Method for processing chrome wastewater from steel surface passivation process

A steel surface and treatment method technology, which is applied in the field of industrial wastewater treatment, can solve the problems of inconvenient operation management, secondary environmental pollution, and high operating costs, and achieve the effects of simple recycling process, low equipment investment, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

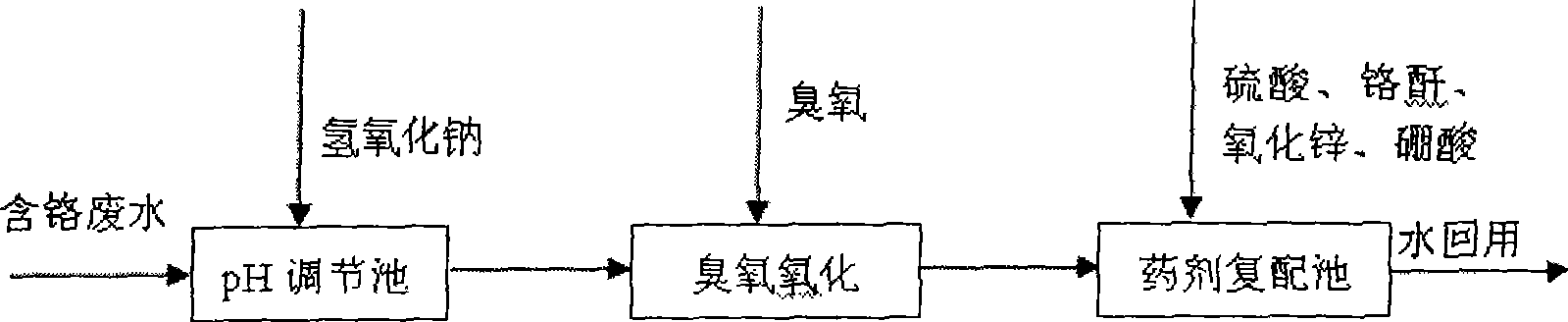

[0023] Take the chromium-containing waste water produced by the surface passivation of silicon steel of Wuhan Iron and Steel (Group) Company as an example below in conjunction with the accompanying drawings to further explain the present invention.

[0024] The specific method is:

[0025] (1) Pretreatment: Add sodium hydroxide to the pH adjustment tank to adjust the pH value of the chromium-containing wastewater to 6-8, and perform mechanical stirring at the same time to speed up the reaction speed and balance the water quality;

[0026] (2)O 3 Oxidation reaction: According to the measured concentration of trivalent chromium in the chromium-containing wastewater, a strong oxidant O is introduced into the pH-adjusted chromium-containing wastewater. 3 , O 3 The input amount is 20-100mg / L, the reaction time is 1-3 hours, and the trivalent chromium is oxidized to hexavalent chromium, and the reaction formula is 2Cr 3+ +O 3 +4H 2 O=Cr 2 o 7 2- +8H + ;

[0027] (3) Reagen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com