Pushing device for extraction of formation fluid

A technology of formation fluid and push-back device, which is used in surveying, wellbore/well components, earth-moving drilling, etc., can solve the problems of inconvenient installation and use, unreasonable oil control, large space occupation, etc., and achieves convenient disassembly. , Control the oil circuit and fluid channel is reasonable, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

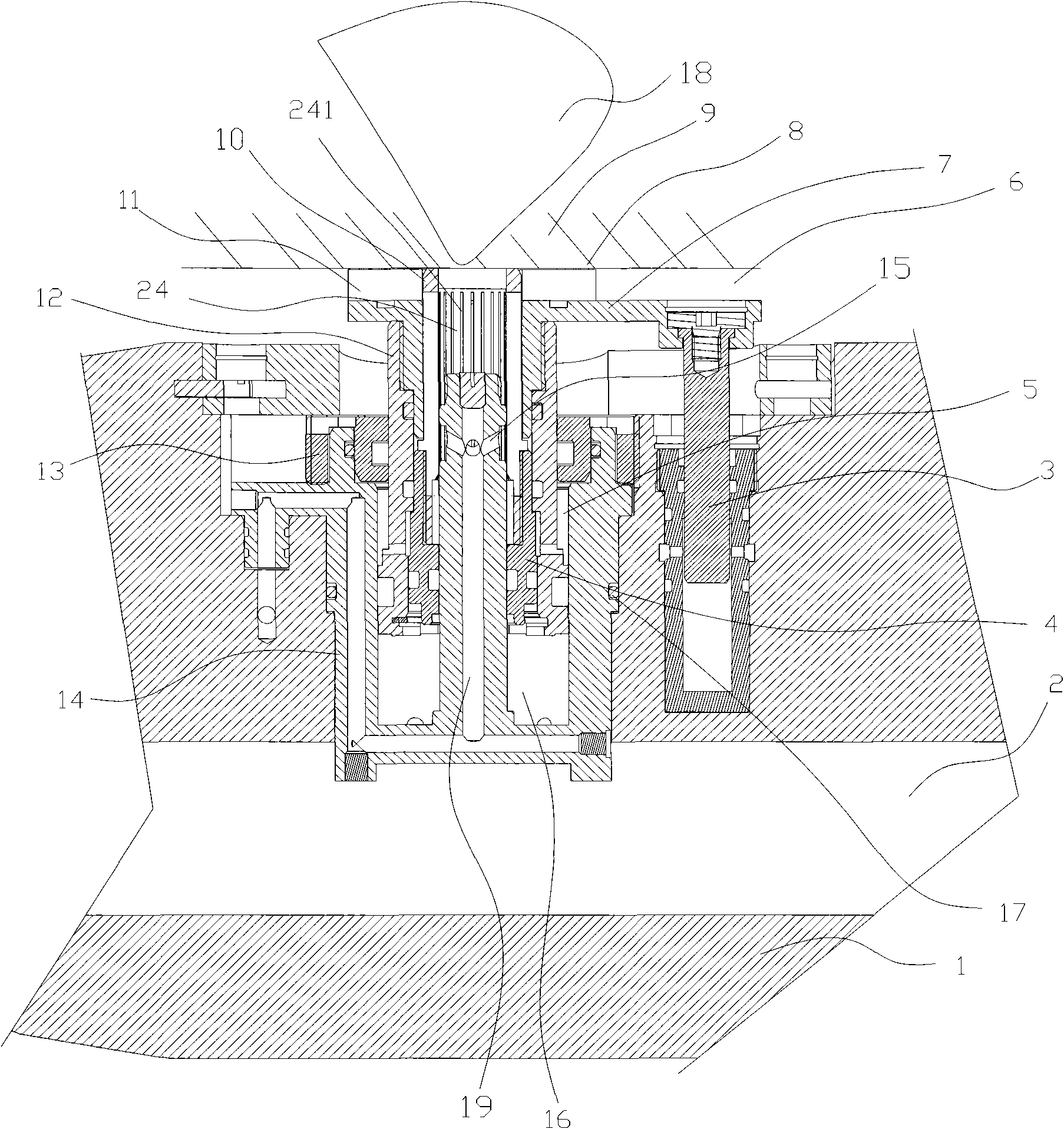

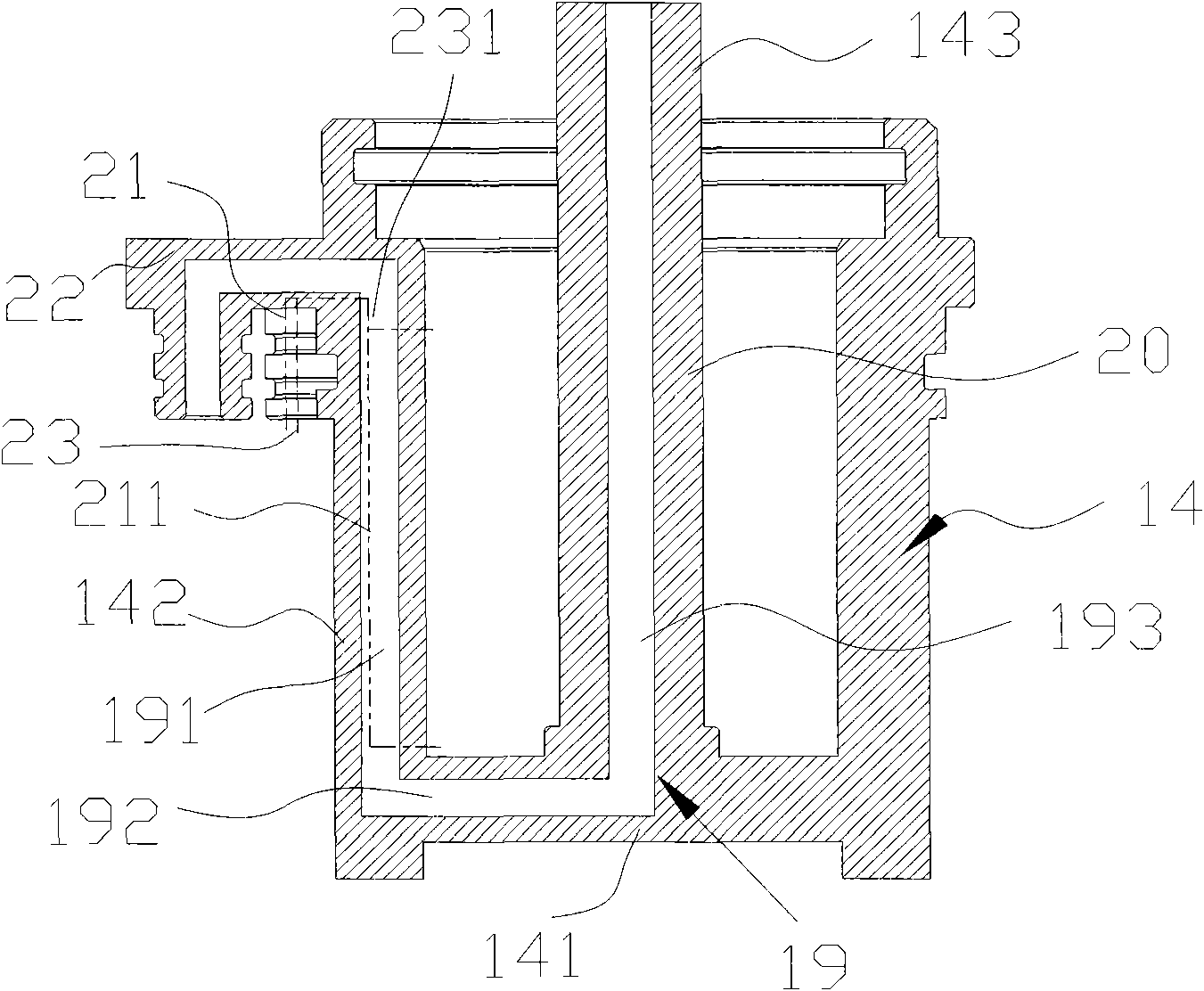

[0019] like Figures 1 to 3 As shown, the present invention includes: a master cylinder 14, the master cylinder 14 is fixedly mounted on the drill collar base 1 through the locking nut 13, and the outside of the side wall 142 of the master cylinder 14 is provided with a sealing structure for forming a sealing structure with the drill collar base 1 The sealing ring 17 of the drill collar base body 1 is provided with an internal circulation channel 2 for fluid circulation. An axially extending central guide rod 20 is disposed at the bottom 141 of the main cylinder 14 . A first push piston 4 and a second push piston 12 are sequentially sleeved on the center guide rod 20 , and the push probe 7 is arranged on the The second pushes against the piston 12 .

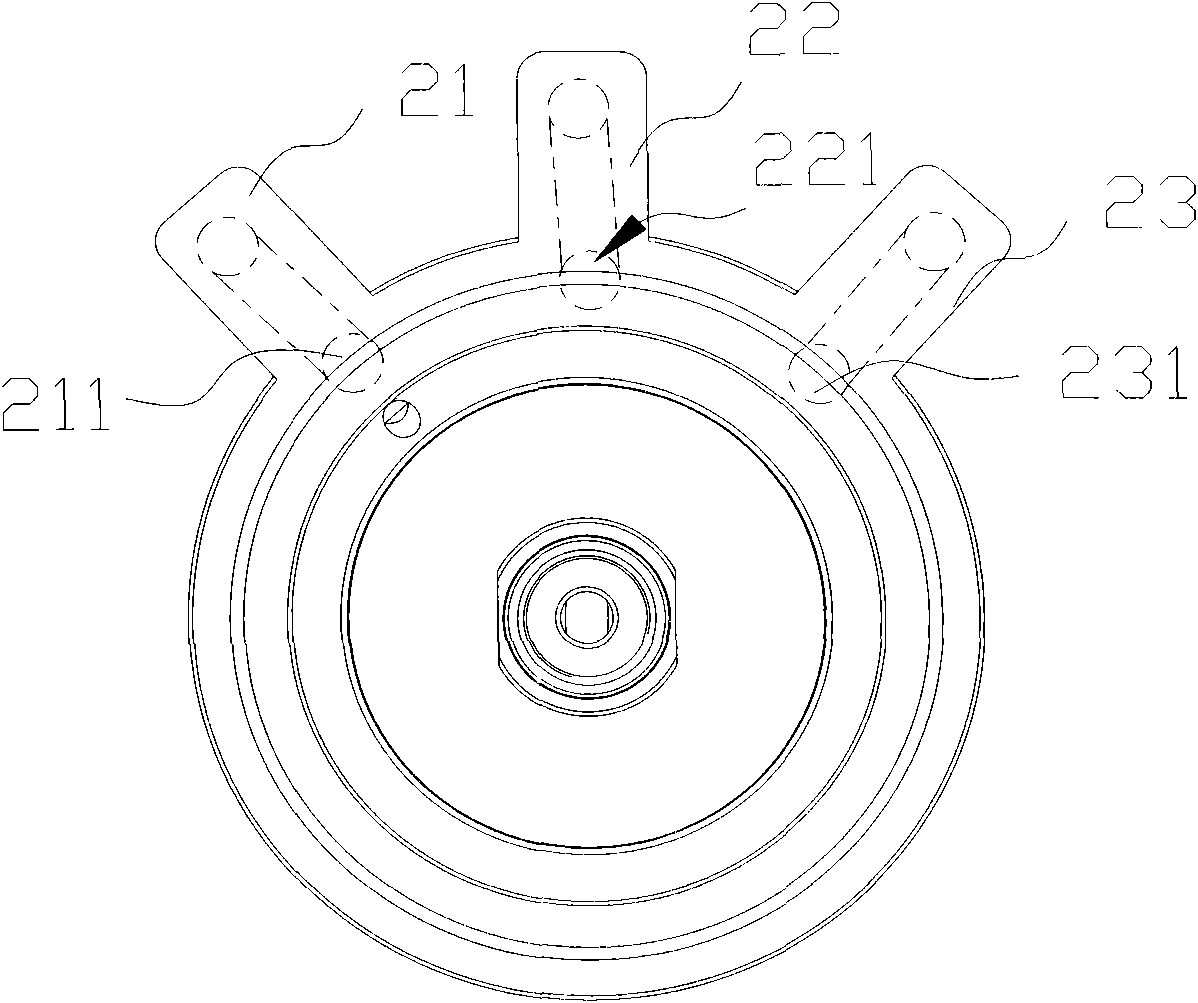

[0020] An opening oil port 21 , a formation fluid port 22 and a shrinking oil port 23 are provided on the side wall 142 of the main cylinder block 14 . The channel 211 is communicated with the open oil cavity 16 of the main cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com