Dry process and wet process combined smoke gas desulfuration system

A technology of desulfurization system, dry method and wet method, applied in the field of dry method and wet method combined flue gas desulfurization system, can solve the problems of difficult wastewater treatment, high operation cost, high investment cost, etc., and achieve lower flue gas temperature, lower chimney corrosion, The effect of reducing the amount of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

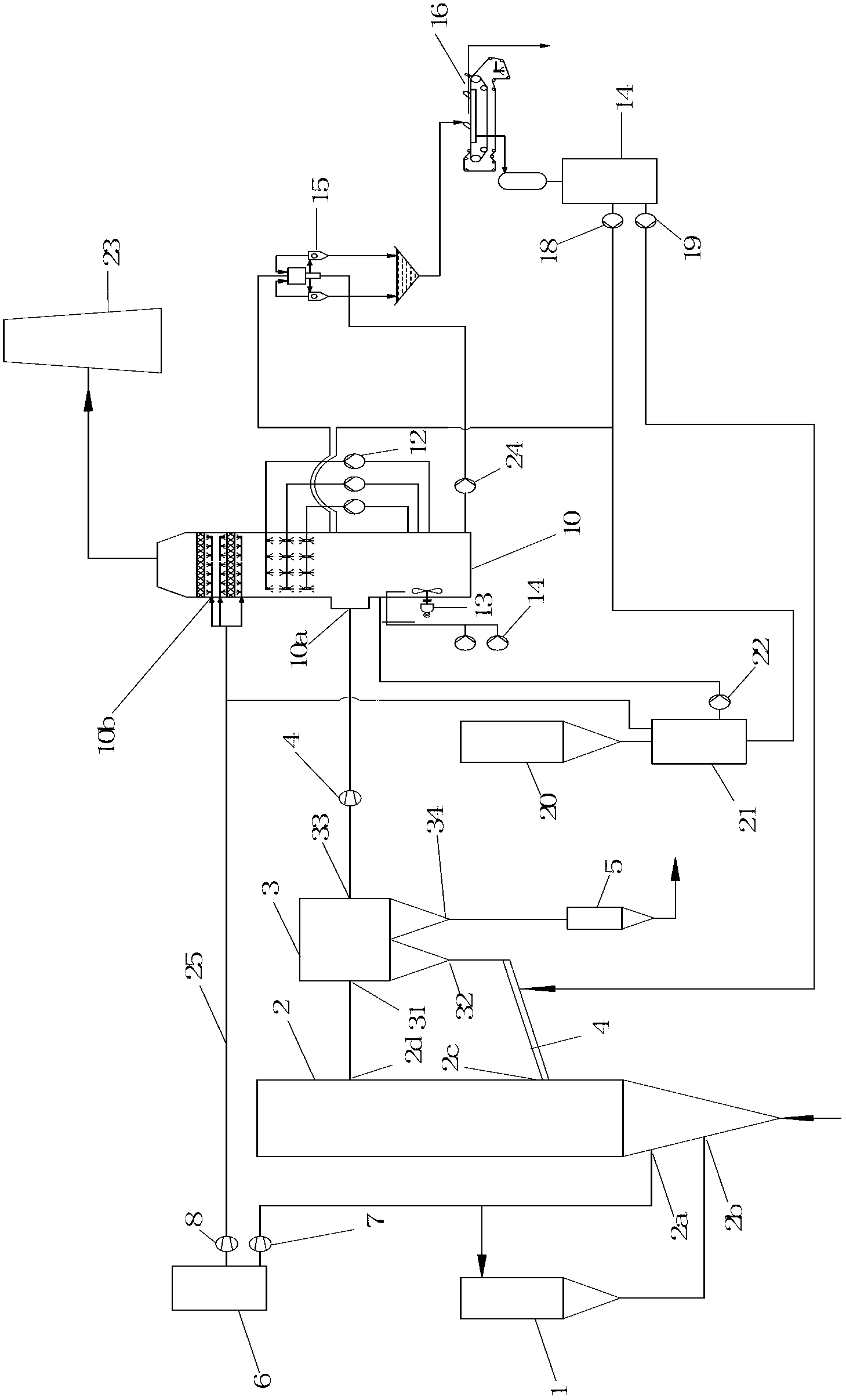

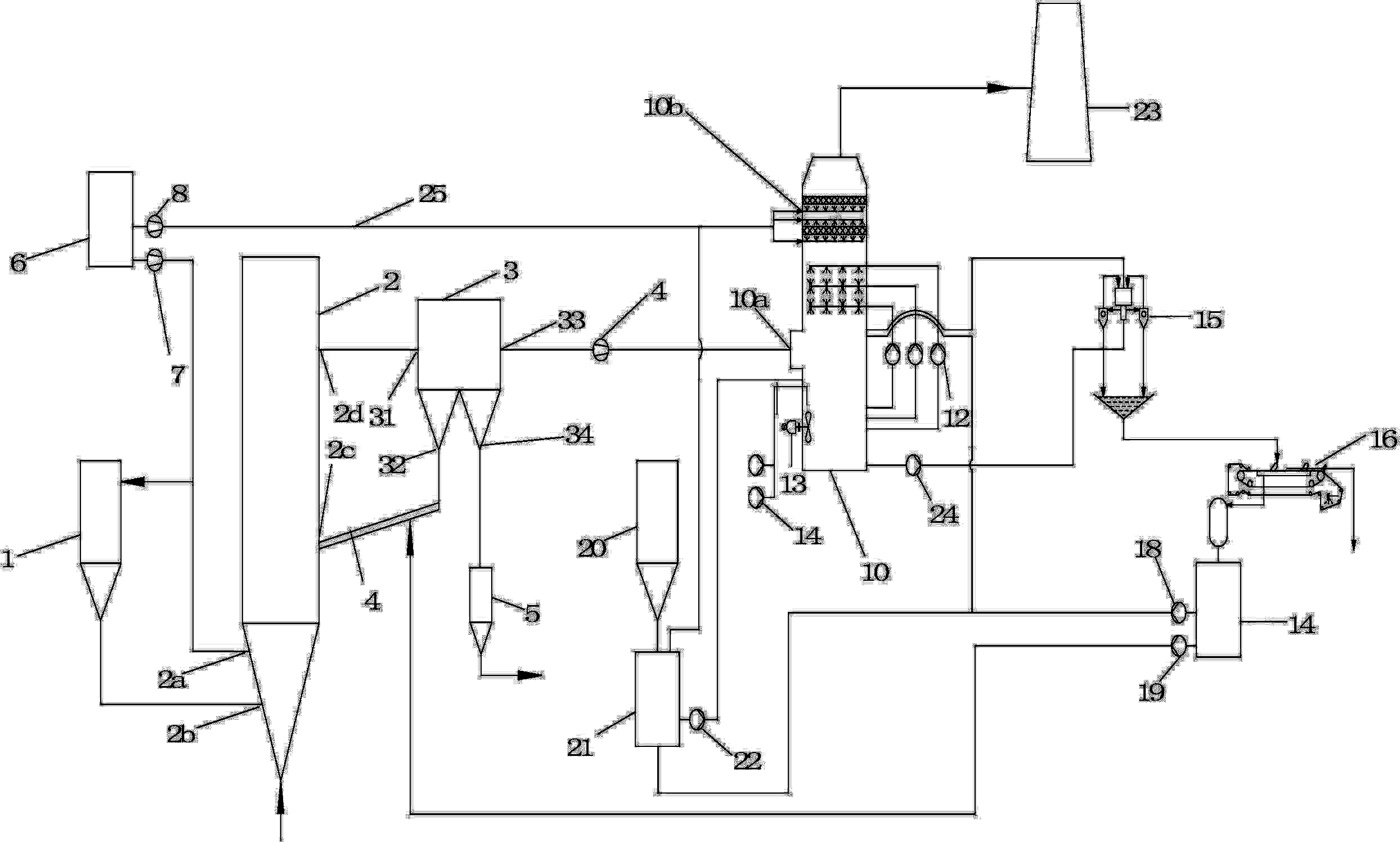

[0027] The figure shows a combined dry and wet flue gas desulfurization system, which consists of a dry desulfurization system and a wet desulfurization system. The wet desulfurization system includes a limestone powder bin 20, a return water tank 17, and a wet absorption tower 10 And limestone slurry tank 21. The wet absorption tower 10 also includes a mist eliminator 11 , a circulating pump 12 , an absorption tower agitator 13 and an oxidation blower 14 . The limestone powder bin 20 is connected to the wet absorption tower 10 , and a limestone slurry tank 21 is also provided between the limestone powder bin 20 and the wet absorption tower 10 . The wet absorption tower 10 is respectively connected with a gypsum dehydrator 15 and a chimney 23 . A gypsum discharge pump 24 is also provided on the pipeline between the wet absorption tower 10 and the gypsum cyclone station 15 . The other end of the gypsum cyclone station 15 is connected with a belt dehydrator 16 and a return wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com