Method for extracting ketene dimer by rectifying residues and pumped liquid

A diketene and residue technology, which is applied in the field of acetic acid cracking to prepare diketene, can solve the problems of waste of fuel and effective substances, material loss, pollution, etc., and achieve the effects of increasing production, solving residue emission reduction, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

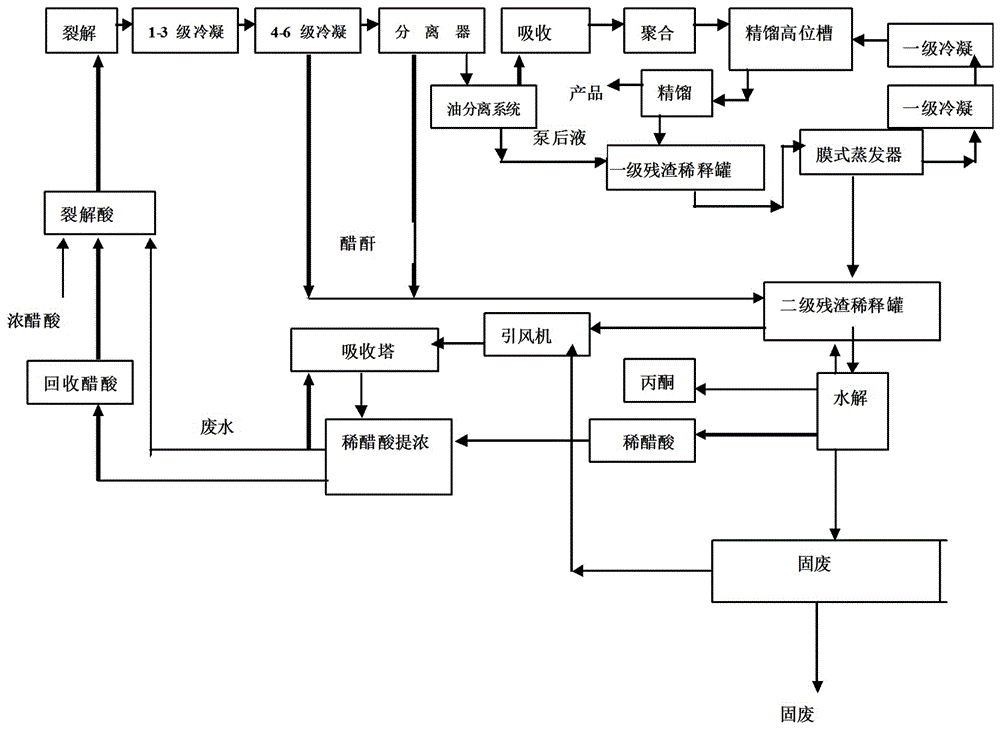

[0037] Such as figure 1 As shown, the present invention provides a production method for extracting diketene from a mixture of distillation residue and pump liquid, which includes the following steps:

[0038] a. Prepare 99.8% concentrated acetic acid and 85% dilute acetic acid recovered by the system into pyrolysis acid in proportion, and put 1.8T 96% pyrolysis acid into the cracking furnace. The outlet temperature of the cracking furnace is controlled at 710-730 degrees and the pressure is 75— 80 KPa. The ketene gas condensed by No. 1-6 condensers is sent to the polymerization section to obtain 0.846 T crude diketene, and then rectified and purified to obtain 0.765 T diketene finished product, producing a first-level residue 0.085T.

[0039] b. Mix the primary residue produced after the rectification section with the pump liquid produced by the oil separation system (the crude diketene content is 40%, the anhydride content is 40-50%, and the rest is acetic acid) at a ratio of 2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com