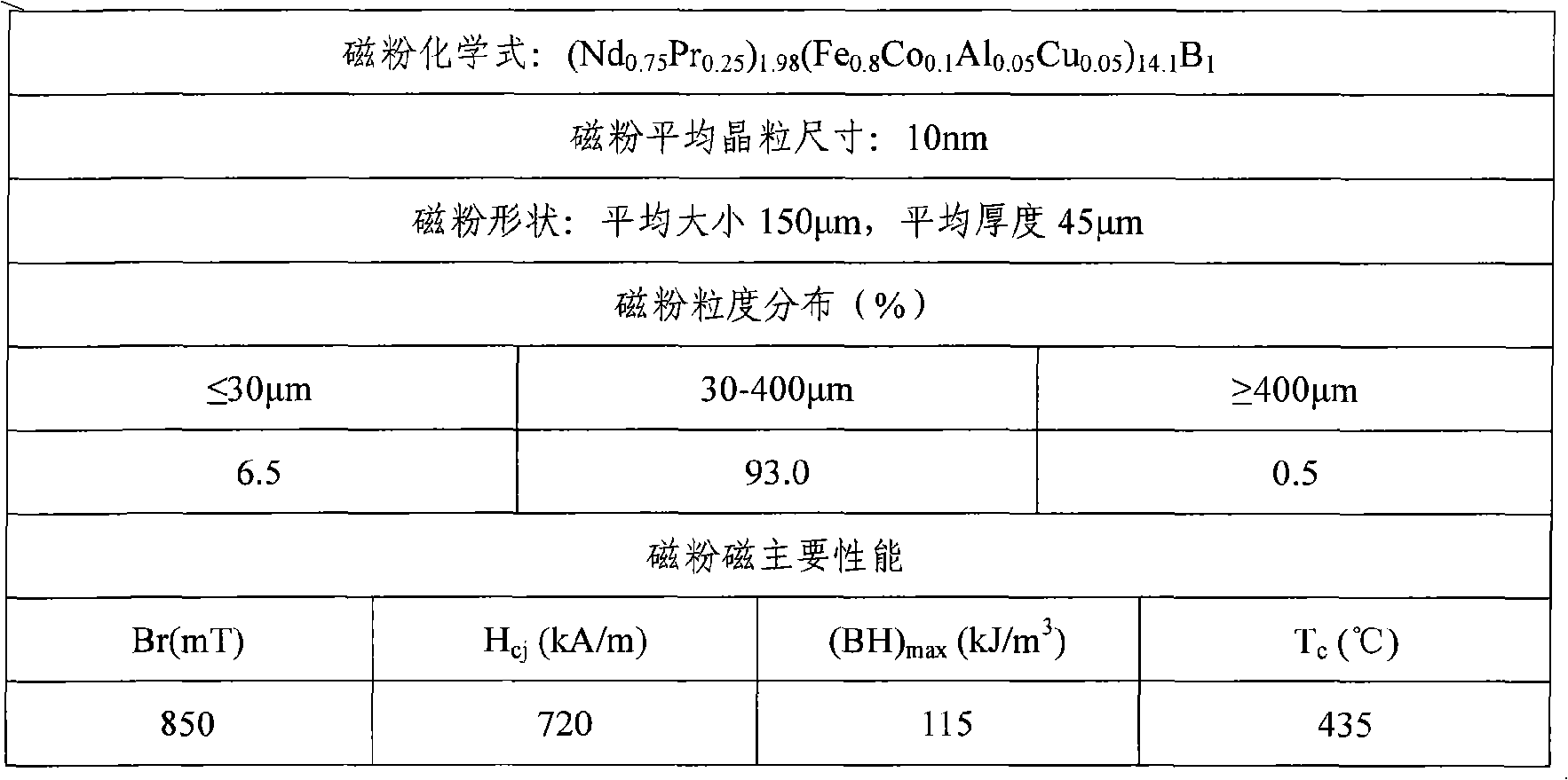

Embodiment 1

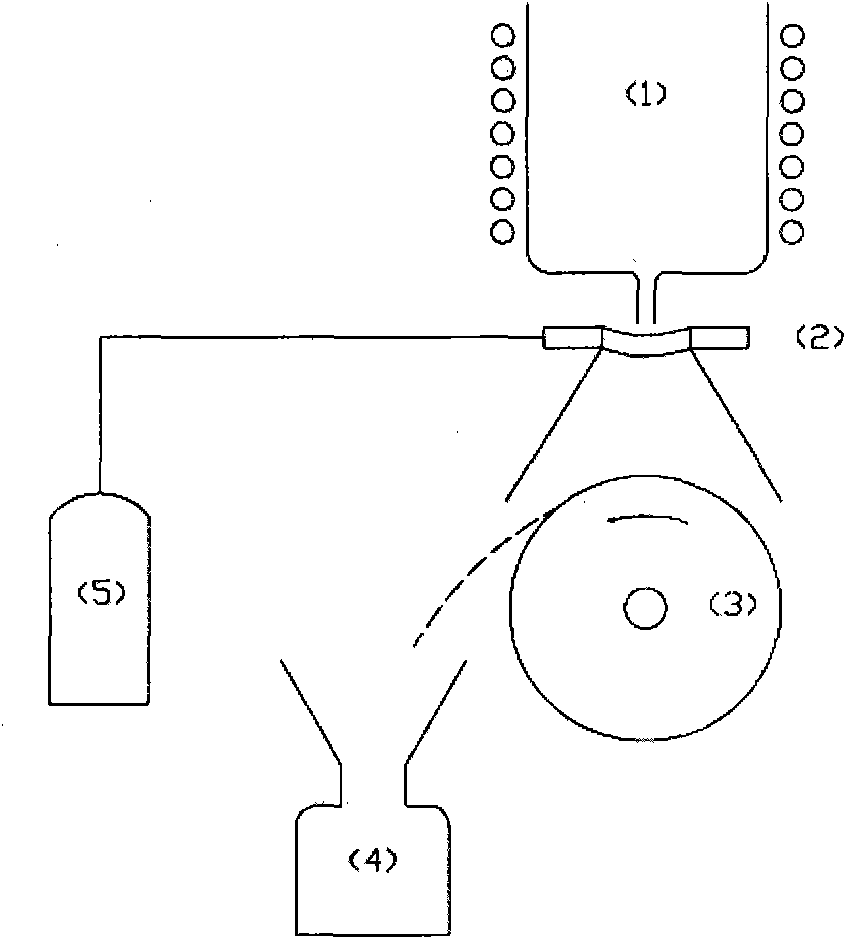

[0037] The preparation method of the magnetic powder in this example is as follows: according to the pre-designed components, a certain proportion of iron, cobalt, aluminum, copper, praseodymium-neodymium alloy, and boron-iron alloy is put into the crucible, and the bottom of the crucible has an opening of Φ1.5mm, and melted And during refining, the opening is blocked with a special stopper rod. Use intermediate frequency smelting to melt, wait until all metals or alloys are fully melted and then refine for 5 minutes. After refining, adjust the intermediate frequency power to keep the temperature of molten steel at a certain temperature, and then pull up the stopper rod to let the molten steel flow from the crucible Opening at the bottom to flow out. The molten steel flowing out is fully atomized through the ring-shaped high-pressure gas (Ar gas) nozzle to form a droplet flow, which is directly sprayed onto the high-speed rotating water-cooled copper wheel for rapid quenching ...

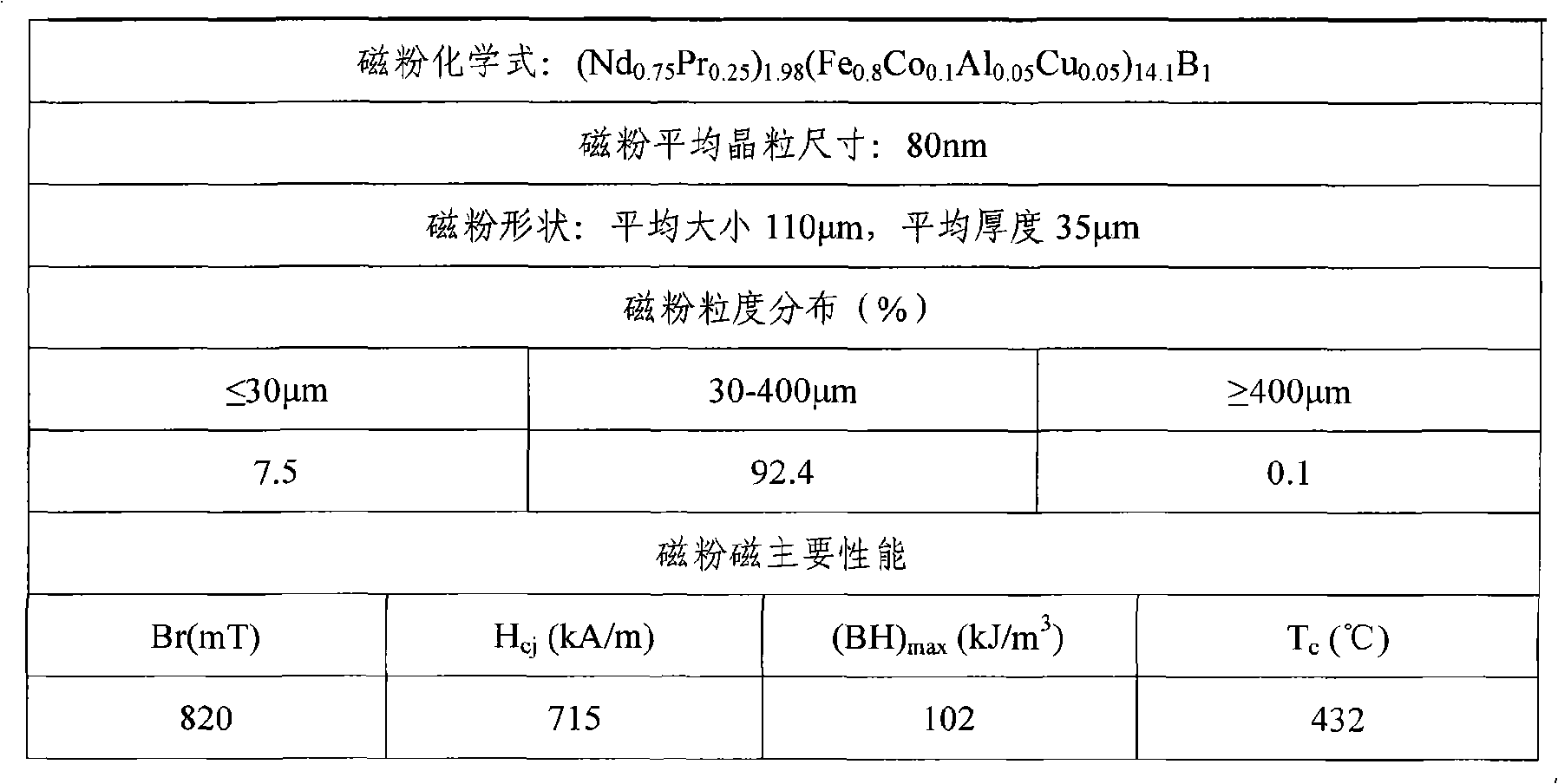

Embodiment 2

[0041] The preparation method of the magnetic powder in this example is as follows: according to the same composition ratio as in Example 1, a certain proportion of iron, cobalt, aluminum, copper, praseodymium-neodymium alloy, and boron-iron alloy are put into the crucible, and the bottom of the crucible has a Φ1.0mm The opening of the furnace is blocked by a special stopper rod during melting and refining. Use intermediate frequency smelting to melt, wait until all metals or alloys are fully melted and then refine for 5 minutes. After refining, adjust the intermediate frequency power to keep the temperature of molten steel at a certain temperature, and then pull up the stopper rod to let the molten steel flow from the crucible Opening at the bottom to flow out. The molten steel flowing out is fully atomized through the ring-shaped high-pressure gas (Ar gas) nozzle to form a droplet flow, which is directly sprayed onto the high-speed rotating water-cooled copper wheel for rapi...

Embodiment 3

[0045] The preparation method of the magnetic powder in this example is as follows: according to the same composition ratio as in Example 1, a certain proportion of iron, cobalt, aluminum, copper, praseodymium-neodymium alloy, and boron-iron alloy are put into the crucible, and the bottom of the crucible has a Φ2.0mm The opening of the furnace is blocked by a special stopper rod during melting and refining. Use intermediate frequency smelting to melt, wait until all metals or alloys are fully melted and then refine for 5 minutes. After refining, adjust the intermediate frequency power to keep the temperature of molten steel at a certain temperature, and then pull up the stopper rod to let the molten steel flow from the crucible Opening at the bottom to flow out. The molten steel flowing out is fully atomized through the ring-shaped high-pressure gas (Ar gas) nozzle to form a droplet flow, which is directly sprayed onto the high-speed rotating water-cooled copper wheel for rapi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com