Filter cloth model selection experiment machine

A technology of experimental machine and filter cloth, which is applied in the field of filter press, can solve the problems of large manpower, material and financial resources, easy access to site restrictions, and large volume of the whole machine, so as to facilitate transportation, reduce material loss, and small filtration area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawings and examples.

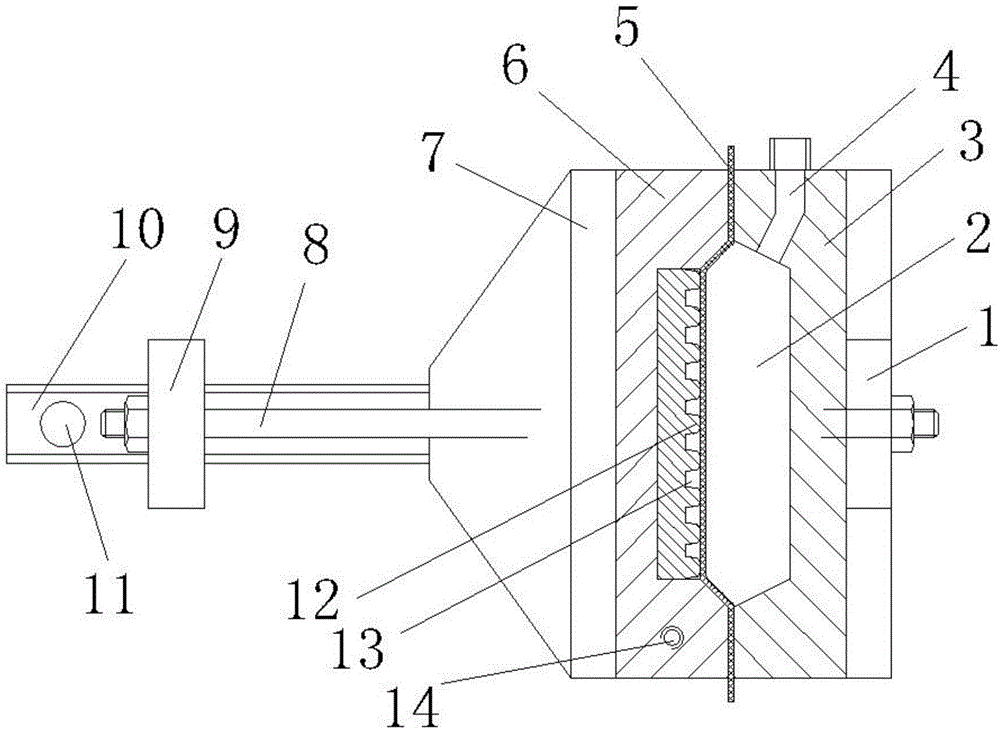

[0017] As shown in the figure, a filter cloth type selection test machine includes a supporting base plate 1, a pressing plate 7, and a bolt pull rod 8, and is characterized in that a feed plate 3 is fixed inside the supporting base plate 1, and the pressing plate 1 is fixed on the inner side. A filter plate 6 is fixed on the inner side of the tight plate 7, and a filter cloth 5 is installed between the feed plate 3 and the filter plate 6, and is pressed together to form a closed filter chamber 2. The feed plate 3 is provided with a through To the feed port 4 of the filter chamber, the central position of the filter plate 6 is provided with a number of evenly distributed small bumps 12, and a filtrate channel 13 is formed between the small bumps 12, and the filter plate 6 also has There is a liquid outlet 14 leading from the filtrate channel 13 to the outside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com