Zero waste dosing method and apparatus for filling containers of liquids

A liquid volume and container technology, applied in liquid distribution, transportation or transfer devices, liquid bottling, distribution devices, etc., can solve the problems of rising costs, cost problems, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

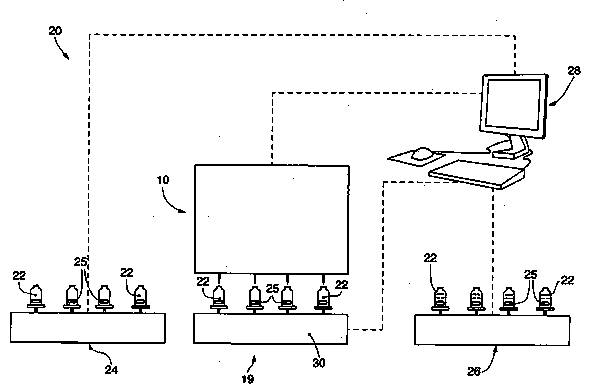

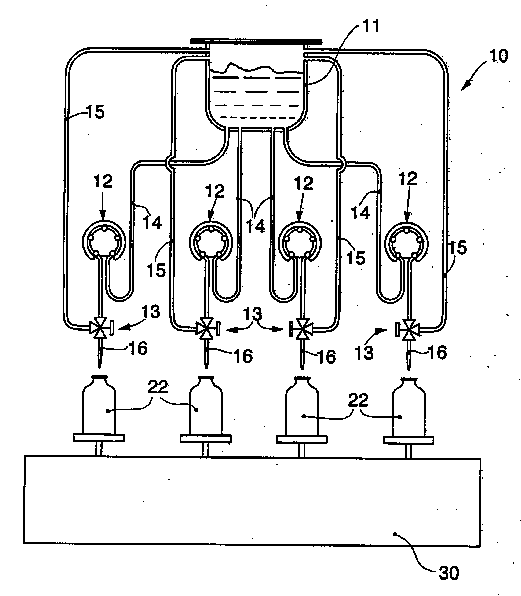

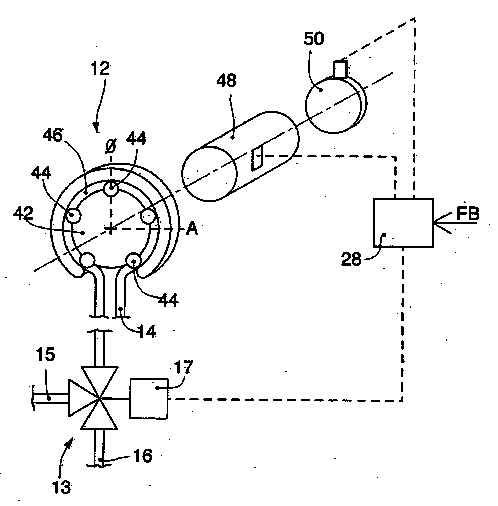

[0062] The example shown in the accompanying drawings is a machine 20 for accurately filling a plurality of containers 22 with a liquid, which has a dosing device 10 ( figure 2 ), the first station 24 and the second station 26; the first station 24 works upstream (only for the time sequence) of the container 22 filling step, and is used to measure the tare weight of the container 22; the second station 26 is in the dosing device 10 Downstream work to measure the gross weight of the container 22 after it has been filled.

[0063] In a variant, the first station 24 is independently and physically separated upstream of the dosing device 10, for example as figure 1 shown. In other variants, the first station 24 is associated or integrated with the dosing device 10 .

[0064] The machine 20 is also connected to or comprises an electronic information processor 28 or similar processing means or control directing means for at least directing and controlling the dosing device 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com