Refillable container with a zero waste dispensing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 100

[0086]As described above, instead of relying upon the force of gravity to pour the contents out of the collapsible insert 110 upon tipping of the FIG. 1A container 20, the thick-liquid embodiment 100 utilizes varying efficient but complex extractions mechanisms to move the thick liquid within the insert 110 through the discharge cap 106 and out of the container 100.

[0087]A first extraction mechanism is shown generally in FIGS. 15-31. For convenience, this first extraction mechanism will be referred to herein as a helical track extraction mechanism. (As described above, for purposes herein, the phrase “helical track” is intended to include both a groove defined to descend below an inside surface 122 of the shell as well as a ridge defined to extend above the inside surface 122 of the shell. It is expected that most helical track extraction mechanism embodiments will be in the form a groove.)

[0088]As shown in FIG. 15 a preferred embodiment includes a first helical track 124 and a seco...

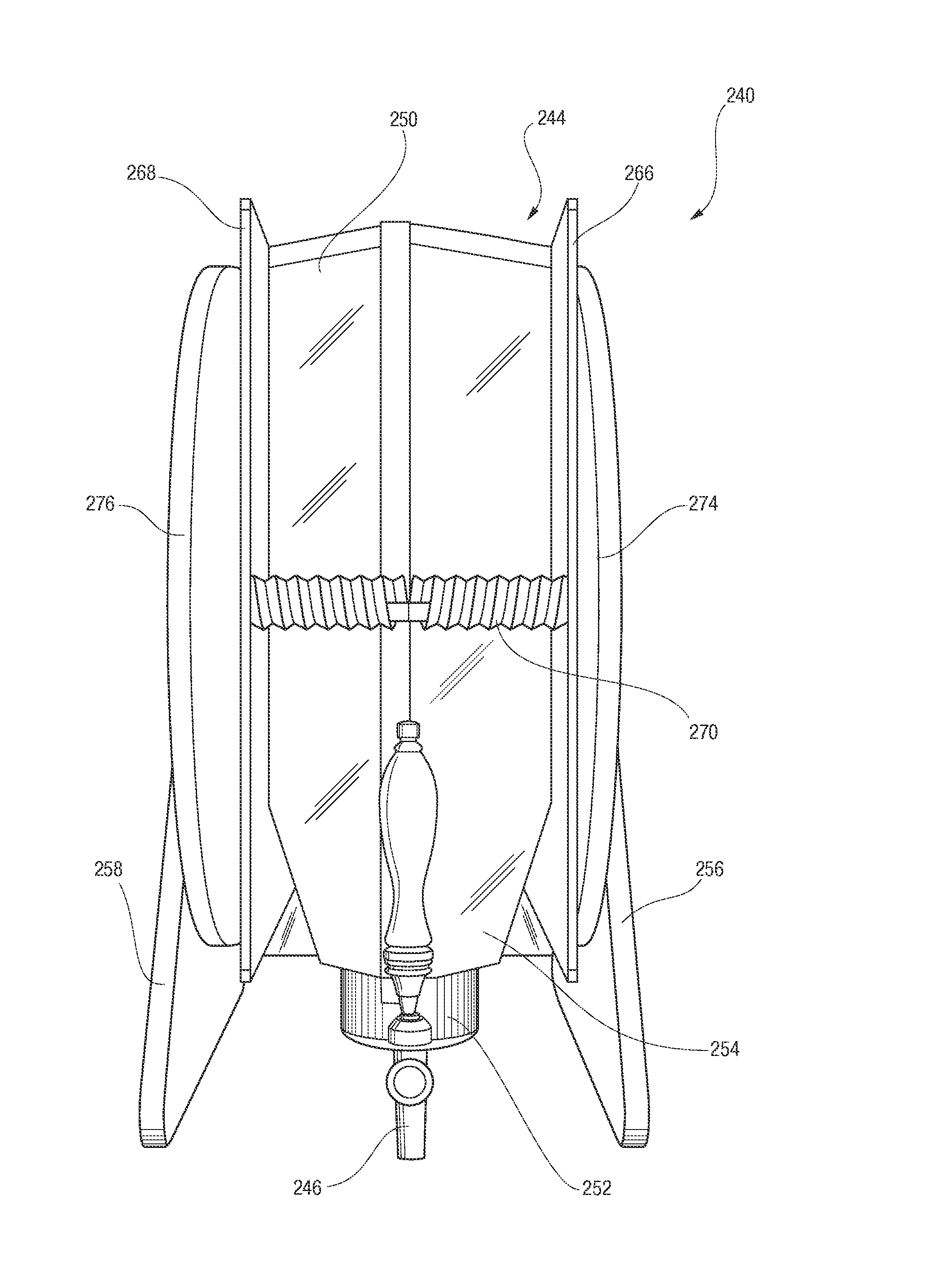

embodiment 240

[0102]FIG. 34 shows that helical axle refillable container 242 may be pivotally mounted between a first pivot base 256 and a second pivot base 258. The semi-rigid outer shell 242 is pivotally secured between the pivot bases 256, 258 so the shell 242 may be deployed in a dispensing mode as shown in FIG. 34 or in a refill mode as shown in FIG. 35. The outer shell 242 also includes a front wall 260, top wall 262, a bottom wall 264, a first side wall 266 and a second side wall 268 (shown only in FIG. 36). In this helical axle embodiment 240, the side wails 266, 268 may be rigidly secured to the front, top and bottom walls 260, 262, 264 so that opposed compression plates may be secured within the shell 242.

[0103]Alternatively, and as shown in FIGS. 34-36, and FIGS. 38, 39, the side walls 260, 262 may be slidably secured to the front, top and bottom walls 260, 262, 264 to thereby serve as compression plates 266, 268 to apply pressure to the collapsible insert 250. As shown best in FIGS. 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com