Electric furnace flue gas dust removal device capable of storing flue gas

A dust removal device and flue gas technology, applied in the direction of furnace, furnace components, process efficiency improvement, etc., can solve the problems of large material consumption, increased investment costs and operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

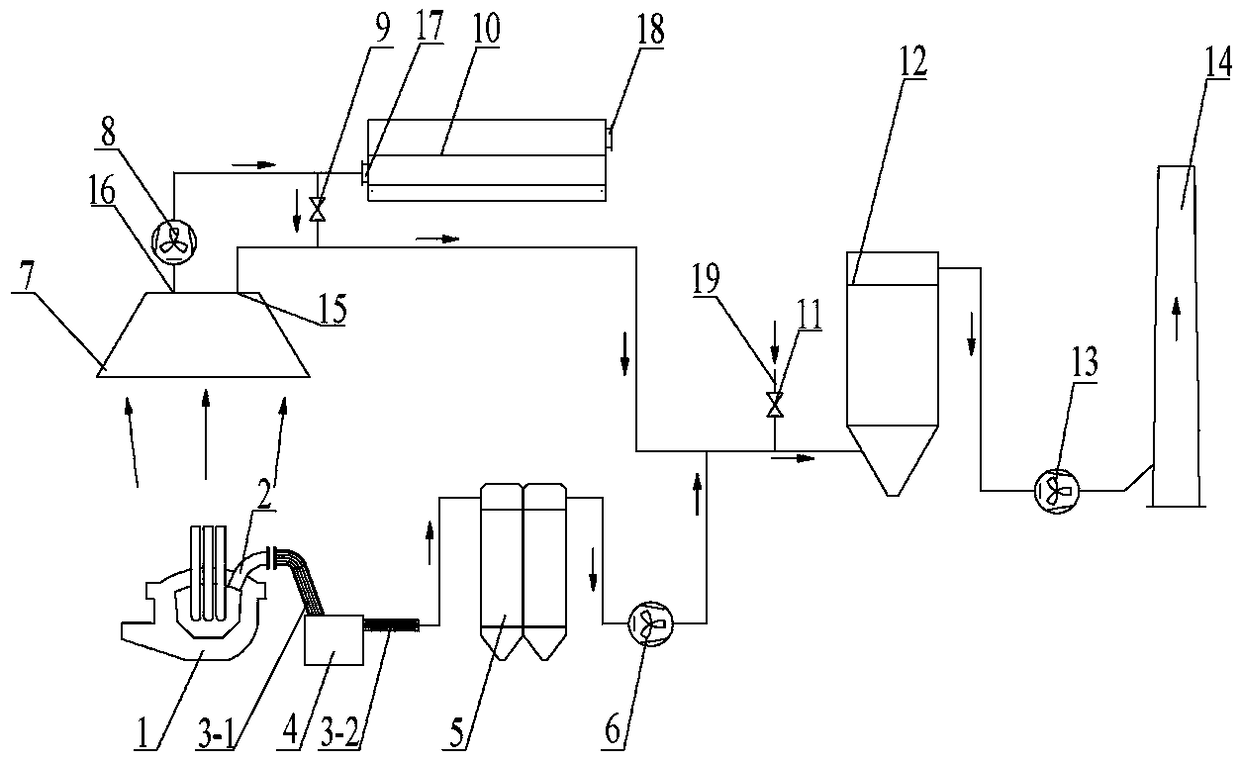

[0010] Such as figure 1 As shown, the present invention comprises an electric furnace 1, a furnace hole exhaust pipe 2, a first water-cooled flue 3-1, a second water-cooled flue 3-2, a combustion settling chamber 4, an air cooler 5, a booster fan 6, a roof Cover 7, smoke storage fan 8, bypass valve 9, flue gas storage pipe 10, safety valve 11, bag filter 12, dust removal fan 13, chimney 14, a roof cover 7 is set directly above the electric furnace 1, and there is a gap with the electric furnace 1 A certain vertical distance; after the straight outlet 15 of the roof cover 7 is connected to the booster fan 6, the bag filter 12, the dust removal fan 13, and the chimney 14 are sequentially connected through pipelines, and a safety valve 11 is set between the roof cover 7 and the bag filter 12 , The roof cover 7 is provided with a bypass port 16, the bypass port 16 is connected with the flue gas storage pipe 10 after the smoke storage fan 8, and the bypass valve 9 is connected betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com