Solid-liquid separation method and device for multi-material anaerobic fermentation liquid containing kitchen wastes

An anaerobic fermentation liquid and solid-liquid separation technology, applied in the field of kitchen waste treatment, can solve problems such as difficult maintenance, lower working efficiency of filter press, water and mud output indicators, shutdown and maintenance, etc., to save equipment investment costs , Dehydration properties can be improved, and the effect of avoiding oil clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

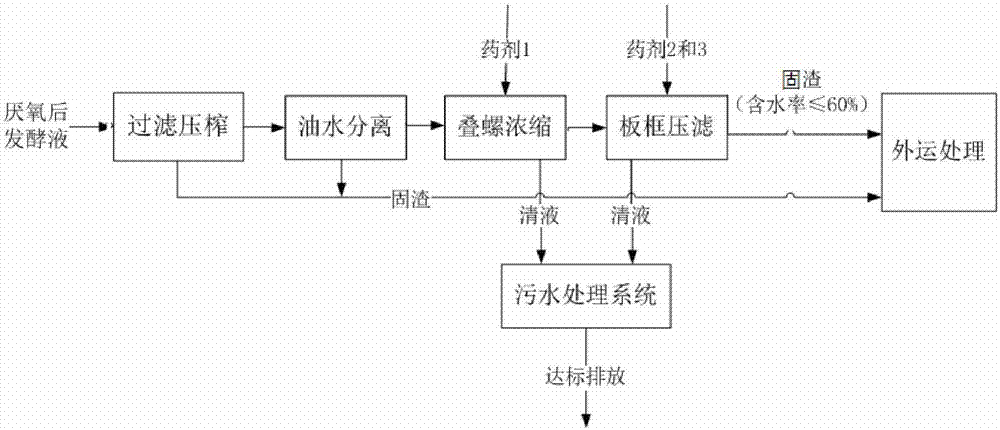

[0051] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown, a kind of multi-material anaerobic fermentation liquor solid-liquid separation method containing kitchen waste, comprises the following steps:

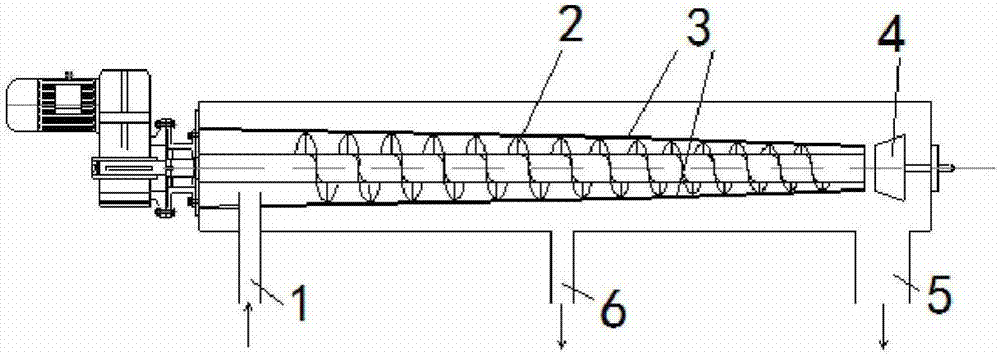

[0052] Step 1), the filtering and pressing step, pump the anaerobic fermented liquid into the feed port 1 of the filtering press, and the conical screw rod 2 pushes the material, and the material passes through the sieve drum 3 for preliminary solid-liquid separation, and the hair and plastic are separated. Impurities such as flakes, fibers, wood chips, and particles; as the impurities advance with the conical screw rod 2, the pitch of the screw gradually decreases, and the diameter of the cavity gradually decreases. Pressing and dehydration in the first zone, the solid slag after pressing is discharged through the slag discharge port 5, and the slurry produced after filtering and pressing is discharged through the first discharge...

Embodiment 2

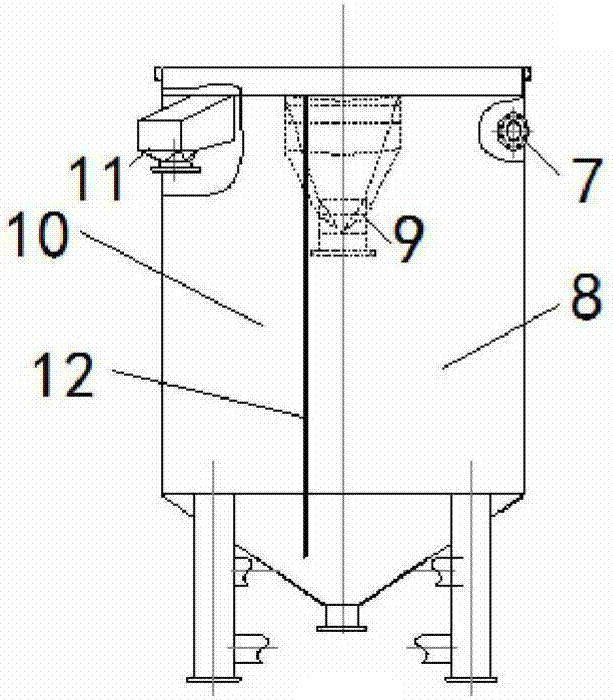

[0068] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a multi-material anaerobic fermentation liquid solid-liquid separation device containing kitchen waste, including a filter press, an oil-water separation tank, a screw stack thickener, a plate and frame filter press, a first conditioning tank and a second conditioning tank , the first discharge port 6 of the filter press is connected to the feed port 7 of the oil-water separation tank through a pipeline, and the overflow port 11 of the oil-water separation tank is connected to the first conditioning tank through a pipeline, and the first conditioning tank is connected to the screw stack through a pipeline and a submersible sewage pump The feed port 13 of the concentrator, the second discharge port 16 of the screw stack thickener is connected to the second conditioning tank through pipelines, and the second conditioning tank is connected to the feed port 20 of the plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com