Method for recycling metal from waste acid etching liquid

An acid etching solution and metal technology, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of large caustic soda consumption, huge investment in one-time construction, and small audience, so as to achieve stable product quality and low investment cost , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

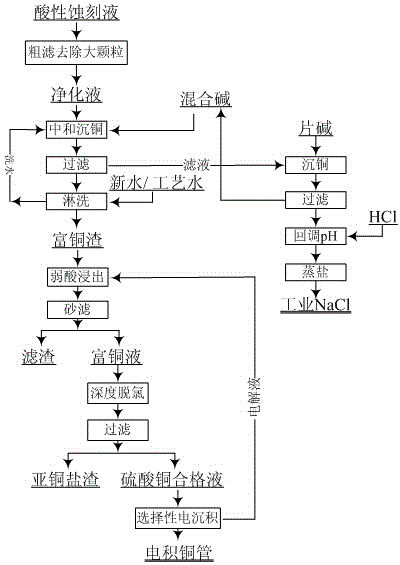

Method used

Image

Examples

Embodiment 2

[0057] 1) Construction in the workshop in sequence: 1 set of 1t steam boiler per hour, 1 set of three-effect evaporator that can evaporate 1t of water per hour, 1 set of 20m³ copper sinking tank, 1 set of vacuum belt filter, 100kg copper extraction per hour One extraction line, one set of selective electrodeposition equipment with an annual output of 300t copper precipitation.

[0058] 2) Preset the process water enough to submerge the stirring paddle in the copper precipitation tank, and add caustic soda to it to supersaturation; start the addition of etching solution; continuously add mixed alkali to the copper precipitation tank according to the mass ratio of 2:1 , and continue to add acidic etching waste liquid; stop adding mixed alkali when the liquid level in the copper sinking tank reaches 60% of the total liquid level depth, and continue to add etching solution until the pH of the slurry in the copper sinking tank drops to 6.5;

[0059] 3) The obtained slurry is suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com